Vertical sludge dryer

A sludge drying and vertical technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of secondary pollution, achieve the effect of efficient heat energy recovery, reduce secondary pollution, and reduce the moisture content of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

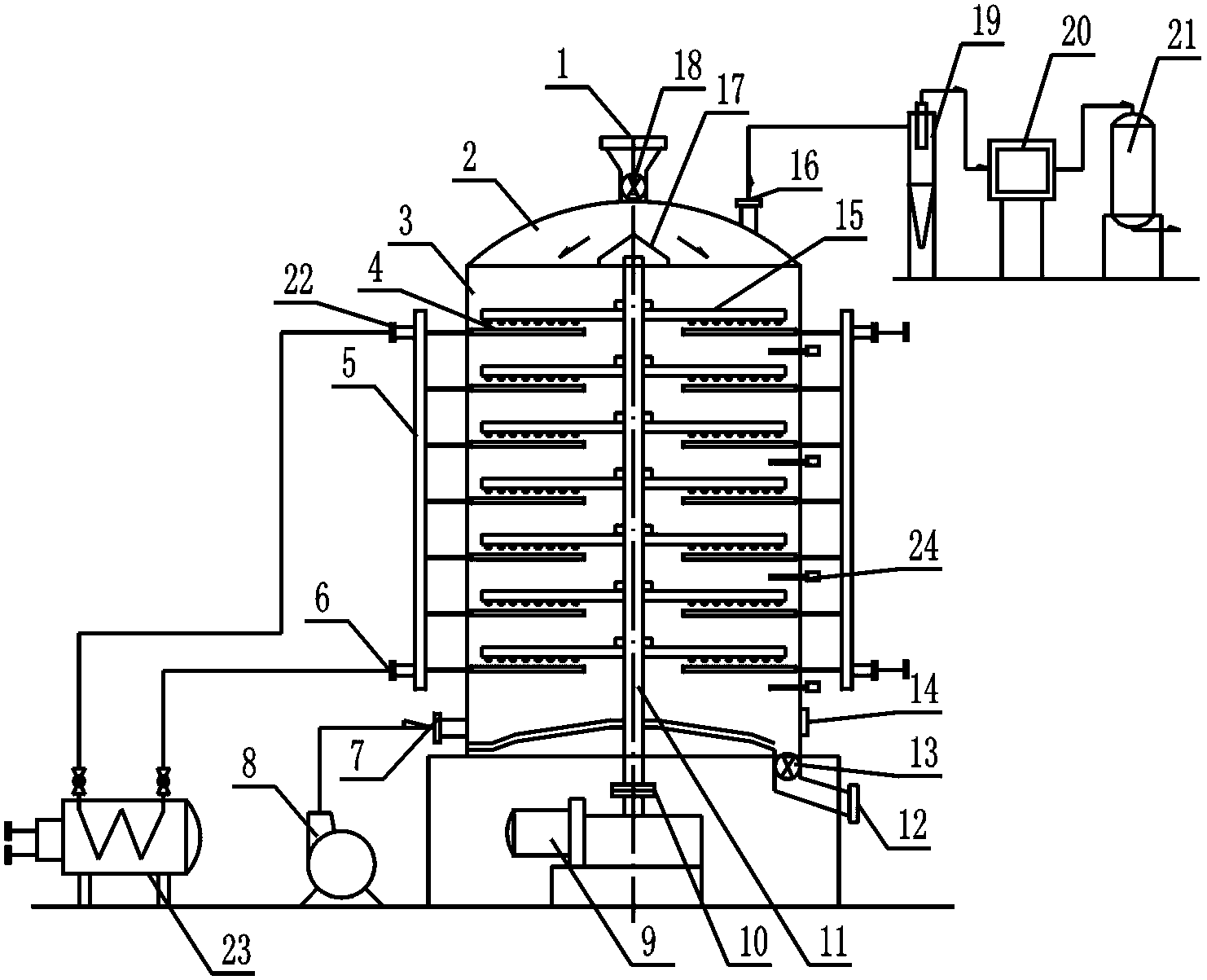

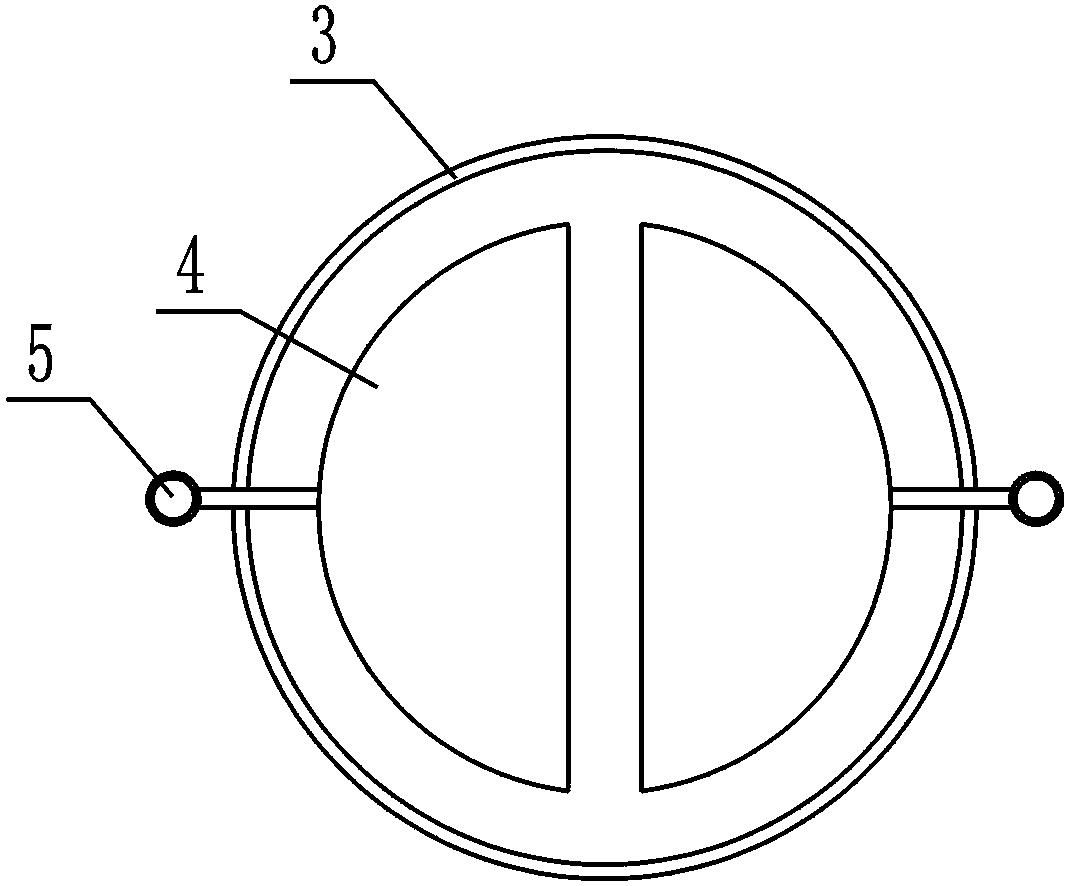

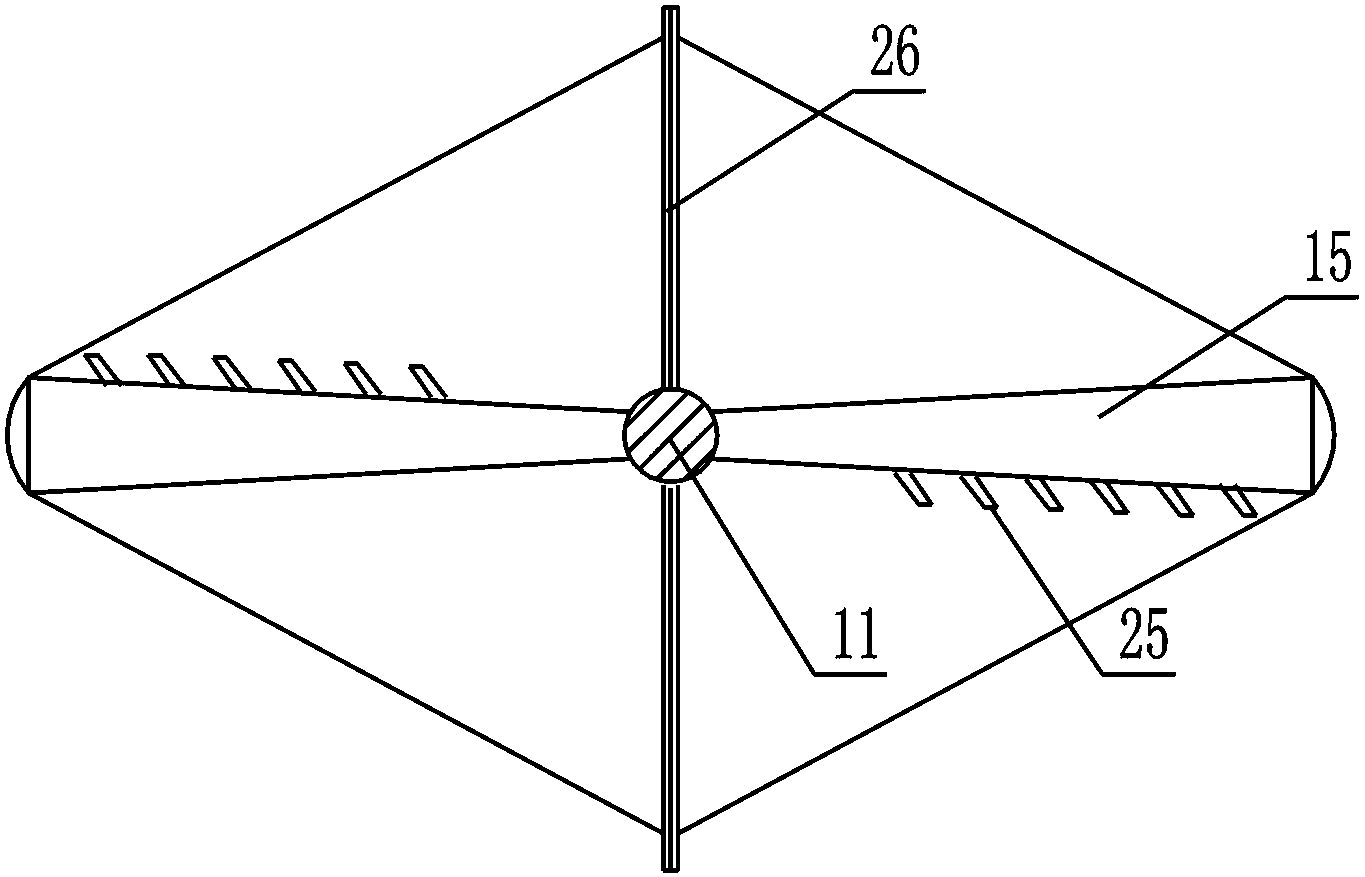

[0016] Example: as figure 1 , figure 2 , image 3 As shown, the present invention includes: a cover 2, a tower body 3, a fixed hot plate 4, a steam main pipe 5, a fan 8, a driving device 9, a rotating arm 15, a waste heat boiler 23, and a cyclone separator 19, a plasma dust collector connected in sequence It is characterized in that: the driving device 9 is arranged at the bottom of the tower body 3, the driving device 9 is connected with the main shaft 11 through the coupling 10, and a rotating arm 15 is installed on the main shaft 11 to rotate The half arm of the arm 15 is fan-shaped, and a symmetrical pull rod 26 is arranged on the rotating arm 15. The main shaft 11 provides power for the rotating arm 15 to rotate.

[0017] The fixed heat plate 4 is in a semicircular shape, the fixed heat plate 4 is communicated with the steam main pipe 5 through a pipeline, and the fixed heat plate 4 transfers heat through the surface to heat the sludge.

[0018] The upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com