High-torque motor and robot including the motor

A motor and high-torque technology, applied in the field of automation, can solve the problems of motor weight and volume increase, high motor cost, high cost of reducer, etc., and achieve the effect of reducing volume and quality, increasing torque, and stable torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the field of robotics, it is necessary to use electric motors (also known as motors) to drive the movement of each joint. However, because the movement of robots, especially industrial robots, usually need to bear a certain load, high-torque motors are required to meet the requirements of industrial robots. The motors in the prior art usually increase the torque by using a reducer, but on the one hand, the motor with this structure has high cost and high noise due to the reducer, so the cost of the entire motor is high and the noise is large, and because the reducer Existence causes the weight and volume of the motor itself to increase, so it is unfavorable to apply such a motor to a robot, especially a robot directly driven by the motor.

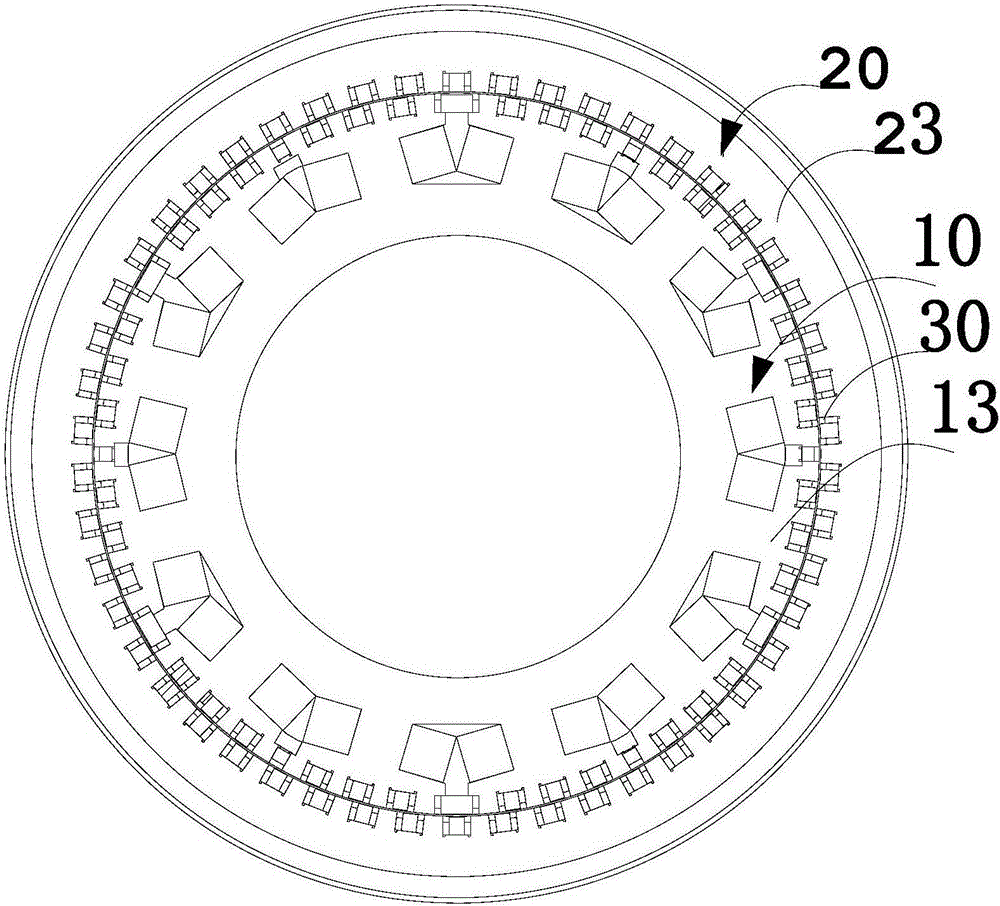

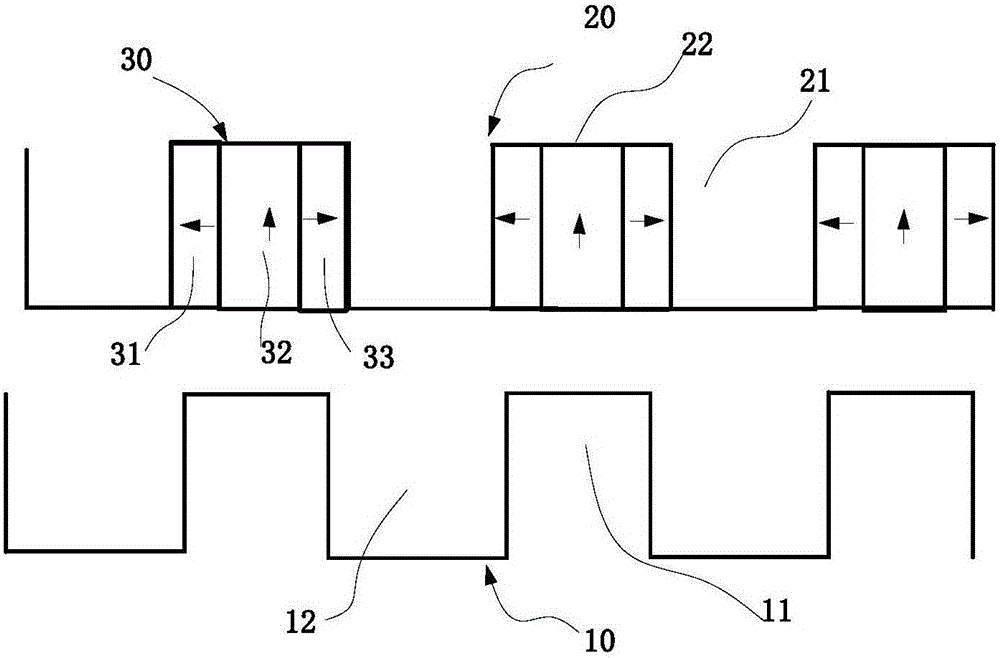

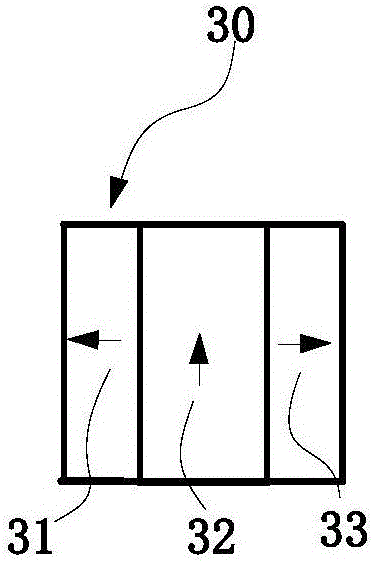

[0048] In order to solve the above problems, the present invention provides a high-torque motor. At least part of the stator magnetic-conducting part and the mover magnetic-conducting part include a high-flux magnetic-conducting pa...

Embodiment 2

[0168] Embodiment 2 of the present invention also provides a robot including the high-torque motor described in Embodiment 1.

[0169] As described in Embodiment 1, the greater the magnetic flux density, the greater the iron loss will be. When the motor moves at a high speed (such as in the field of automobile driving), excessive iron loss will be generated per unit time, resulting in serious heating of the motor. Then seriously affect the performance of the motor and even cause damage to the motor. However, the motor described in the embodiment of the present invention is suitable for use in the field of mainly low-speed operation (such as: robot). Since the motor only occasionally moves at high speed, it is not necessary to consider the iron loss factor, and a high magnetic flux density motor can be used. Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com