Automatic control system for garbage efficient treatment

An automatic control system and garbage technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems affecting the effect of garbage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the technical solution of the present invention will be described in detail through specific examples.

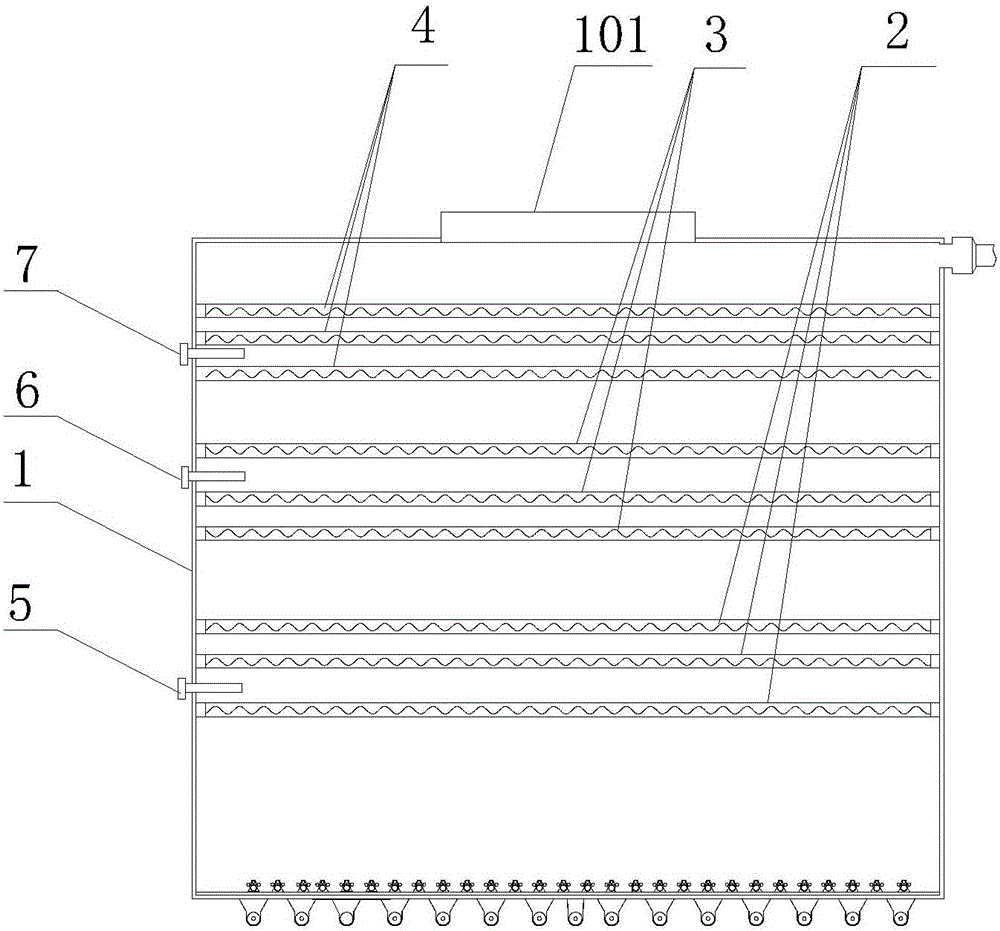

[0024] like figure 1 as shown, figure 1 It is a structural schematic diagram of an automatic control system for high-efficiency garbage disposal proposed by the present invention.

[0025] refer to figure 1 , an automatic control system for high-efficiency garbage disposal proposed by an embodiment of the present invention, including: a furnace body 1 for processing garbage, and a control device, wherein:

[0026] The top of the furnace body 1 is provided with a feeding port 101, and the feeding port 101 is provided with an end cover for sealing the feeding port 101; The first heating area, the second heating area and the third heating area, the first heating area, the second heating area, and the third heating area are arranged in sequence, and the first heating area is located on the side close to the bottom of the furnace body 1, and the first A distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com