Drug-adding dehydration reduction system

A technology of a dosing device and a sludge dehydrator, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of easy hydrolysis of sludge, difficult storage and transportation, and high moisture content of sludge cake, so as to reduce sludge volume, avoid adding wrong dosage, and reduce the effect of sludge moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The above object of the present invention and its structural and functional characteristics will be described with reference to the preferred embodiments of the accompanying drawings.

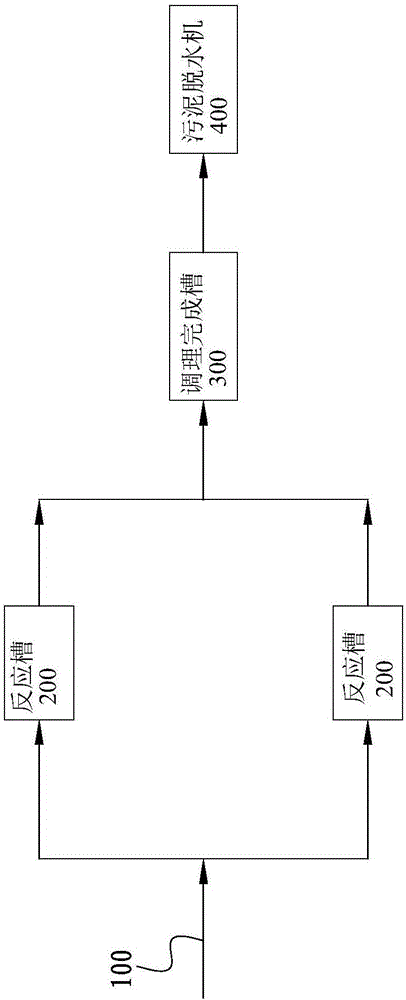

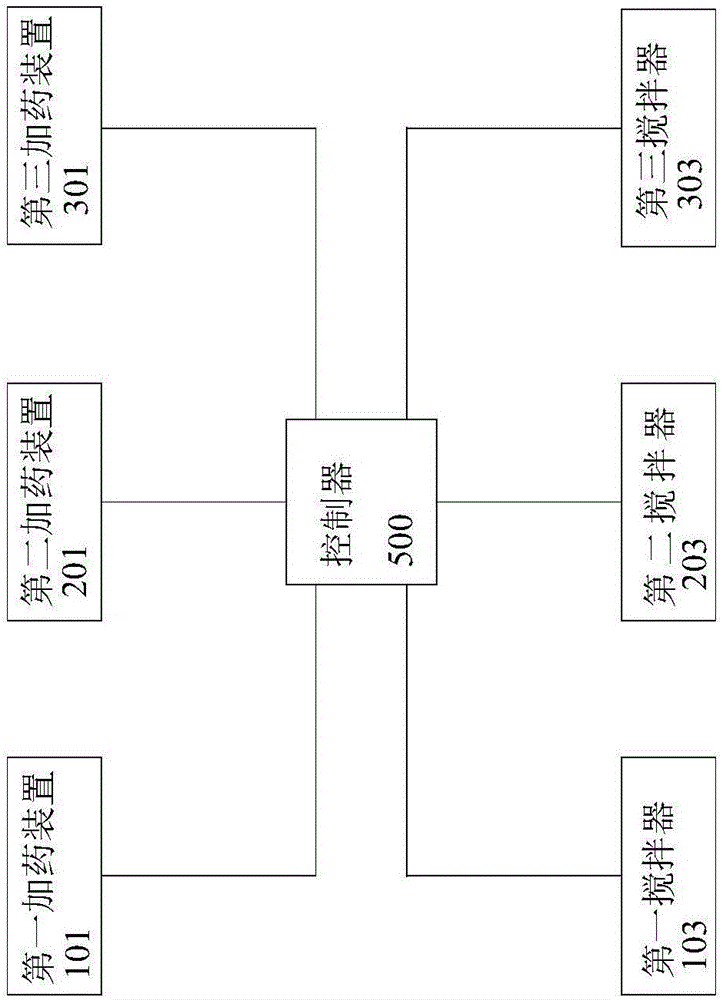

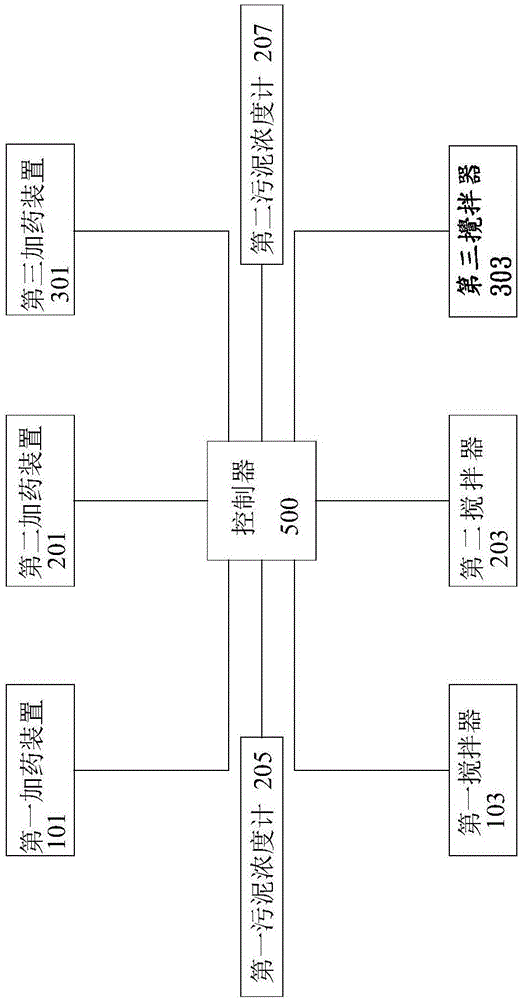

[0042] see Figures 1 to 2 , is the schematic diagram of the chemical dosing, dehydration and weight reduction system of the present invention and the block diagram of the first embodiment. As shown in the figure, the chemical dosing dehydration and weight reduction system of the present invention is used to treat sludge (for example, those with a water content > 80%) Sludge), the dosing dehydration and weight reduction system includes: a sludge receiving pipe 100 , at least one reaction tank 200 , a conditioning completion tank 300 , a sludge dewatering machine 400 and a controller 500 . In this embodiment, the controller 500 is described as a PLC controller, but it is not limited to this, and may be any type of controller during specific implementation. And in this embodiment, two rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com