Integrated management aquaculture engineering ship

A technology for engineering ships and hulls, applied to hulls, fish farming, shipbuilding, etc., to achieve the effects of improving stability, reducing free liquid surface, and increasing hull strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

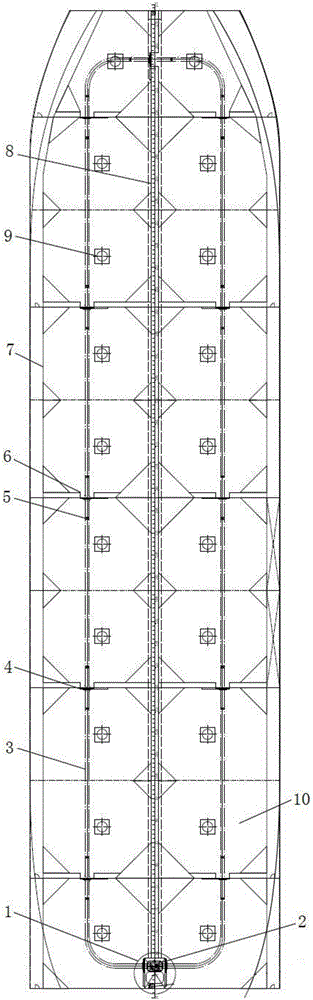

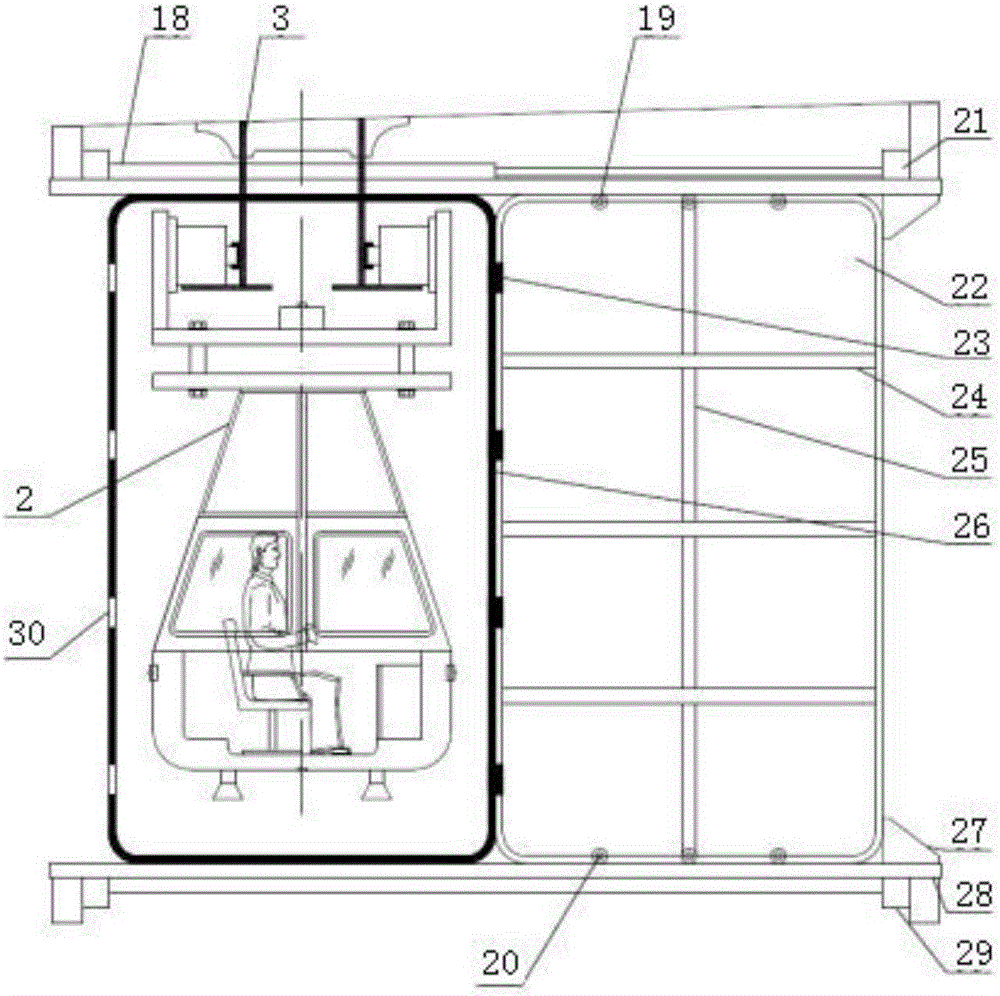

[0040] Such as figure 1 As shown, the breeding engineering ship of integrated management includes a hull, a fish tank 10, a mobile platform transfer station 1, a mobile platform 2 and an annular track 3 arranged around the top of the fish tank 10; the mobile platform 2 Connect the circular track 3 and move along the circular track 3, the height of the lowest point of the mobile platform 2 is higher than the water level line of the fish tank 10; the transfer station 1 of the mobile platform is arranged under the circular track 3, and the mobile platform The top height of the transfer station 1 is lower than the bottom of the mobile platform 2; the hull is provided with a watertight transverse bulkhead 6, and the fish farming tank 10 is divided into a plurality of compartments by the watertight transverse bulkhead 6, and the watertight transverse bulkhead The bulkhead 6 is provided with an automatic watertight door 4 for the mobile platform 2 to pass through;

Embodiment 2

[0042] This embodiment is on the basis of embodiment 1:

[0043] Such as figure 1 As shown, the hull is also provided with a middle longitudinal bulkhead 9, and the fish farming tank 10 is divided into a plurality of compartments by the watertight transverse bulkhead 6 and the middle longitudinal bulkhead 9, and the middle longitudinal bulkhead 9 is divided into a plurality of compartments. The bulkhead 9 is provided with an automatic watertight door for the mobile platform to pass through; the circular track is disconnected at the automatic watertight door, and the distance between the disconnections is greater than the thickness of the automatic watertight door.

Embodiment 3

[0045] This embodiment is on the basis of embodiment 1:

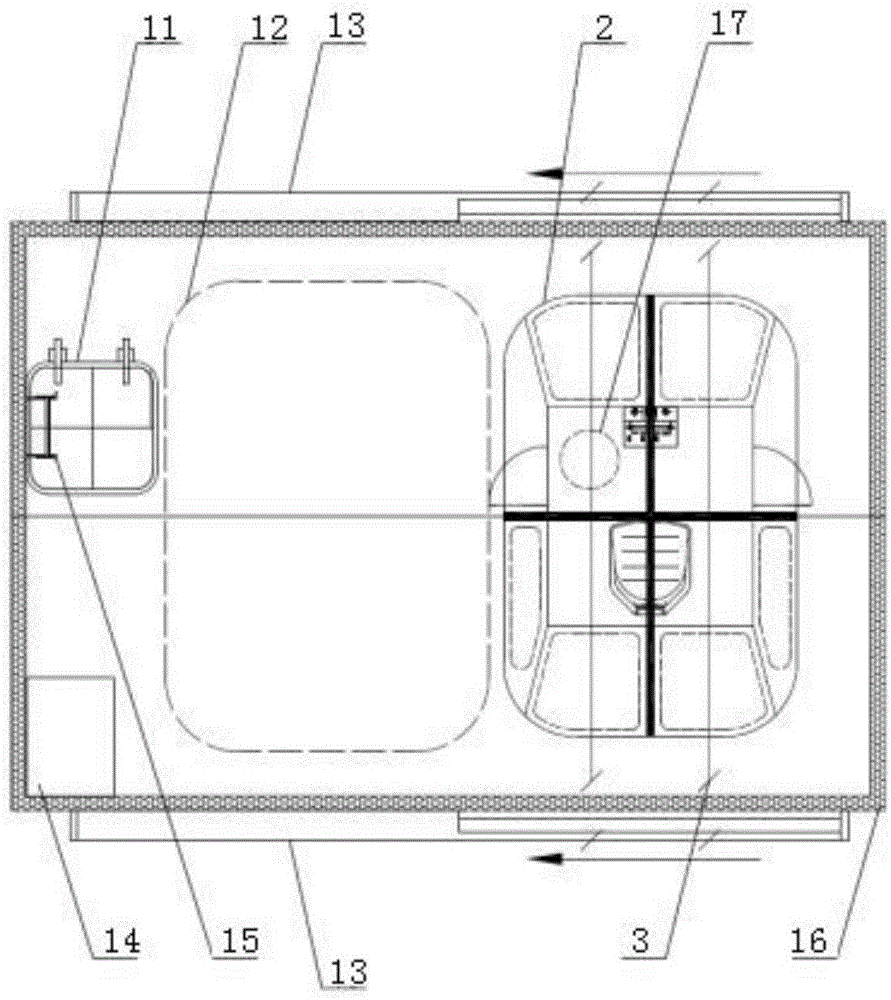

[0046] Such as figure 2 As shown, the mobile platform transfer station 1 is surrounded by watertight steel, and its top is provided with a mobile platform inspection hole 12, a charging device 14 and a manhole 11 for personnel to enter and exit, and its top two sides are respectively provided with a mobile platform. The automatic watertight door 13 that enters and exits, and the annular track 3 is disconnected at the automatic watertight door, and the spacing of its disconnection is greater than the thickness of the automatic watertight door.

[0047] Said manhole 11 for personnel access is provided with a marine ladder 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com