Hydrotreating catalyst impregnating solution and preparation method thereof

A technology of impregnation solution and hydrotreating, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high initial active metal content and difficult to achieve, and achieve moderate force , The effect of stable properties and high metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

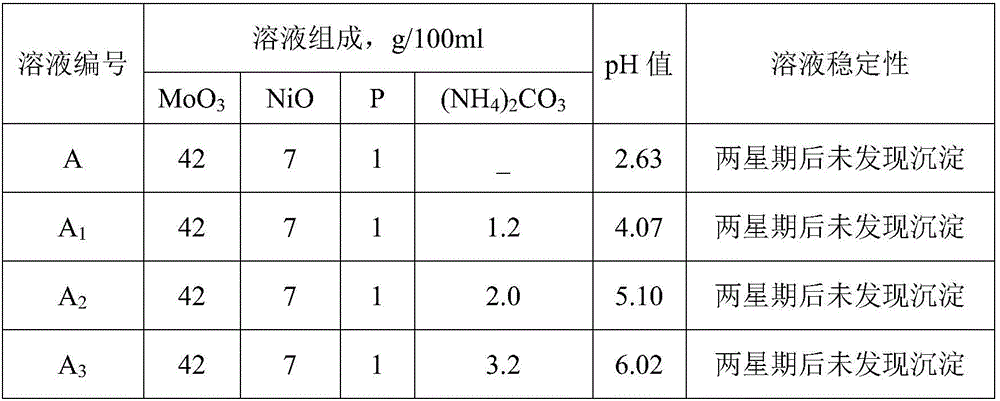

Embodiment 1

[0025] This example introduces the method of adding ammonium carbonate to adjust the pH of the solution to about 4 during the preparation of the Mo-Ni-P impregnating solution. Get 9.3g phosphoric acid (mass concentration 85.0%) and 150ml water and mix and add there-necked flask, add molybdenum trioxide (industrial grade) 105.1g and basic nickel carbonate (in terms of Ni, 44.0% by weight) 29.4g in stirring, be warming up to 40~50℃, react for 0.5h, slowly add 3.0g of ammonium carbonate (as NH 3 40.0% by weight), heated up to 90-100°C, reacted for 1h, stopped heating, cooled to room temperature, filtered the resulting solution, and settled the volume to 250ml to obtain dark green clear and transparent solution A 1 . The pH of the solution was measured to be 4.07.

Embodiment 2

[0027] This example introduces the method of adding ammonium carbonate to adjust the pH of the solution to about 5 during the preparation of the Mo-Ni-P impregnating solution. Get 9.3g phosphoric acid (mass concentration 85.0%) and 150ml water and mix and add there-necked flask, add molybdenum trioxide (industrial grade) 105.1g and basic nickel carbonate (in terms of Ni, 44.0% by weight) 29.4g in stirring, be warming up to 40~50℃, react for 0.5h, slowly add 5.1g of ammonium carbonate (as NH 3 40.0% by weight), heated up to 90-100°C, reacted for 1h, stopped heating, cooled to room temperature, filtered the resulting solution, and settled the volume to 250ml to obtain dark green clear and transparent solution A 2 . The pH of the solution was measured to be 5.10.

Embodiment 3

[0029] This example introduces the method of adding ammonium carbonate to adjust the pH of the solution to about 6 during the preparation of the Mo-Ni-P impregnating solution. Get 9.3g phosphoric acid (mass concentration 85.0%) and 150ml water and mix and add there-necked flask, add molybdenum trioxide (industrial grade) 105.1g and basic nickel carbonate (in terms of Ni, 44.0% by weight) 29.4g in stirring, be warming up to 40~50℃, react for 0.5h, slowly add 8.0g of ammonium carbonate (as NH 3 40.0% by weight), heated up to 90-100°C, reacted for 1h, stopped heating, cooled to room temperature, filtered the resulting solution, and settled the volume to 250ml to obtain dark green clear and transparent solution A 3 . The pH of the solution was measured to be 6.02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com