Piston-type roller iron scrap adsorption trolley

A piston-type, iron filings technology, applied in the direction of cleaning carpets, cleaning floors, manual sweeping machines, etc., can solve the problems of manpower consumption, loss of automatic adsorption of iron filings, etc., to improve work efficiency, eliminate safety hazards, and solve power on and off problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

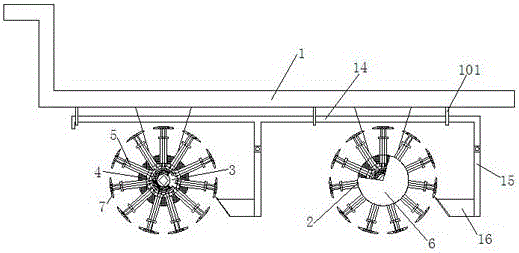

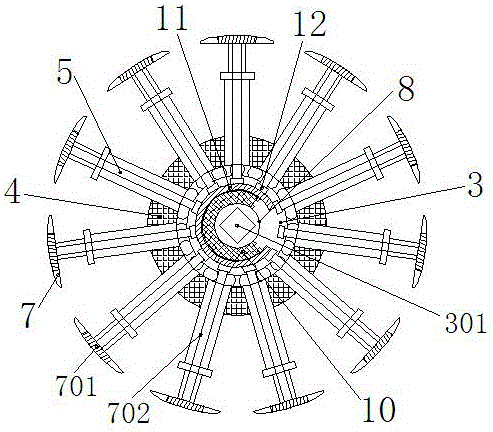

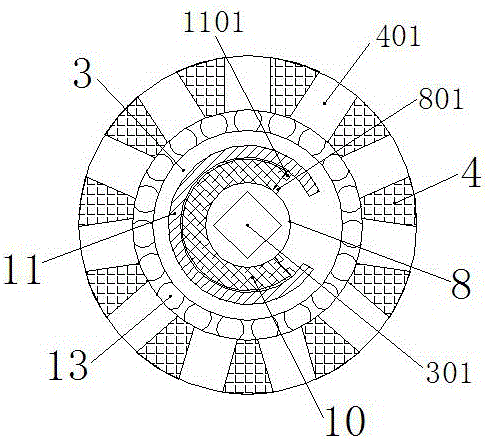

[0030] As shown in the figure, a piston-type roller iron chip adsorption cart includes a frame 1 and a wheel 2 arranged at the bottom of the frame 1. The wheel 2 is composed of an inner ring 3, an outer ring 4, and several pistons. The rod 5 and the end cover 6 fixedly arranged on the side walls of the inner ring 3 and the outer ring 4 for fixing the piston rod 5 are composed of a ball 13 between the inner circumference of the outer ring 4 and the outer circumference of the inner ring 3 Together they form rolling bearings;

[0031] The side wall of the outer center ring 4 is provided with several slots 401 matched with the rod body of the piston rod 5 along its circumference, and an installation cavity for accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com