Core rod graphite lubricant

A technology of graphite lubricants and lubricants, applied in the direction of lubricating compositions, petroleum industry, base materials, etc., can solve the damage, sometimes it is necessary to replace the clamping head once a week, affecting the surface quality of steel pipes, mandrel surface damage, etc. problem, achieve the effect of improving the mandrel lubrication effect, prolonging the equipment replacement cycle, and improving the quality of the inner surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The manufacturing process of the mandrel graphite lubricant of the present invention is described in conjunction with the examples.

[0019] Through the analysis and study of the characteristics of high alloy steel, the causes of problems in the steel pipe rolling process, combined with the characteristics of the original graphite lubricant, in order to ensure that the mandrel graphite lubricant achieves good film-forming performance and high temperature adhesion, the mandrel graphite Lubricant, this lubricant is by weight, and its composition is as follows:

[0020] Graphite: 50%-60%, particle size 200-300 mesh;

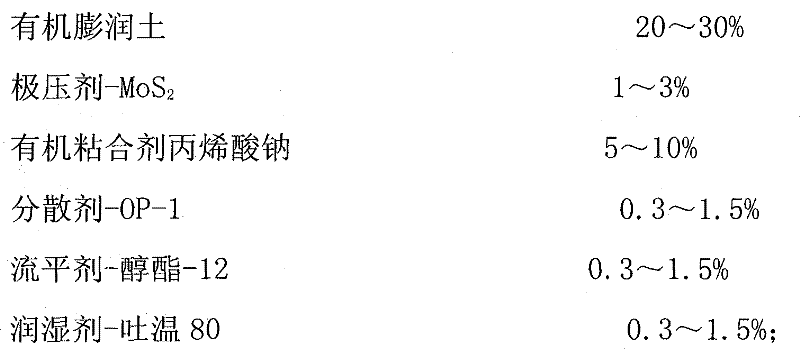

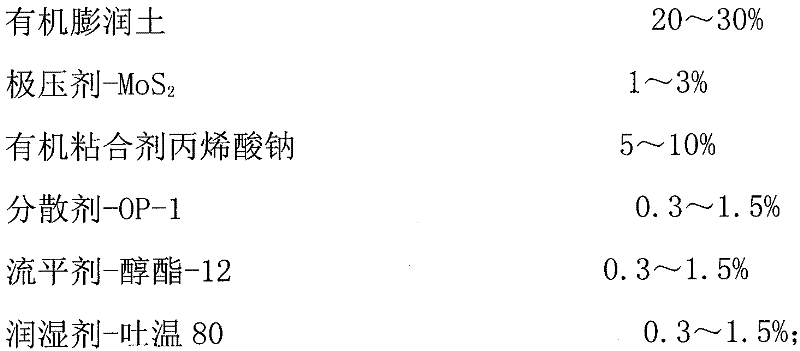

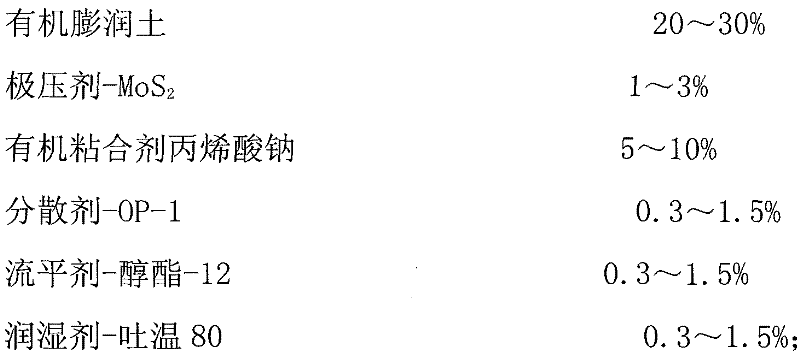

[0021] Composite Adhesive Type B - COB-B:

[0022]

[0023] Auxiliary additives:

[0024] Thickener-CMC cellulose 1~3%

[0025] Defoamer-tributyl phosphate 0.3~3%

[0026] Preservatives - sodium benzoate 0.2 to 2%.

[0027] The mandrel graphite lubricant of the present invention is realized in this way.

[0028] 1. Selection of adhesive:

[0029] Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com