Driving control signal collecting device for groove wheel of seeding machine or fertilization seeding machine

A technology of drive control and signal acquisition, applied in fertilization devices, devices using optical methods, applications, etc., can solve the problems of out-of-synchronization of unit forward speed, unfavorable variable control and automatic control, high manufacturing cost, etc., and achieve accurate signal transmission And synchronous, easy to popularize and use on a large scale, improve the effect of reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

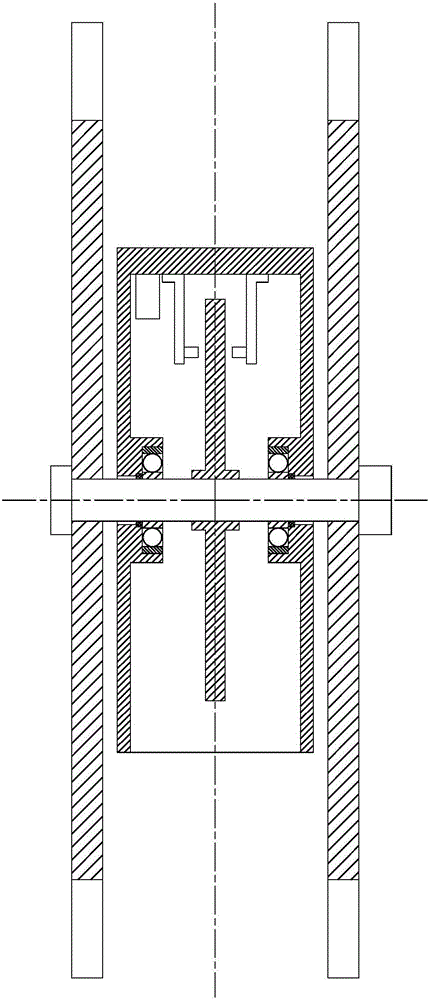

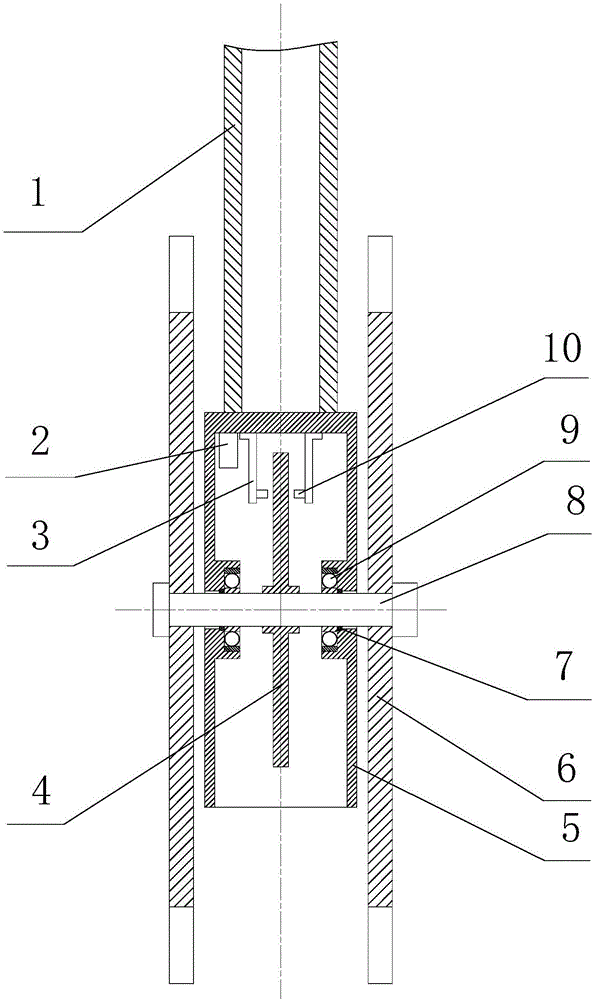

[0039] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] A driving control signal acquisition device for seeding or fertilizing sheave of a seeder or a fertilizing seeder. A rolling wheel that touches the ground and rotates as the seeder or fertilizing seeder moves forward is set on the seeder or fertilizing seeder. The output of the rotation is The electric signal is transmitted to the drive control device of the seeder or the fertilization seeder sheave 12.

[0041] The rotating shaft 8 of the scroll wheel collects electrical signals through the rotational speed sensor and transmits them to the drive control device of the sheave 12 of the seeder or fertilization seeder. The speed sensor is a reliable, conventional and practical instrument, easy to install and use.

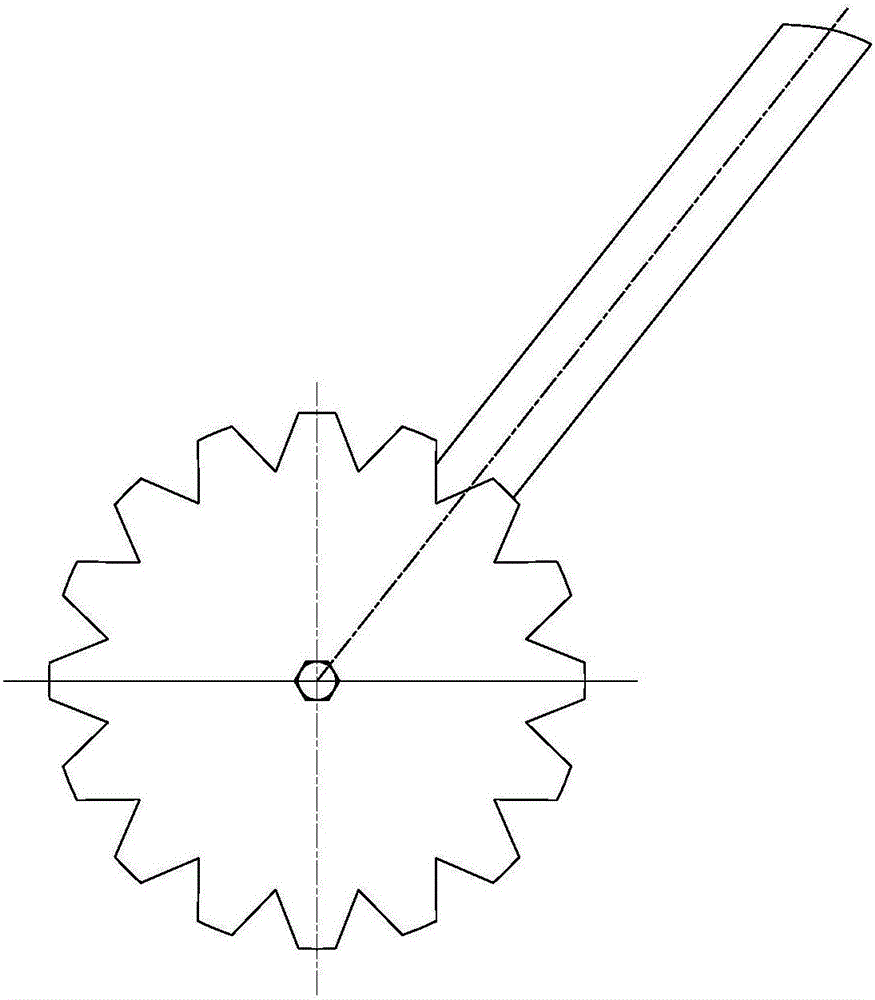

[0042] A grating disc 4 is installed on the rotating shaft 8 of the rolling wheel, and the infrared probe 10 on the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com