High-efficiency all-solid-state thulium laser packaging module

A laser packaging, all-solid-state technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of reducing thermal lens effect, water vapor condensation on optical sections, reducing thermal stress of crystals, etc., to improve pumping energy Limiting, lowering temperature, reducing the effect of maximum stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

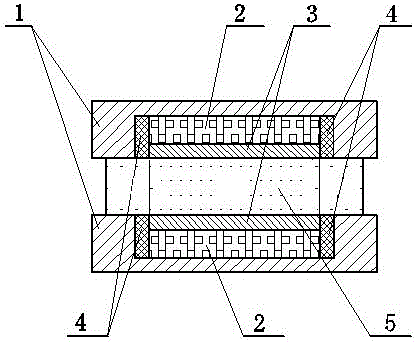

[0018] like figure 1 As shown, the high-efficiency all-solid-state thulium laser packaging module of the present invention includes an auxiliary heat sink 1, two groups of TEC refrigeration modules 21 and 22, a cooling heat sink 3, two groups of heat insulating materials 41 and 42, and strip-shaped Tm:YAG crystal 5 . Laser crystal 5 adopts a strip-shaped Tm:YAG and YAG bonded crystal with a specification of 4×4×10mm, in which the non-doped parts of B and C at both ends are each 2.5mm long, and the doped part of A in the middle is 5mm long. The bonded crystal avoids The Tm:YAG laser has a higher concentration of lower energy level particles for the absorption of the oscillating laser due to the quasi-three-level operation, which improves the laser efficiency. The area around the crystal A is closely combined with the cooling heat sink through the indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com