Framing machining method of core-shell structure door and window profiles

A door and window profile and core-shell structure technology, applied in the field of architectural decoration engineering, can solve the problems of joint deviation, easily damaged profile ends, uneven force application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

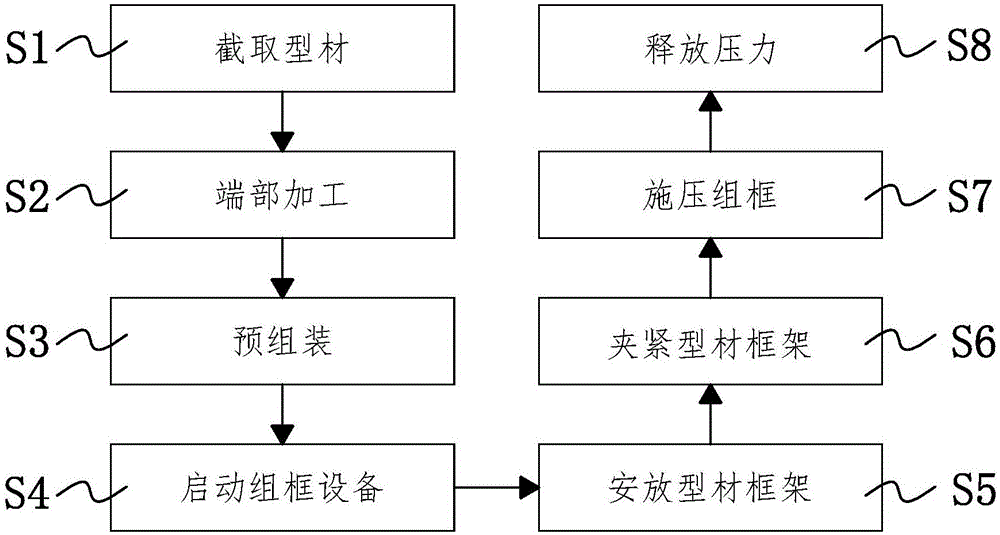

[0026] Specific Embodiment 1: Combining figure 1 with figure 2 Describe this embodiment mode, a kind of frame processing method for core-shell structure door and window profile described in this embodiment mode, comprises the following steps:

[0027] S1. Cutting profiles: Cutting the core-shell structure door and window profiles, taking two profiles with the same length as the longitudinal profiles, and taking two profiles with the same length as the horizontal profiles;

[0028] S2. End processing: Carry out end processing on the intercepted core-shell structure door and window profiles, so that the shell structures at both ends of the profile have a 45-degree angle slope, and make the core structure at the end of the profile have mortise and tenon joints that can be combined with each other;

[0029] S3. Pre-assembly: Pre-assemble the longitudinal and horizontal profiles after end processing, as well as the door and window inserts to obtain the door and window profile frame...

specific Embodiment approach 2

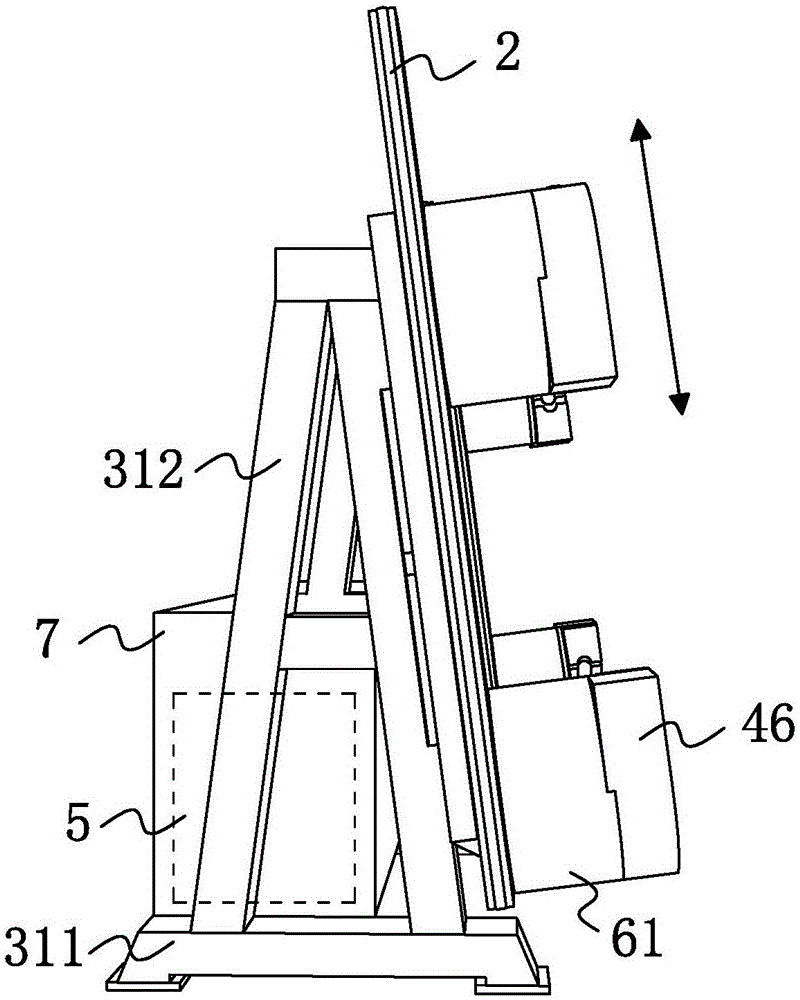

[0036] Specific Embodiment 2: Combining figure 1 , figure 2 with Figure 4 Describe this embodiment, a frame processing method for core-shell structure door and window profiles described in this embodiment, the longitudinal parallel rod 2 in step S5 has a longitudinal hydraulic guide rail 23; start the longitudinal hydraulic guide rail in step S6 23 According to the size of the door and window profile frame obtained by pre-assembly, properly adjust the relative positional relationship of the corner end table 4 on the longitudinal parallel bar 2; The first table 41 and the second table 42 that are movably arranged on the solid rod 21; The fourth platform 44 on the bar 22; the second platform 42 and the fourth platform 44 are respectively connected to the longitudinal hydraulic guide rail 23; in step S7, the longitudinal hydraulic guide rail 23 is started, so that the second platform 42 and the fourth platform Four sets 44 move along the longitudinal parallel bar 2 toward th...

specific Embodiment approach 3

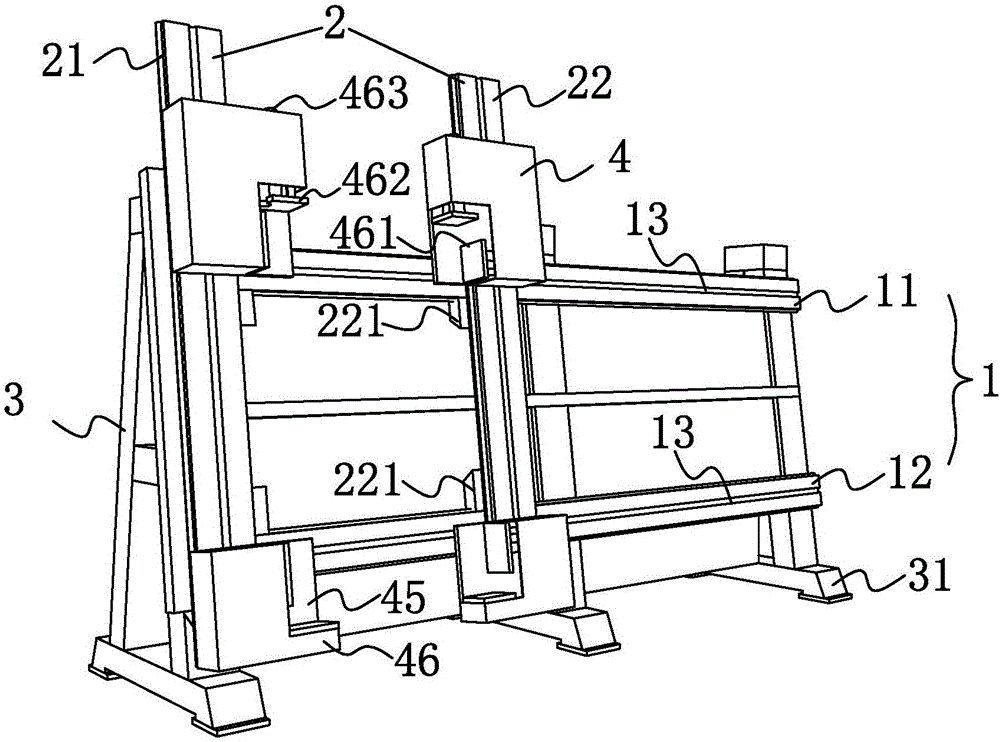

[0038] Embodiment 3: Combining figure 1 , figure 2 , image 3 with Figure 4 Describe this embodiment, a kind of framing processing method for core-shell structure door and window profiles described in this embodiment, the framing equipment described in step S4 has at least one set of horizontal parallel bars 1 and a set of longitudinal bars 1 in a perpendicular relationship with it. Parallel bar 2, described transverse parallel bar 1 is fixed on the support foot 31, and described support foot 31 is arranged in parallel and constitutes rigid support 3, and described transverse parallel bar 1 is divided into upper bar 11 and lower bar 12, and described longitudinal The parallel rod 2 is divided into a fixed rod 21 and a moving rod 22. The fixed rod 21 is located at one end of the horizontal parallel rod 1 and its relative position with the horizontal parallel rod 1 is fixed. The upper rod 11 and the lower rod 12 has a hydraulic transmission slide rail 13, and the moving rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com