Belt type dehydrator and working method

A belt-type dehydration and dehydration machine technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of productivity impact and high energy consumption of equipment, and achieve significant reduction and pollution reduction. Effects of low mud moisture content and flexible disposal methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of this patent, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

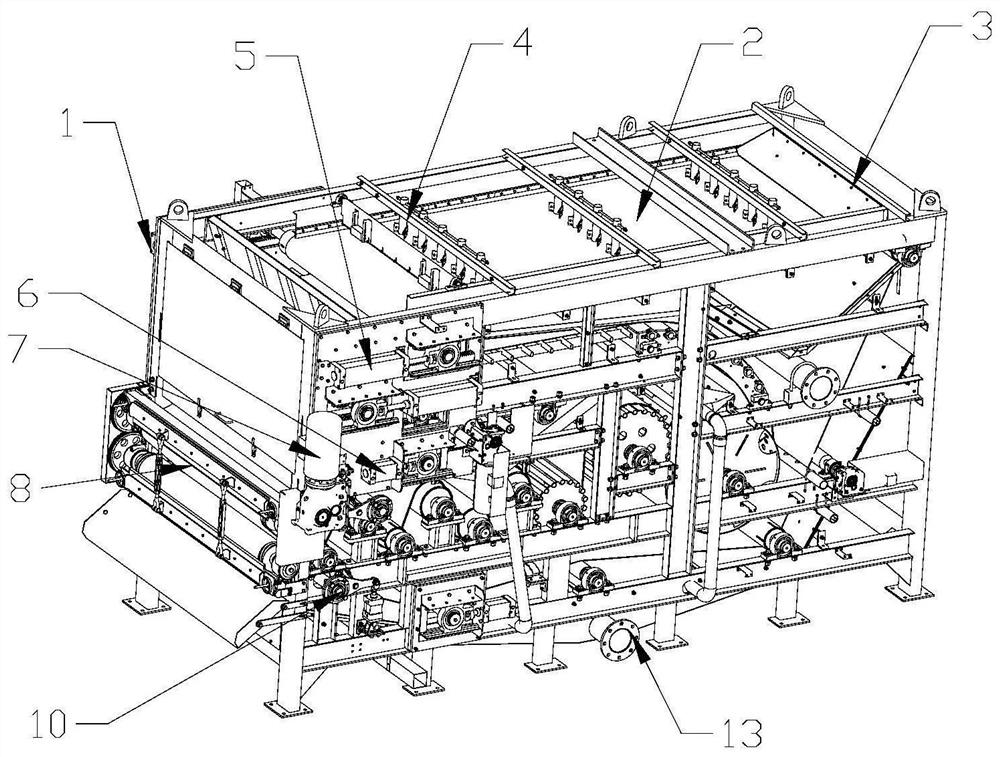

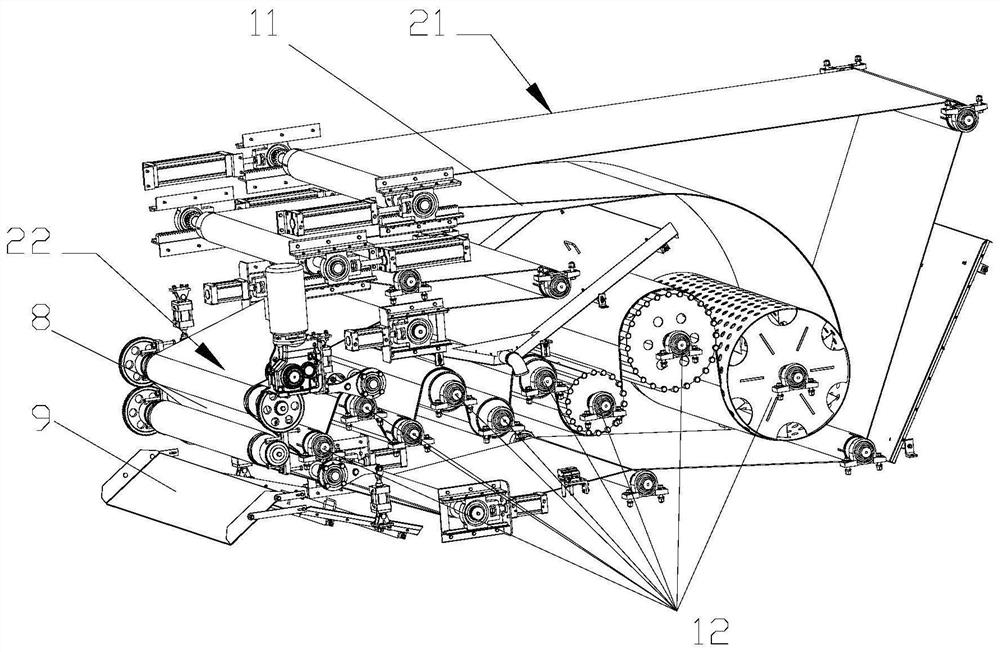

[0026] see Figure 1~3 , the invention discloses a belt dehydrator, comprising a dehydrator frame 1; a filter belt 2, a mud inlet 3, a gravity dehydration device 4, a tension mechanism 5, a deviation adjustment monitoring device, an adjustment Biasing device 6, motor reducer 7, mud strip separating device 8, mud outlet 9, wedge-shaped dehydration structure 11, S-shaped dehydration device 12, movable pressure device 10, drain port 13, and non-clogging cleaning device.

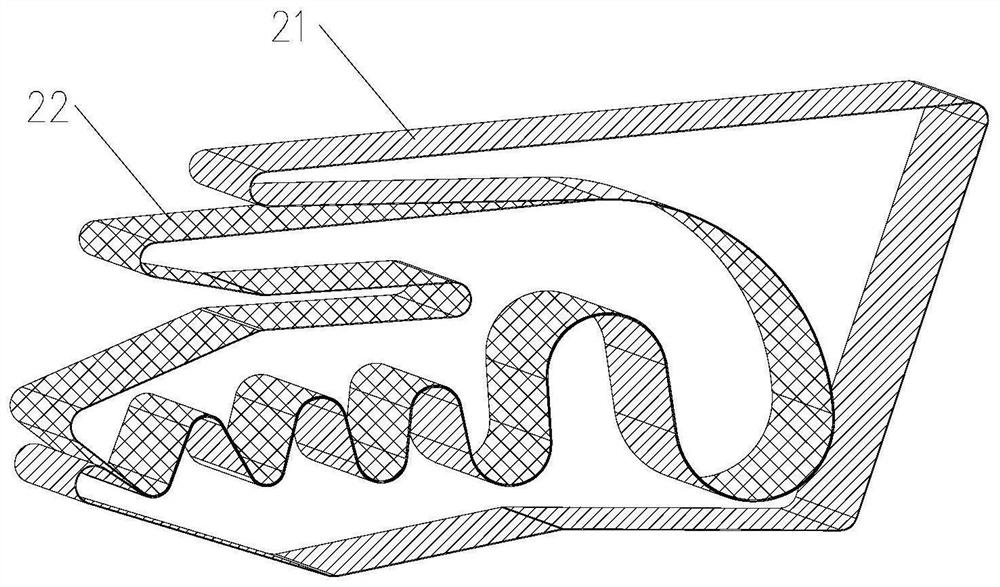

[0027] The filter belt 2 includes a filter belt 21 and a filter belt 22 connected with the mud inlet 3; the concentrated sludge moves forward with the filter belt 21 through the mud inlet 3 and falls onto the filter belt 2 22 ; In the inner side of filter belt one 21, filter belt one 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com