Telescopic folding knife spoon combination manufacture and installation technology

An installation process and folding technology, which is applied in the field of production and installation process of telescopic folding knife and spoon combination, can solve the problems of inability to guarantee product quality requirements and product functions, single production and manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

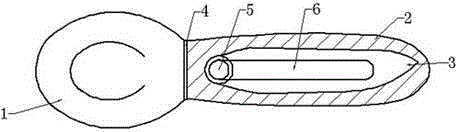

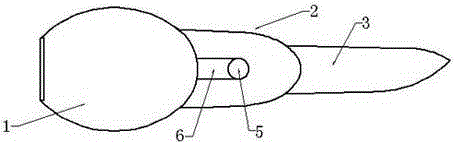

[0011] Taking telescopic folding knife and spoon combination as an example, accessories processing: Zinc alloy die-casting spoon 1, handle 2—handle 2 to clear the chute 6, spoon 1, handle 2 to remove casting burrs, polish, chrome plating—turning elastic folding shaft 4. Elastic locking sliding shaft 5, stamping tool 3—elastic folding shaft 4, elastic locking sliding shaft 5, surface derusting and polishing of tool 3; assembly: use elastic folding shaft 4 to install spoon 1 and spoon handle 2 into one -Install the tool 3 in the chute 6 of the spoon handle 2 with elastic locking slide shaft 5 -Connection part and appearance inspection, function test.

[0012] During the functional experiment, the elastic locking sliding shaft 5 of the knife 3 is slid out along the chute 6 to the rear end of the spoon handle 2, and folded along the elastic folding shaft 4 toward the spoon hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com