Plastic vibration processing and sample molding integration test equipment and method

A technology for vibration processing and testing equipment, which is applied in the field of integrated testing equipment for plastic vibration processing and sample molding, to achieve the effects of saving experimental costs and time, facilitating implementation, and recording and analyzing data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

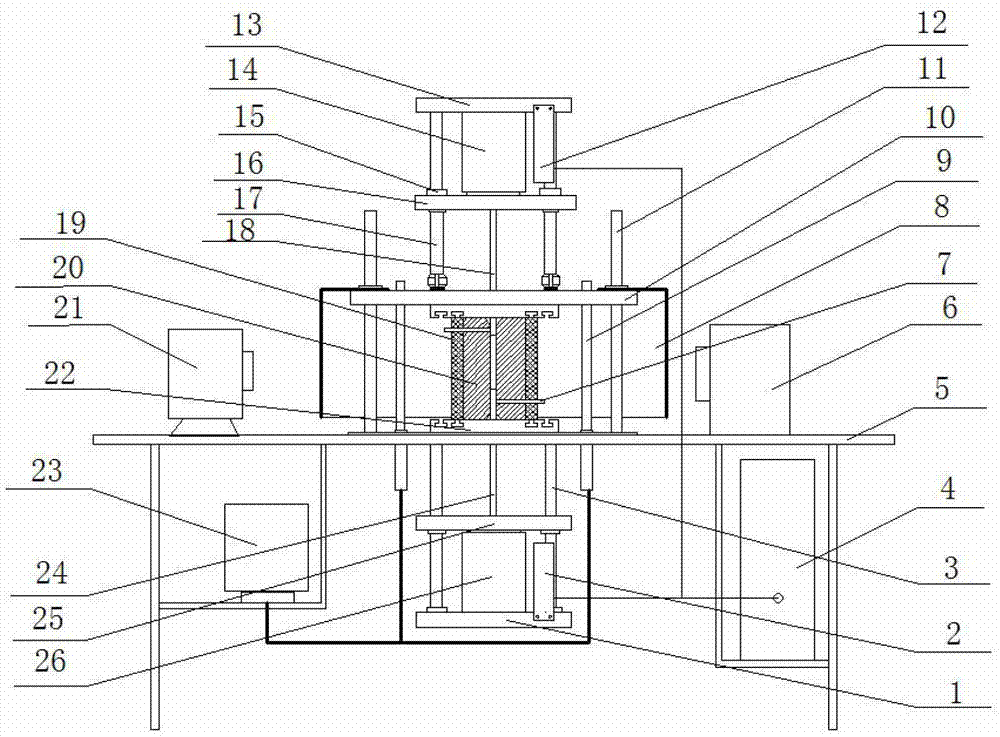

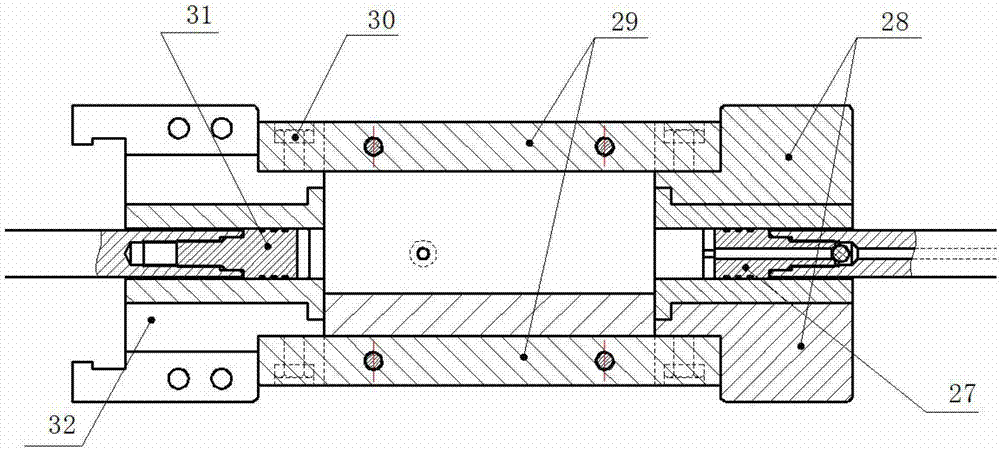

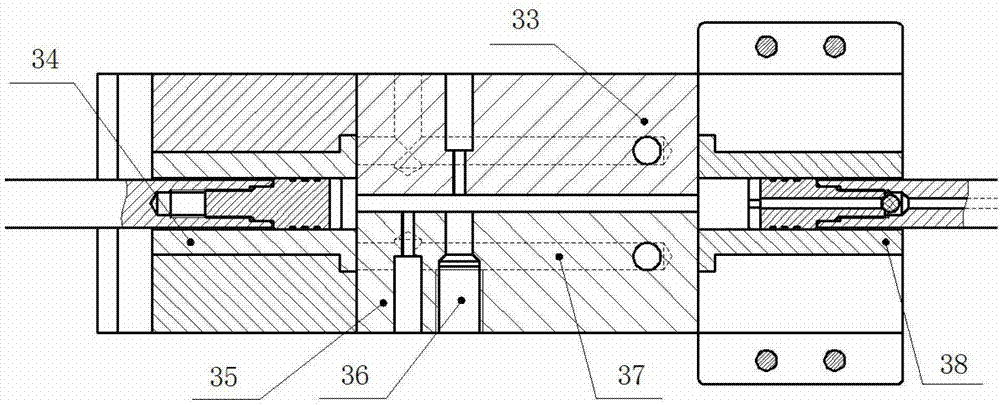

[0026] The principle of the present invention is: combine vibration and other field effects with direct sample forming, apply high-frequency vibration and high pressure to the experimental materials, and directly obtain and detect mixed samples through an independent central mold structure, and at the same time, it is equipped with online data collection and analysis. monitoring function. By selecting or designing different flow channel structures of the central mold to conduct mixed shape experiments; selecting or designing the central mold with capillary structure can conduct dynamic rheological experiments; selecting or designing the open central mold can directly obtain microstructure samples. Through the use of central molds of different forms and structures and the adjustment of various parameters related to multiple external fields, the detection of plastic processing morphology, microstructure and rheological properties under the action of vibration induction is realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com