A method for improving the efficiency of sulfonation reaction and the production method of dispersant mf

A production method and dispersant technology, applied in chemical instruments and methods, preparation of organic compounds, formation/introduction of sulfonic acid groups/dihydroxysulfonyl groups, etc., can solve problems such as residues, explosion hazards, large additives, etc., to achieve Contribute to environmental protection, reduce burden and cost, and reduce the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

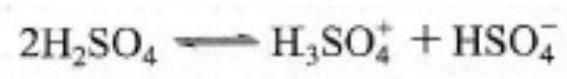

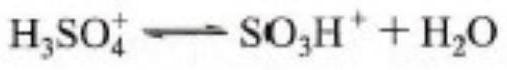

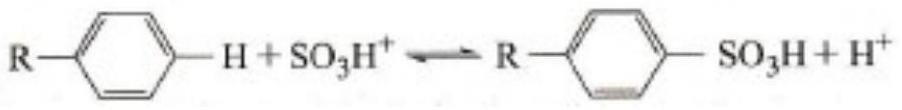

Method used

Image

Examples

Embodiment 1

[0041]The raw material was raised to 100 ° C with 3000 kg of wash oil (methyl naphthalene and naphthalene), and the pump was raised to 100 ° C, and the pump was pumped into the reactor, and the temperature was 105 ° C, and the reaction was 0.5 h, the vacuum, the vacuum is 456mmHg, the water belt in the sulfonation process is used to maintain a vacuum reaction for 2 h, and the regulatory vacuum is 152 mmHg. The reaction system is introduced into nitrogen, and the subsequent vacuum is difficult to bring out by nitrogen. , The flow rate of nitrogen is 4m3 / h, the time in which nitrogen is introduced is 4 h, and the sulfonation reaction is completed.

[0042]After the sulfonation reaction, the acidity was cooled to 100 ° C, and the acid was adjusted to 14.6%, and the formaldehyde was 920 kg, and the temperature was 120 ° C, the pressure was 0.2 MPa, and the reaction was 4 h.

[0043]The resulting condensation material was adjacent to 7.2 by 30%, and the MF slurry was dried to dry the MF produ...

Embodiment 2

[0045]With 3000 kg of methyl naphthalene as raw materials, 1050 kg, 98% sulfuric acid were raised to the reactor with a pump, and the temperature was 10.5 h, the vacuum was 456 mmHg, and the sulfonation process was generated. The water belt out of the system, maintains a vacuum reaction for 2 h, the regulatory vacuum is 152 mmHg, the reaction system is introduced into nitrogen, and the water that is difficult to bring out of the subsequent vacuum to the water, and the flow rate of nitrogen is 4m.3 / h, the time in which nitrogen is introduced is 4 h, and the sulfonation reaction is completed.

[0046]After the sulfonation reaction, the acidity was cooled to 100 ° C, and the acid was adjusted to 15.3%, add formaldehyde 920 kg, and the temperature was allowed to maintain 100 ° C, atmospheric pressure, reaction for 6 h.

[0047]The resulting condensation material was adjacent to 7.0 by 30%, and the MF slurry was obtained, and the MF product was dried. The product had a sodium sulfate content ...

Embodiment 3

[0049]With 2000kg naphthalene as raw material, 10,000 kg, 98% sulfuric acid was raised to 100 ° C, and the pump was pumped into the reactor, and the temperature was raised to 155 ° C, the reaction was 0.5h, the vacuum was 456 mmHg, and the water generated by the sulfonation process With the system, maintain a vacuum reaction for 2 h, the regulated vacuum is 152 mmHg, the reaction system is introduced into nitrogen, and the flow rate of the subsequent vacuum is difficult to bring out by nitrogen, and the flow rate of nitrogen is 4m.3 / h, the time in which nitrogen is introduced is 4 h, and the sulfonation reaction is completed.

[0050]After the sulfonation reaction, the temperature dropped to 80 ° C for 30% liquid base tuning pH of 7.0, and the precipitation of naphthalenesulfonate was precipitated, and the salt content was 3.6% in wastewater, compared to conventional process wastewater. The salt content is reduced by more than 80%. At the same time, the amount of sulfuric acid is also...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap