A selector shift mechanism for a transmission

A technology for gear selection and transmission, applied in the field of vehicle components, can solve the problems of abnormal noise caused by shift fork interference, increase in vehicle structure space, increase in vehicle manufacturing costs, etc., and achieve precise gear selection and shifting, and optimized design Space and the effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

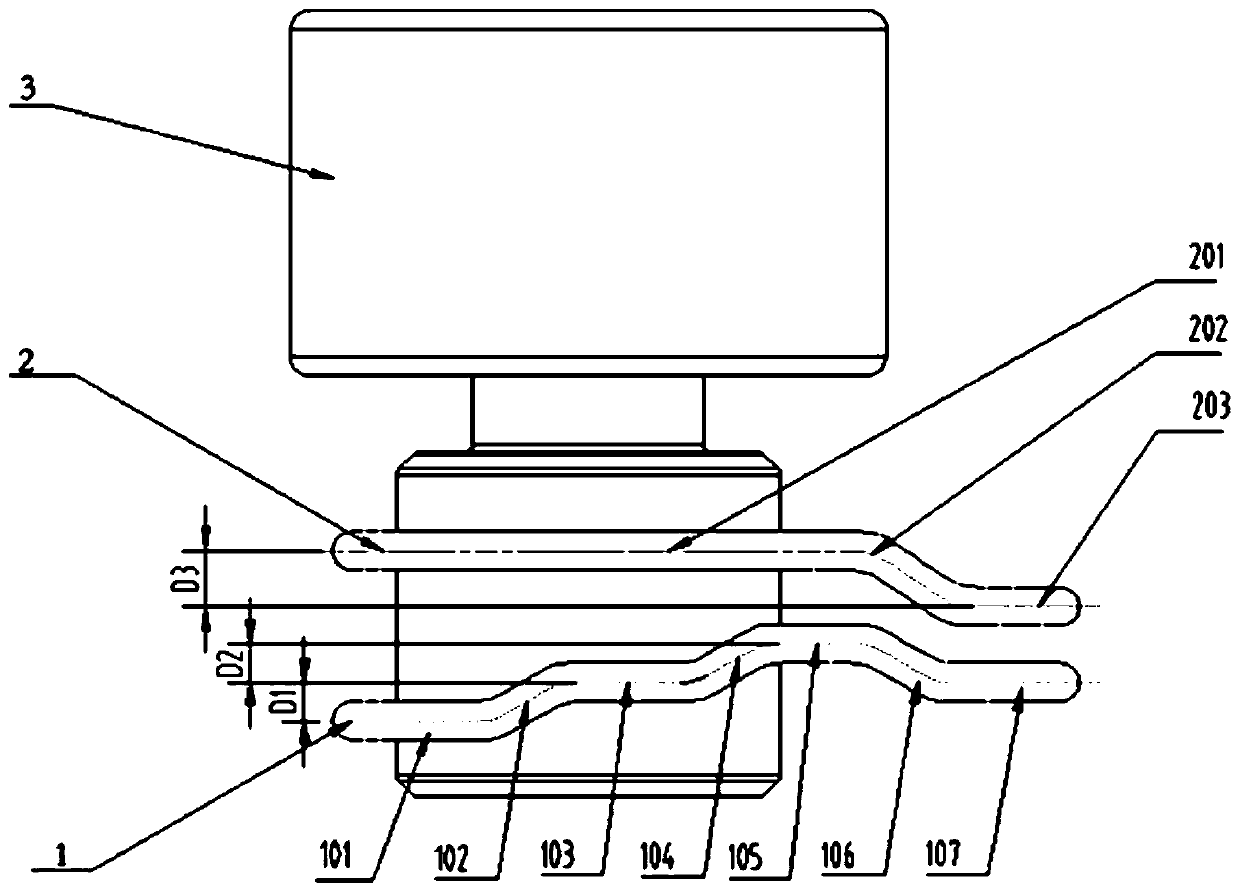

[0040] figure 1 It is a schematic structural diagram of a gear selection mechanism for a transmission according to an embodiment of the present invention, in order to solve the problem of realizing gear selection through an electric motor. Said shifting mechanism may generally comprise a drive motor 3 having an output shaft having an enlarged portion of increased diameter, a first notch 2 configured at the outer peripheral surface of said enlarged portion and a second notch 1 arranged at intervals from the first notch 2 and located on the outer peripheral surface of the enlarged portion, the first notch 2 and the second notch 1 each have at least one gear position, The gear selection mechanism also includes a first shift fork and a second shift fork, wherein, when the motor 3 rotates, the first shift fork can move along the first notch 2 with the rotation of the output shaft. move, so that the vehicle can be parked according to the gear position in the first notch 2, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com