A model predictive torque control method for five-phase permanent magnet synchronous motor

A permanent magnet synchronous motor, model prediction technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the large calculation burden of the digital control system, large harmonics of the motor stator current, and poor control effect etc. to achieve the effects of simplifying the input control set, fast dynamic response, and avoiding redundant calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

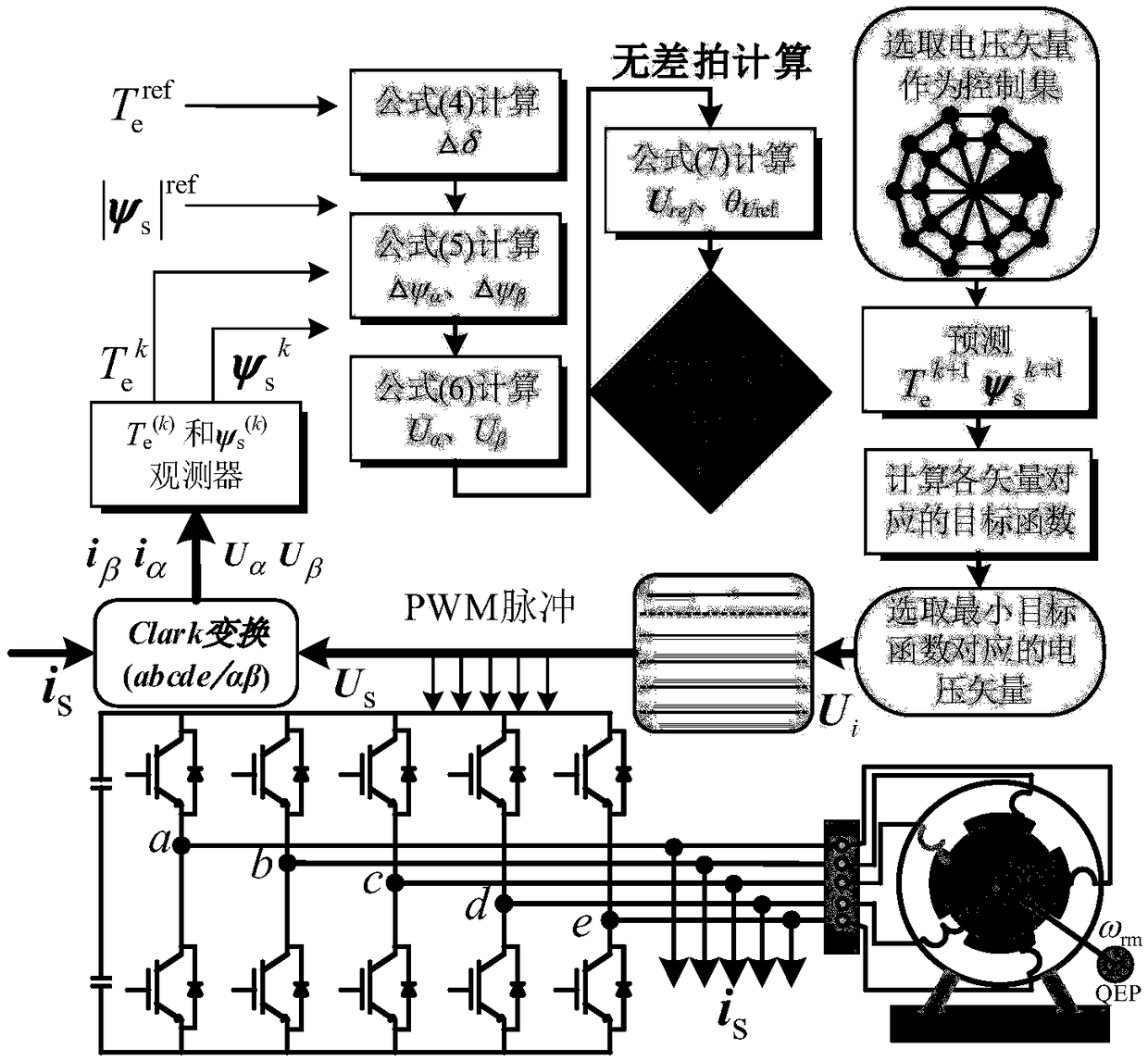

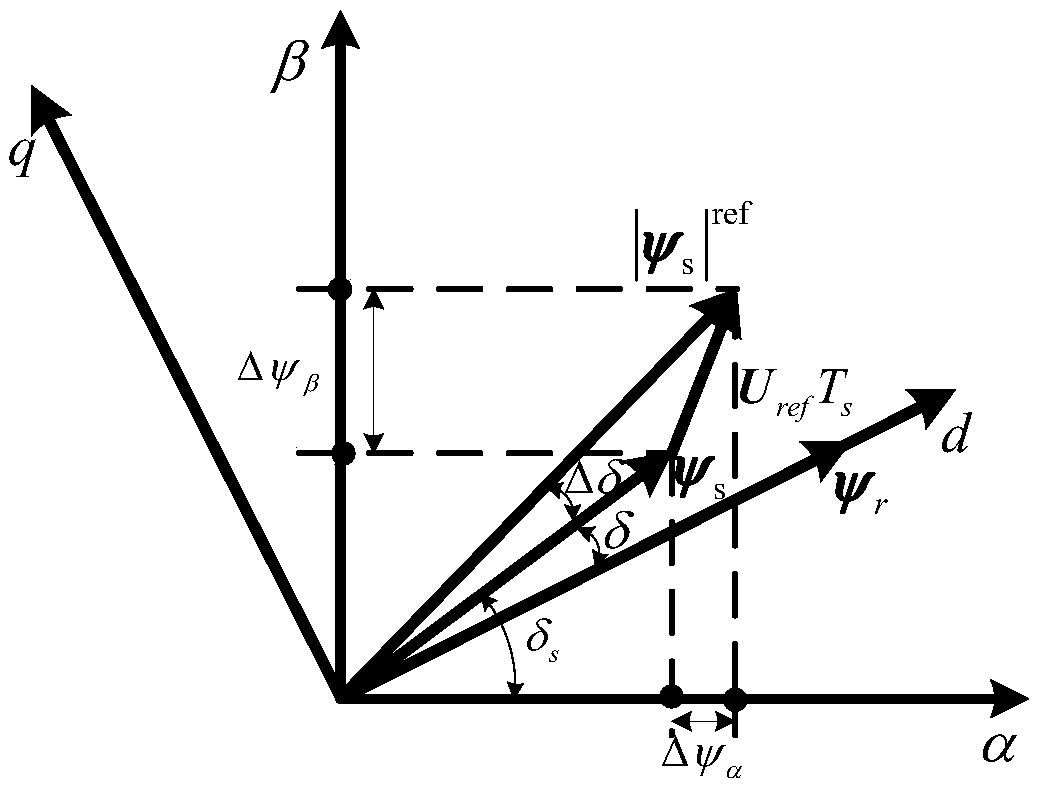

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The method of the invention significantly reduces the amount of calculation, also realizes the predictive control of the torque, and improves the dynamic response capability of the system. Specifically include the following steps:

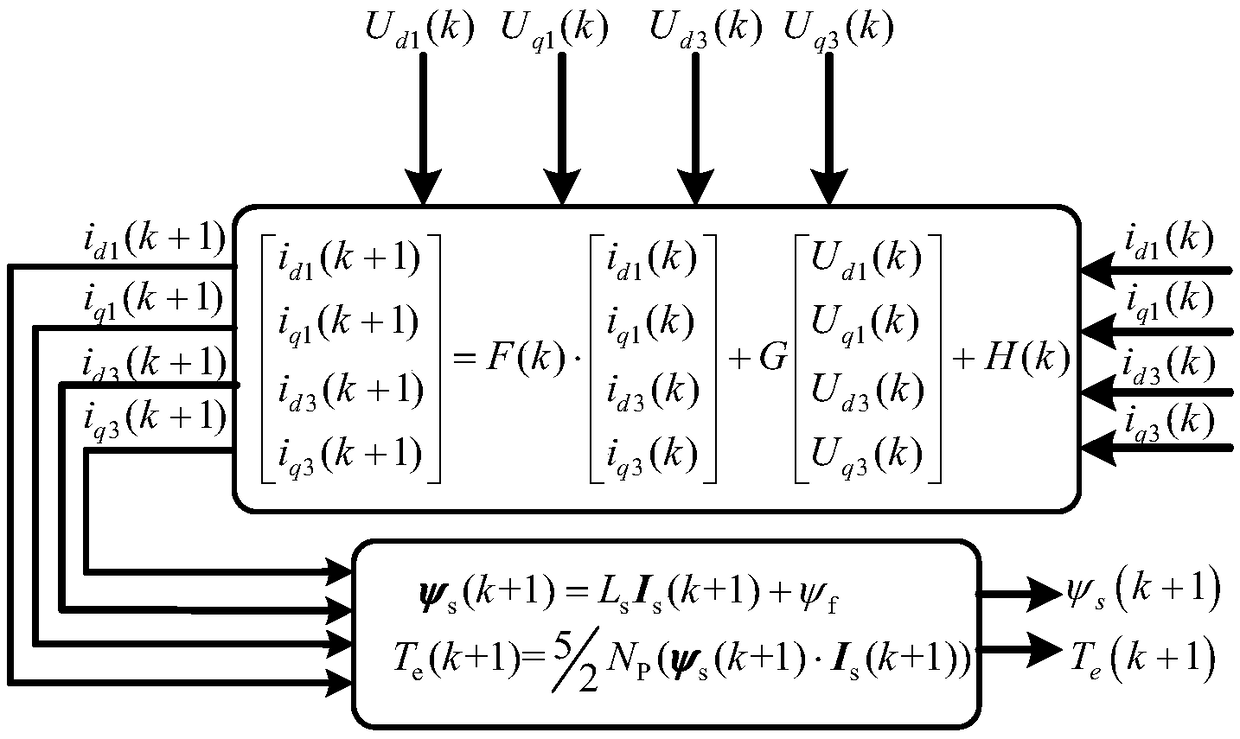

[0045] The five-phase motor system contains four degrees of freedom and zero-sequence components. In the normal running state of the motor, the symmetrical physical quantities in the natural coordinate system are mapped to the two orthogonal coordinate systems of d1-q1 and d3-q3 according to the extended Parker rotation transformation formula. Classify the space vectors of two-level five-phase voltage source inverters (Table 1), and calculate the magnitudes of various voltage vectors according to formula (1).

[0046] Table 1 Classification of voltage vector groups

[0047]

[0048]

[0049] In form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com