Processing method of vacuum-packed skin silks

A technology of vacuum packaging and processing method, applied in the field of food processing, can solve the problems of being easily polluted, the way of eating is single, affecting the circulation of leather silk, etc., and achieve the effect of broad market application prospects, maintaining flavor and nutrition, and promoting economic development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

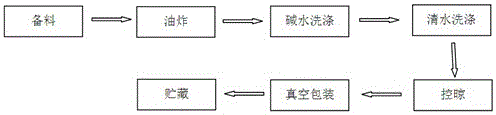

Image

Examples

Embodiment 1

[0026] The processing method of vacuum-packed leather silk in the present embodiment, preparation steps are as follows:

[0027] (1) Frying treatment: Heat the oil to 150°C, then pour the dried shredded skin into the oil, fry for 4 minutes, turn over during the frying, remove the shredded skin to control the oil after frying;

[0028] (2) Alkaline water washing: Dissolve edible alkali in hot water at 80°C, the mass fraction of the hot alkali solution is 0.4wt%, put the oil-controlling skin silk in step (1) into the hot alkali solution and rinse for 10 minutes, according to 50g Dried skin requires 1L of hot alkaline water, heated and rinsed for stirring, and then removed;

[0029] (3) Washing with clean water: Wash the leather silk rinsed in step (2) in clean water, generally three times, if necessary, wash several times, stir during the washing process, and remove after washing;

[0030] (4) Controlled drying: Dry the skin after washing with water in step (3) at room temperat...

Embodiment 2

[0034] The processing method of vacuum-packed leather silk in the present embodiment, preparation steps are as follows:

[0035] (1) Frying treatment: Heat the oil to 160°C, then pour the dried shredded skin into the oil, fry for 3 minutes, turn over during the frying, remove the shredded skin to control the oil after frying;

[0036] (2) Alkaline washing: Dissolve edible alkali in hot water at 85°C, the mass fraction of the hot alkali solution is 0.45wt%, put the oil-controlling skin silk in step (1) into the hot alkali solution and rinse for 15 minutes, according to 50g Dried skin requires 1L of hot alkaline water, heated and rinsed for stirring, and then removed;

[0037] (3) Washing with clean water: Wash the leather silk rinsed in step (2) in clean water, generally three times, if necessary, wash several times, stir during the washing process, and remove after washing;

[0038] (4) Controlled drying: Dry the skin after washing with water in step (3) at room temperature f...

Embodiment 3

[0042] The processing method of vacuum-packed leather silk in the present embodiment, preparation steps are as follows:

[0043] (1) Frying treatment: heat the oil to 170°C, then pour the dried shredded skin into the oil, fry for 2 minutes, stir during frying, remove the shredded skin to control the oil after frying;

[0044] (2) Alkaline washing: Dissolve edible alkali in hot water at 90°C, the mass fraction of the hot alkali solution is 0.5wt%, put the oil-controlling skin silk in step (1) into the hot alkali solution and rinse for 20 minutes, according to 50g Dried skin requires 1L of hot alkaline water, heated and rinsed for stirring, and then removed;

[0045] (3) Washing with clean water: Wash the leather silk rinsed in step (2) in clean water, generally three times, if necessary, wash several times, stir during the washing process, and remove after washing;

[0046] (4) Controlled drying: Dry the skin after washing with water in step (3) at room temperature for 50 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com