Tail gas purification and heat recovery system and method for sludge treatment

A tail gas purification and sludge treatment technology, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, separation methods, etc. Human living environment hazards and other issues, to achieve the effect of quickly and effectively realizing heat recovery, improving efficiency, and eliminating secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

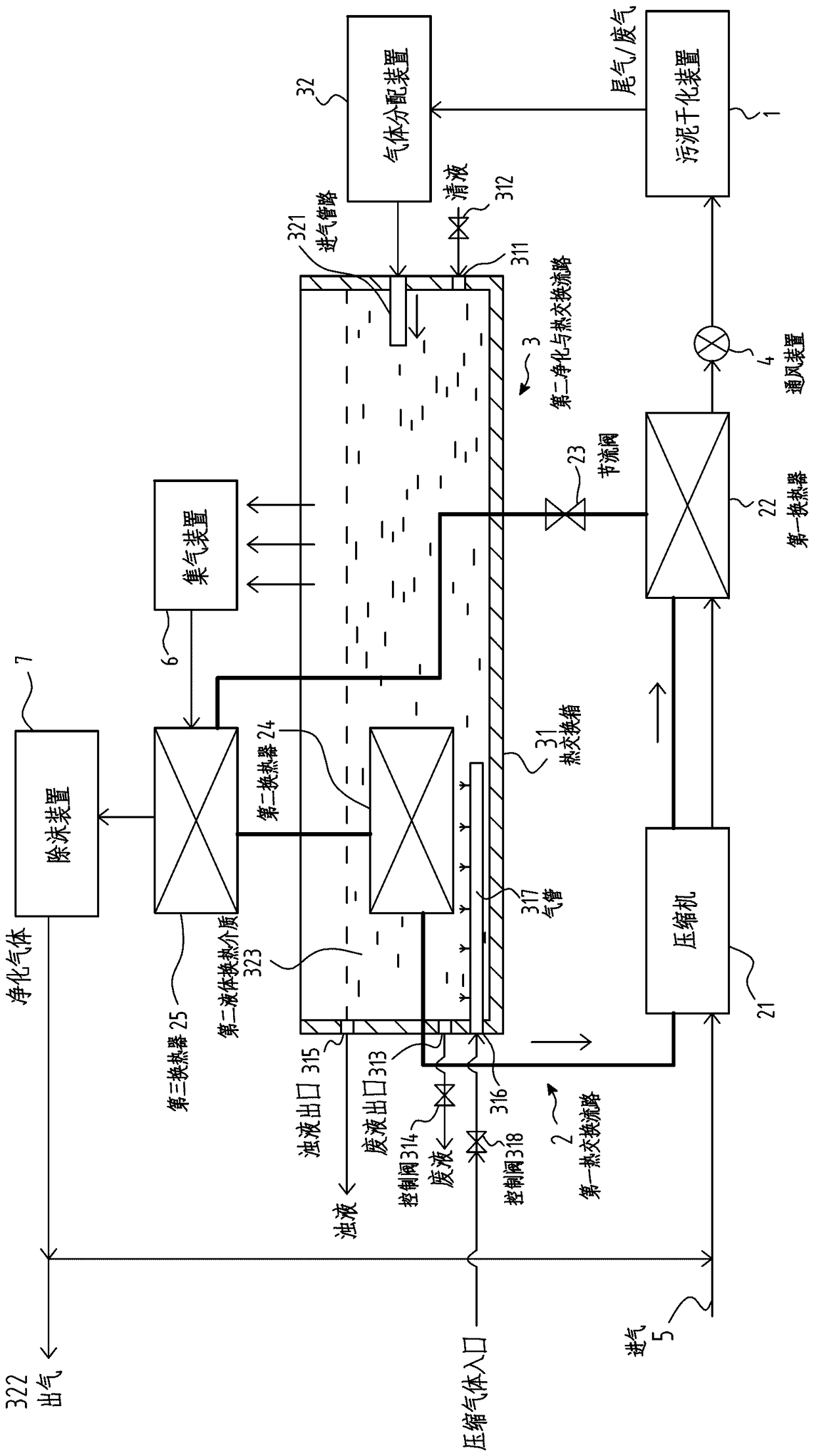

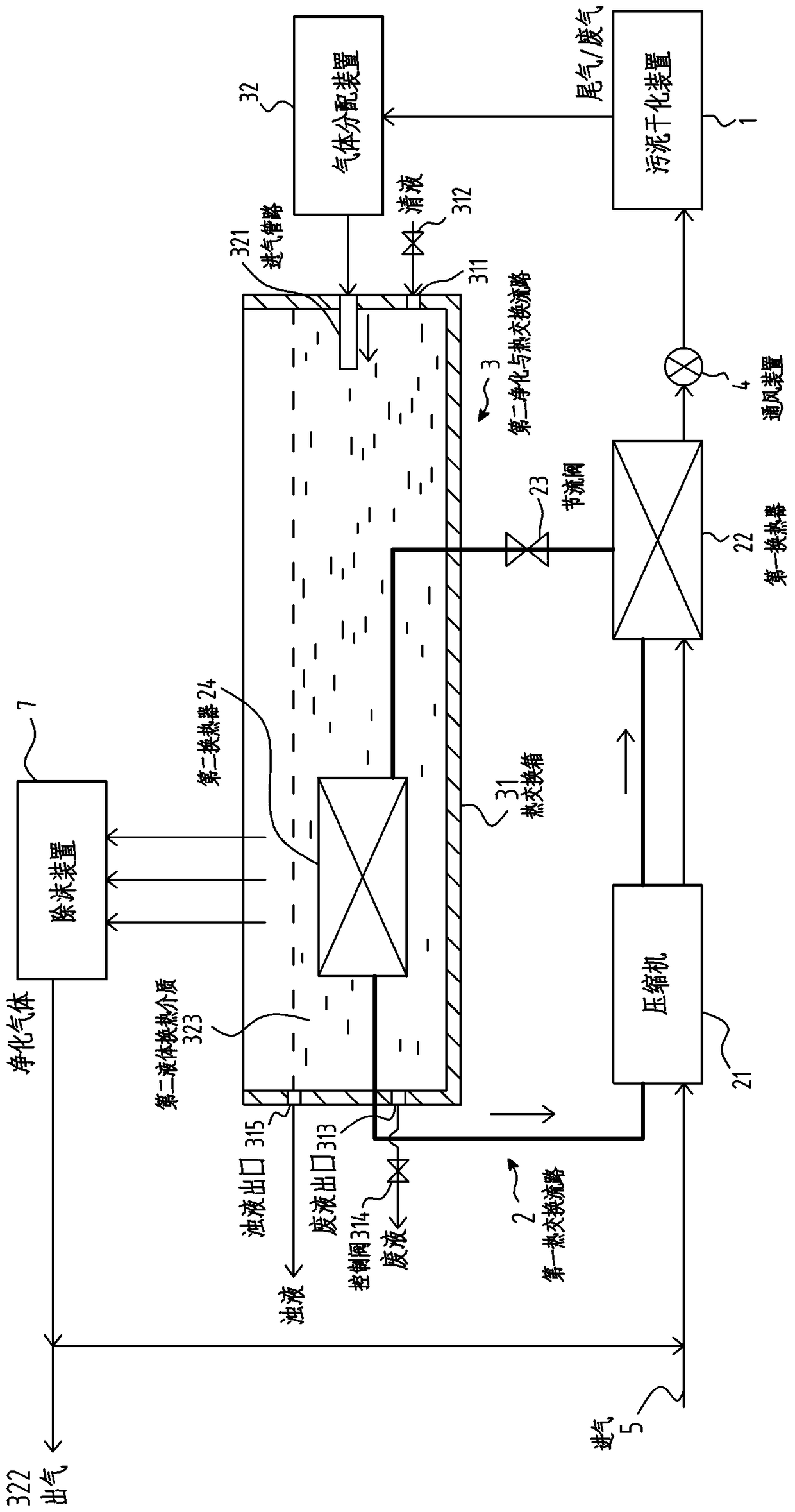

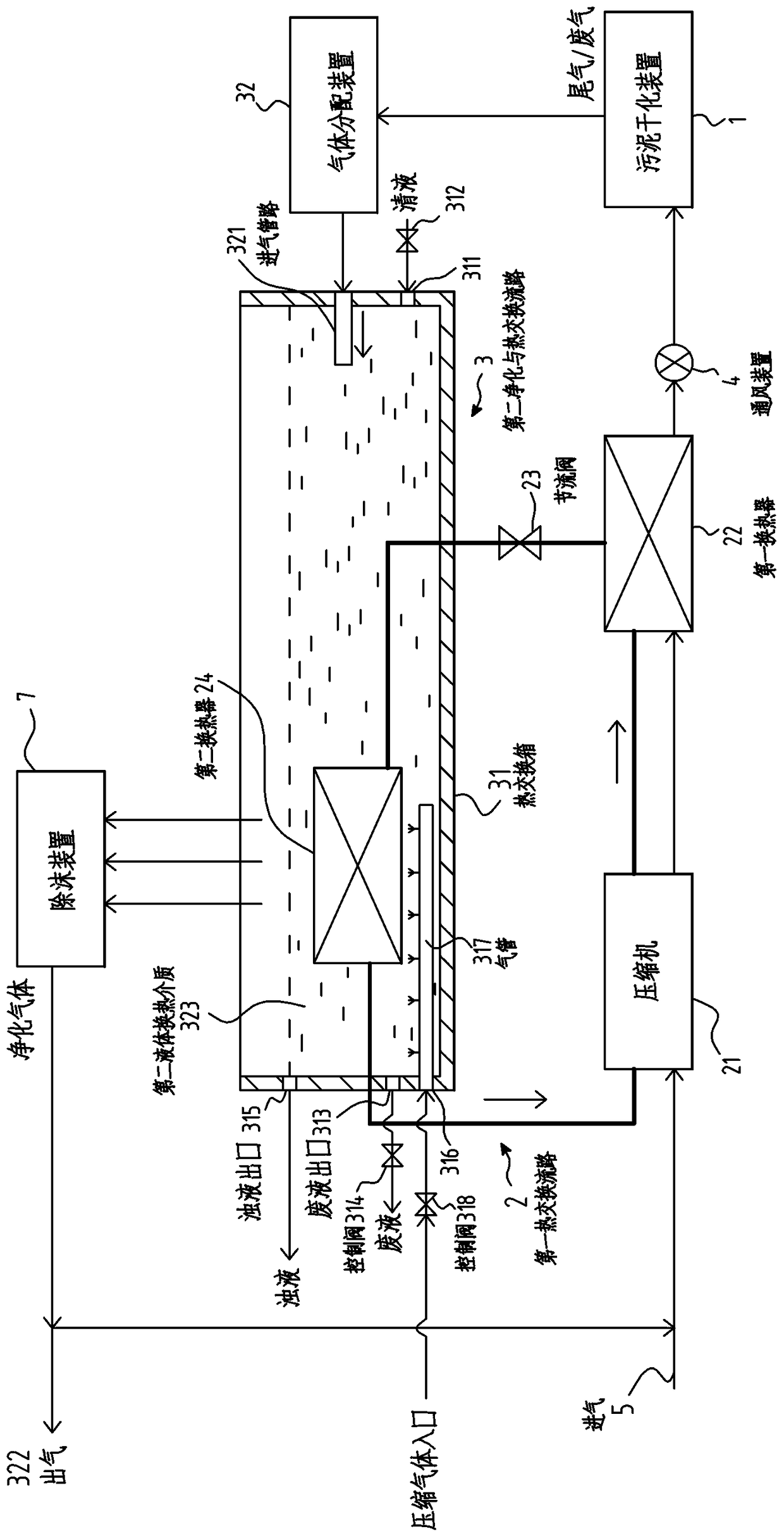

[0082] The following description is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses. With reference to the accompanying drawings, figure 1 is a schematic diagram of a preferred embodiment of the exhaust gas purification and heat recovery system according to the present invention. figure 2 is a schematic diagram of another preferred embodiment of the exhaust gas purification and heat recovery system according to the present invention. image 3 It is a schematic diagram of another preferred embodiment of the exhaust gas purification and heat recovery system according to the present invention. Figure 4 It is a schematic diagram of another preferred embodiment of the exhaust gas purification and heat recovery system according to the present invention. Figure 5 It is a schematic diagram of another preferred embodiment of the exhaust gas purification and heat recovery system according to the present invention.

[0083] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com