Semiconductor refrigeration sheet and manufacturing method thereof

A technology for semiconductors and refrigeration sheets, applied in the field of semiconductor refrigeration sheets and their preparation, can solve the problems of limited bonding area between semiconductors and conductors, affecting the application of semiconductor refrigeration sheets, weak bonding force of thermal conductive layers, etc., so as to enhance mechanical properties and tensile properties. , It is not easy to slide, and the effect of reducing the requirements of the application environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

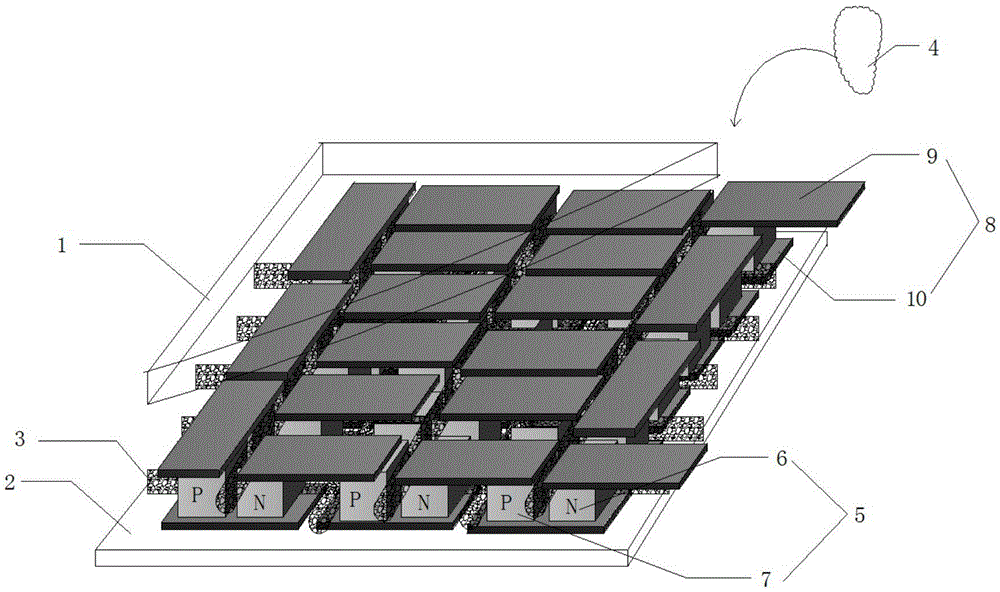

[0040] The present invention also provides a method for preparing a semiconductor refrigerating sheet, the method comprising: a. closely attaching a plurality of lower conductors 10 to the upper surface of the lower insulating and heat-conducting layer 2, and then placing a plurality of N / P type galvanic couples 5 The lower end is connected through the lower end conductor 10; wherein, the lower end of the N-type semiconductor element 6 and the P-type semiconductor element 7 in each N / P type galvanic couple pair 5 are connected to each other through a lower end conductor 10; b, each The upper end of the N-type semiconductor element 6 in the N / P type galvanic pair 5 is uniquely connected with the upper end of the P-type semiconductor element 7 in another adjacent N / P type galvanic pair 5 by an upper conductor 9; c, the Each of the upper-end conductors 9 is closely attached to the lower surface of the upper-end insulating and heat-conducting layer 1; wherein, insulating fibers 3 a...

Embodiment 1

[0051] Such as figure 1 As shown, place 10 pairs of N\P type galvanic couples between two layers of aluminum sheets (with a thickness of 0.5mm-1.0mm and a size of 20mm*200mm), spot welding the upper and lower aluminum sheets, and insulating glass fibers (non- Alkaline glass fibers) are interspersed horizontally and vertically in the semiconductor layer. Place the semi-conductor layer that penetrates the fiber in a container, then pour liquid epoxy resin into the fiber layer, place the container in a vacuum drying oven, vacuumize, and after the bubbles dissipate, add a curing agent, and after curing, remove from the vacuum Take it out from the drying oven, and process the complex into a metal matrix 1 with a thickness of 4 mm and a size of 20 mm×170 mm.

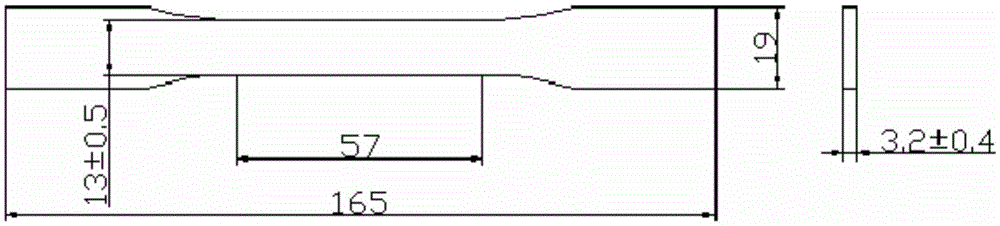

[0052] Gained metal substrate 1 is processed into such as figure 2 See Table 1 for the pull-out tensile strength of the tensile-type pull-out splines shown in Young's modulus.

[0053] It should be noted that Example 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com