Combination Confined Double Steel Plate Concrete Shear Wall and Its Construction Method

A technology of concrete shear wall and double steel plate, applied in the direction of walls, buildings, building components, etc., can solve the problems of poor ductility of high-strength concrete, restraint effect of high-strength concrete, restricting the application of double-steel plate high-strength concrete shear wall, etc. Buckling, Effects of Increased Bearing Capacity and Deformation Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

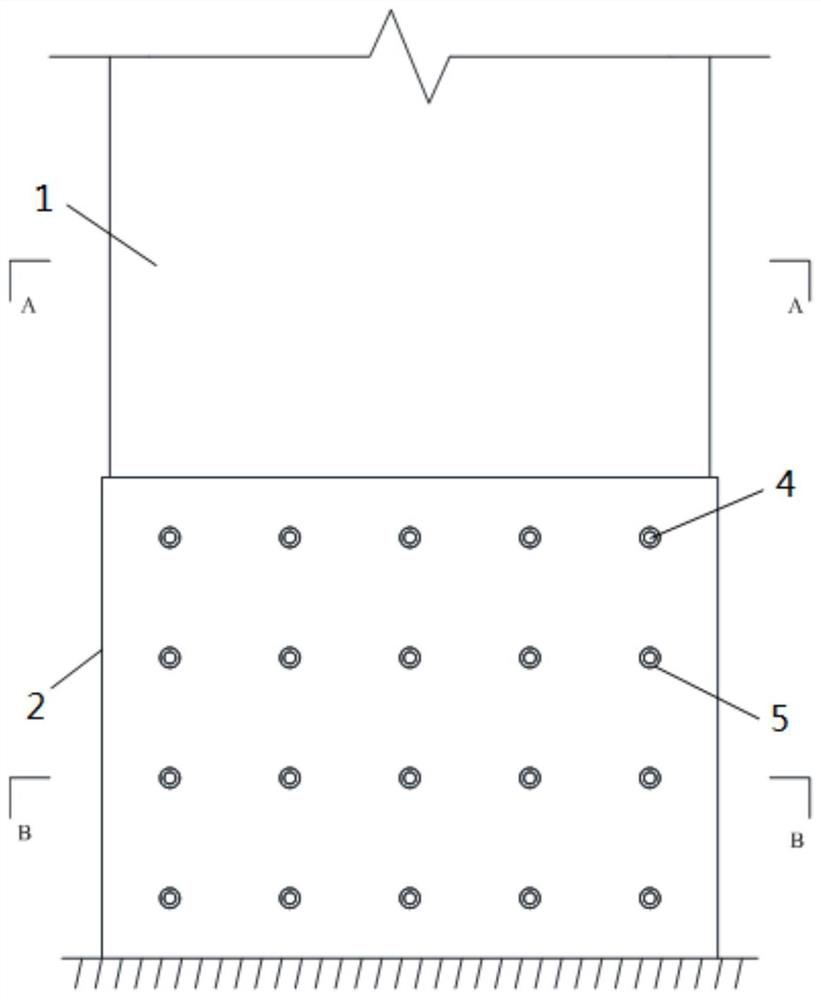

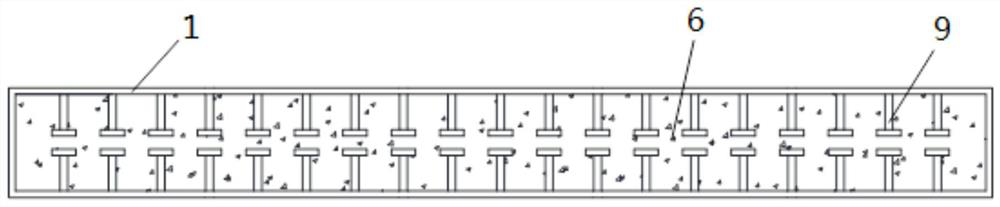

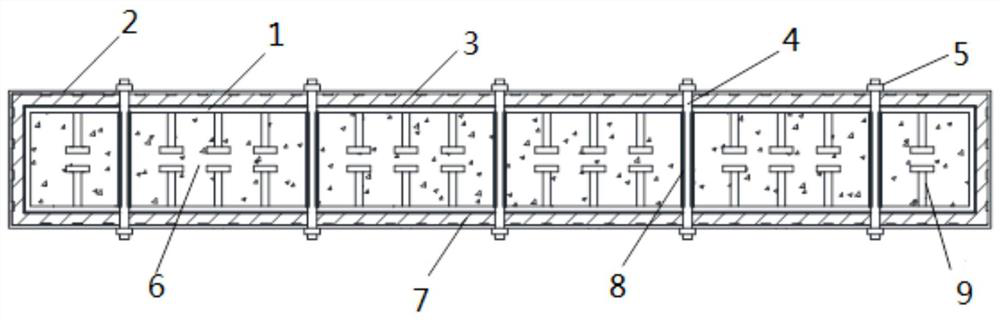

[0025] A composite constrained double steel plate concrete shear wall is composed of a load-bearing steel plate 1, a constrained steel plate 2, an unbonded material 3, a tension screw 4, a nut 5, concrete 6, a self-leveling mortar 7, a rubber sleeve 8, and a stud 9. The load-bearing steel plates 1 are welded to form elongated steel pipes, and concrete 6 is filled in the middle to form a double steel plate concrete shear wall (abbreviated as a shear wall). A layer of unbonded material 3 is wrapped outside the plastic zone at the bottom of the shear wall. The studs 9 are welded on the inner side of the load-bearing steel plate 1, and the studs 9 are symmetrically arranged in the horizontal direction of the two relative load-bearing steel plates 1, and each stud 9 is perpendicular to the load-bearing steel plate 1, and its function is to ensure that the load-bearing steel plate 1 Synergy with infill concrete6. The non-adhesive material 3 can be butyl rubber construction waterpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com