A steel plate reel device

A technology of steel plate coils and vertical plates, which is applied in the field of processing equipment, can solve the problems of arm stuck into the seam of the steel cylinder, potential safety hazards, difficult operation and increased labor intensity, and achieve low labor intensity, high reliability and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

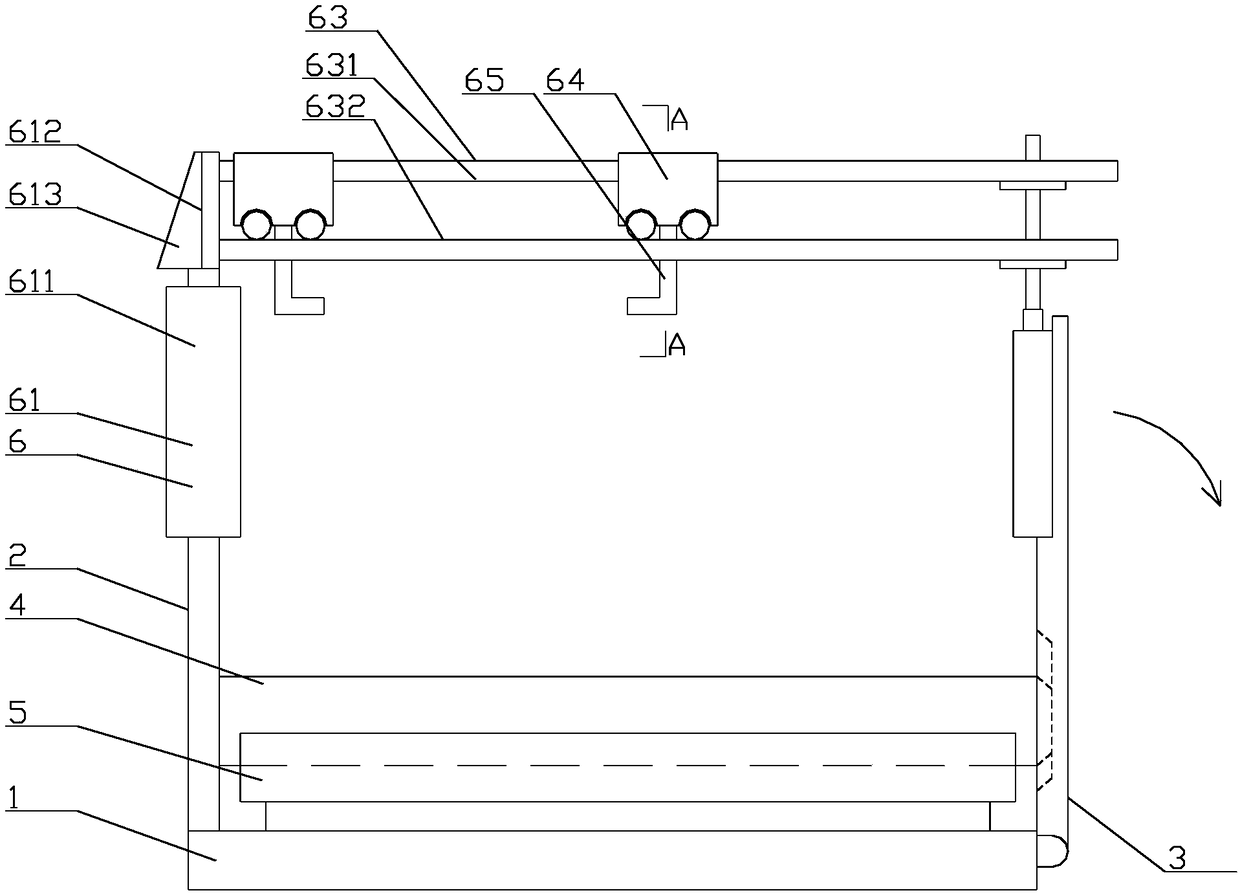

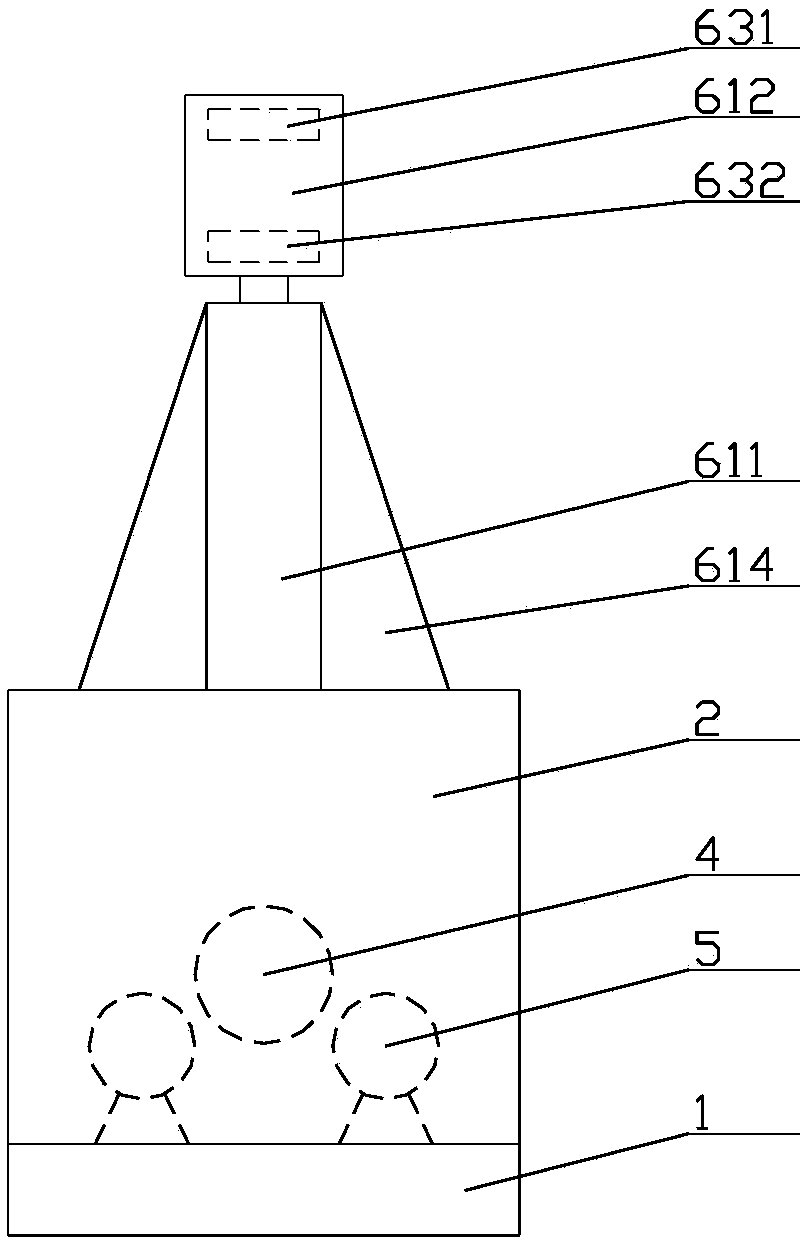

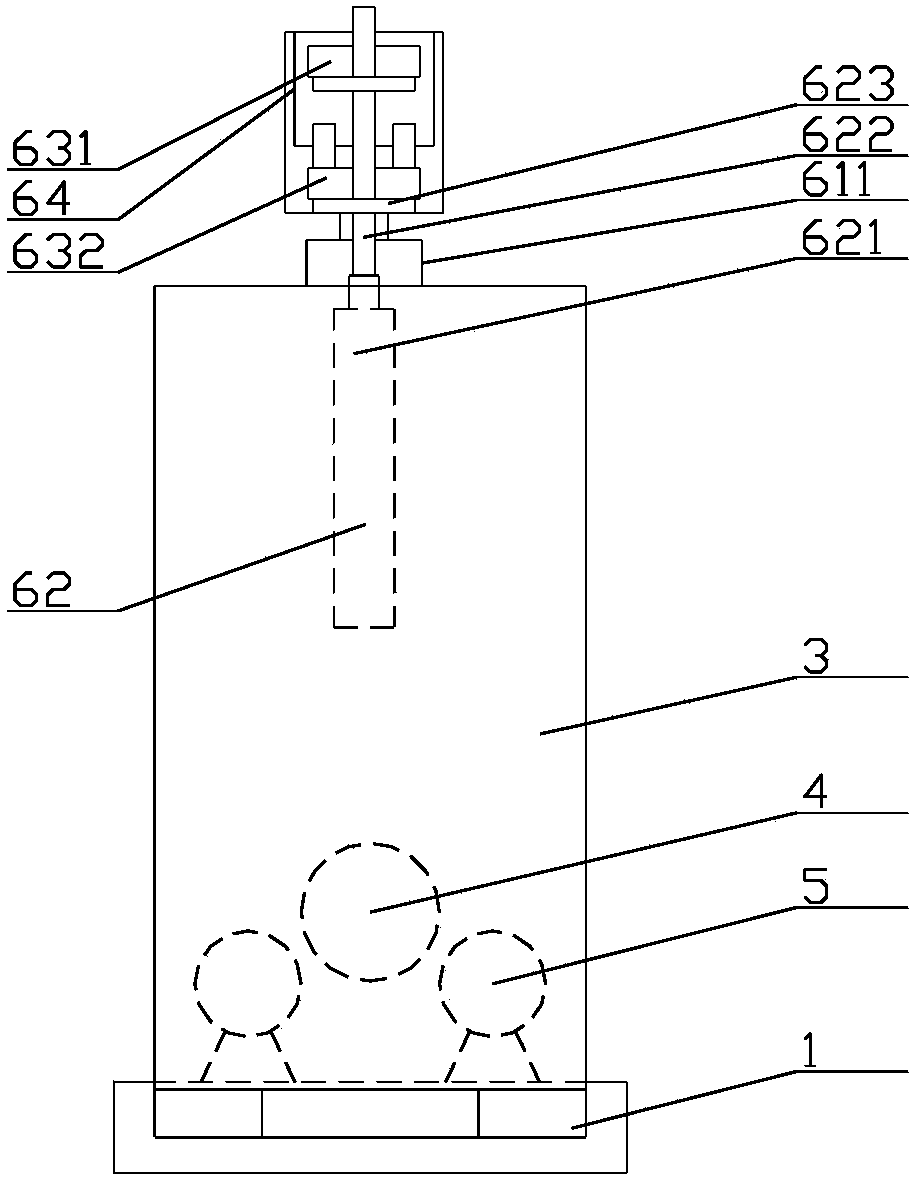

[0028] The present invention as Figure 1-7 As shown, it includes a bottom plate 1, a fixed vertical plate 2, a movable vertical plate 3, a main pressure roller 4, a pair of auxiliary pressure rollers 5 and a lifting assembly 6, and the fixed vertical plate 2 is vertically arranged and fixedly connected to the bottom plate 1. One side, one side of the movable vertical plate 3 is hinged with the side of the bottom plate 1 away from the fixed vertical plate 2, a pair of the secondary pressure rollers 5 are hinged above the bottom plate 1 through a bracket, and the main pressure roller 4 is hinged On the fixed vertical plate 2 and arranged above the auxiliary pressure roller 5, the main pressure roller 4 and the auxiliary pressure roller 5 are all horizontally arranged and parallel to each other; when in use, the movable vertical plate can be turned up to a vertical state, Then open the main pressure roller, so that the steel plate travels between the main pressure roller and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com