Ginger-milk-pudding ice cream and preparation method thereof

A technology of ginger bumping milk and ice cream, which is applied in the field of ginger bumping milk ice cream and its preparation, can solve the problems of monotonous taste, low nutritional value, and inability to meet higher and higher requirements, so as to increase the variety of ice cream and improve health care functions , the effect of enriching the ice cream market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

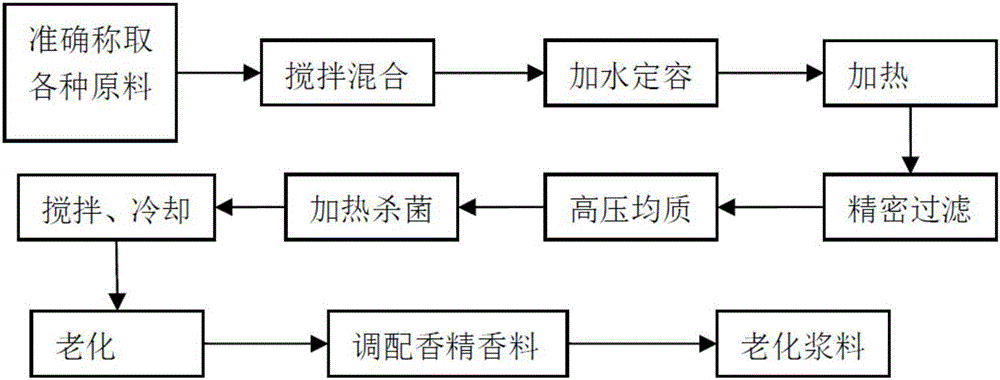

[0032] The present invention also provides a kind of preparation method of ginger milk ice cream, which comprises the following steps:

[0033] a. Preparation of slurry: add ginger juice, white granulated sugar, glucose syrup, milk powder, skimmed milk powder, dextrin, coconut oil, cream, and stabilizer in a clean batching pot in order, add hot water and mix evenly. Heating in a quantitative tank, aging after filtering, homogenizing and sterilizing, adding essence and pigment and stirring evenly for later use;

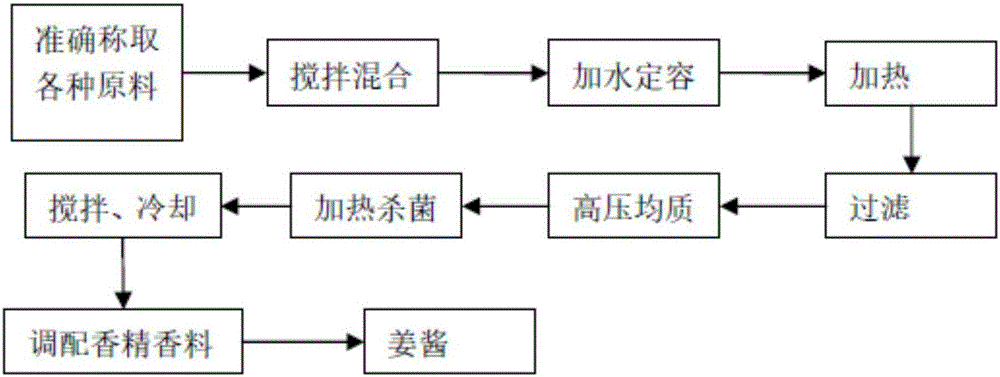

[0034] b. Preparation of ginger sauce: Add ginger juice, white granulated sugar, glucose syrup, condensed milk, glucose powder, brown sugar, and stabilizer in the order of the formula into the batching pot, add hot water and mix evenly, place in a quantitative tank to heat, after After filtering, homogenizing, sterilizing and cooling, add essence and pigment and stir evenly for later use;

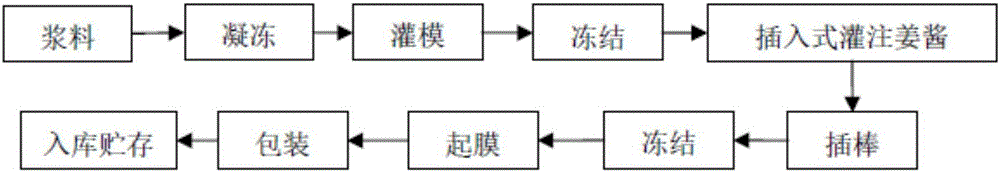

[0035] c. Mix the prepared slurry and ginger paste in proportion, freeze, mold...

Embodiment 1

[0047] 1) Preparation of ginger juice: select fresh and non-rotten ginger, wash and peel it, slice it, then grind the ginger tissue with a high-speed grinder, filter the ginger juice with clean gauze, and place the ginger juice at 4-5°C Keep fresh under the condition for later use.

[0048] 2) Preparation of slurry: Weigh 30kg of ginger juice, 150kg of white sugar, 50kg of glucose syrup, 60kg of milk powder, 60kg of skimmed milk powder, 20kg of dextrin, 45kg of coconut oil, 45kg of cream, and 3kg of stabilizer, and add them to a clean ingredient pot in turn , Add about 100kg of hot water and mix evenly; use a fluid pump to transport the evenly mixed feed liquid to the quantitative tank, use hot water to set the volume to 2500L, and then heat the feed liquid to 60-65°C. After the prepared feed liquid is filtered through 40 mesh, it is homogenized for 30s at a homogenization temperature of 60-70°C and a homogenization pressure of 15-18MPa, and then heated to 90°C by a plate heat...

Embodiment 2

[0052] 1) Preparation of ginger juice: select fresh and non-rotten ginger, wash and peel it, slice it, then grind the ginger tissue with a high-speed grinder, filter the ginger juice with clean gauze, and place the ginger juice at 4-5°C Keep fresh under the condition for later use.

[0053] 2) Preparation of slurry: Weigh 50kg of ginger juice, 140kg of white sugar, 60kg of glucose syrup, 50kg of milk powder, 50kg of skimmed milk powder, 15kg of dextrin, 50kg of coconut oil, 50kg of cream, and 4kg of stabilizer, and add them to a clean ingredient pot in turn , Add about 150kg of hot water and mix evenly; use a fluid pump to transport the evenly mixed feed liquid to the quantitative tank, use hot water to set the volume to 3000L, and then heat the feed liquid to 60-65°C. After the prepared feed liquid is filtered through 40 mesh, it is homogenized for 30s at a homogenization temperature of 60-70°C and a homogenization pressure of 15-18MPa, and then heated to 90°C by a plate heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com