Method for preparing potassium hexatitanate lamellar crystal by using solid phase method

A technology of potassium hexatitanate and solid-phase method, which is applied in chemical instruments and methods, self-solid, single crystal growth, etc. It can solve the problems of large damage to the reaction container, increase the container, and cracking, so as to simplify the production process and improve the purity. and quality, the effect of avoiding industrial wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

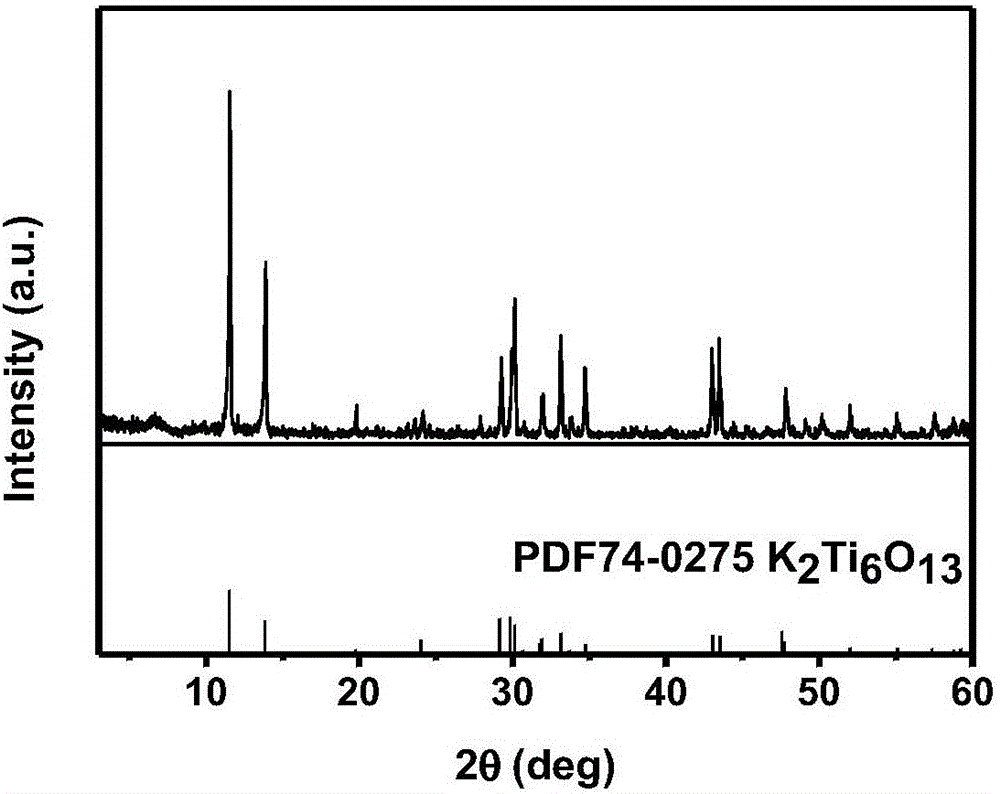

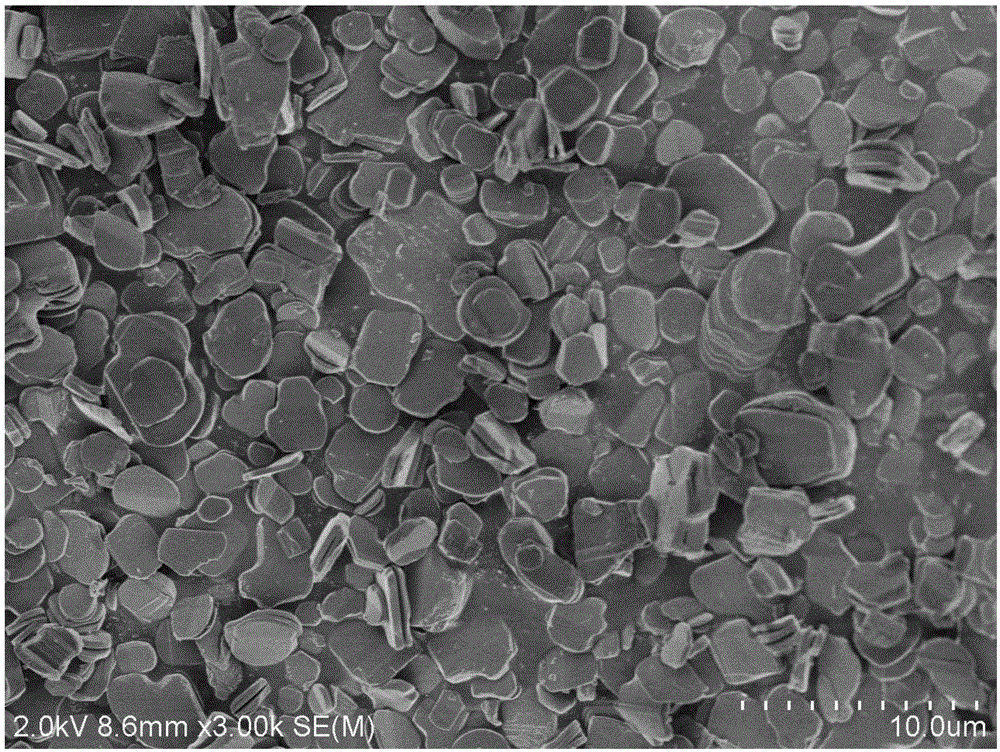

[0027] TiO 2 and K 2 CO 3 According to molar ratio TiO 2 :K 2 CO 3 = 2.1:1.0 ratio of uniform mixing, then add 3wt% crystal form inducer, place in a stirrer and mix evenly; then put the mixture in a muffle furnace for high-temperature calcination, the heating rate is 5°C / min, and the temperature is raised to 1000 ℃, keep warm for 2 hours, and cool with the furnace. The prepared potassium tetratitanate lamellae were broken, washed with boiling water, filtered or centrifuged, and then dried in an oven at 50° C. for 24 hours. The dried product was placed in a muffle furnace again, calcined at 800° C. for 3 h, and cooled with the furnace, thereby synthesizing potassium hexatitanate lamellae. The X-ray diffraction analysis shows that the chemical formula of the product obtained is K 2 Ti 6 o 13 , The scanning electron microscope observation shows that the potassium hexatitanate is in the form of flakes, and the measured platelet size of the potassium hexatitanate is: the a...

Embodiment 2

[0029] TiO 2 and K 2 CO 3 According to molar ratio TiO 2 :K 2 CO 3 = 3.8:0.8 ratio of uniform mixing, then add 5wt% crystal form inducer, put in a stirrer and mix evenly; then put the mixture in a muffle furnace for high-temperature calcination, the heating rate is 3 °C / min, and the temperature is raised to 1100 ℃, keep warm for 1 hour, and cool with the furnace. The prepared potassium tetratitanate lamellae were broken, washed with boiling water, filtered or centrifuged, and then dried in an oven at 60° C. for 15 hours. The dried product was placed in the muffle furnace again, calcined at 900° C. for 1 h, and cooled with the furnace, thereby synthesizing potassium hexatitanate lamellae. The X-ray diffraction analysis shows that the chemical formula of the product obtained is K 2 Ti 6 o 13 , The scanning electron microscope observation shows that the potassium hexatitanate is in the form of flakes, and the measured platelet size of the potassium hexatitanate is: the a...

Embodiment 3

[0031] TiO 2 and K 2 CO 3 According to molar ratio TiO 2 :K 2 CO 3 = 4.8:2.0 The ratio is evenly mixed, and then 5wt% crystal form inducer is added, placed in a stirrer and mixed evenly; then the mixture is placed in a muffle furnace for high-temperature calcination, the heating rate is 7 ° C / min, and the temperature is raised to 900 ℃, keep warm for 8 hours, and cool with the furnace. The prepared potassium tetratitanate lamellae were broken, washed with boiling water, filtered or centrifuged, and then dried in an oven at 70° C. for 8 hours. The dried product was placed in a muffle furnace again, calcined at 700° C. for 3 h, and cooled with the furnace, thereby synthesizing potassium hexatitanate lamellae. The X-ray diffraction analysis shows that the chemical formula of the product obtained is K 2 Ti 6 o 13 , The scanning electron microscope observation shows that the potassium hexatitanate is in the form of flakes, and the measured platelet size of the potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com