Prophy angle provided with novel polishing cup and capable of clockwise and anticlockwise rotating repeatedly of tooth polishing machine

A polishing machine, forward and reverse technology, applied in the direction of cleaning teeth, dentistry, gum massage, etc., can solve the problems of complex manufacturing of drive shaft and driven shaft, unable to inhibit the migration of polishing paste, and affect the efficiency of the operation process, etc., to achieve reduction Effects of small spatter, reduced burden, and increased polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

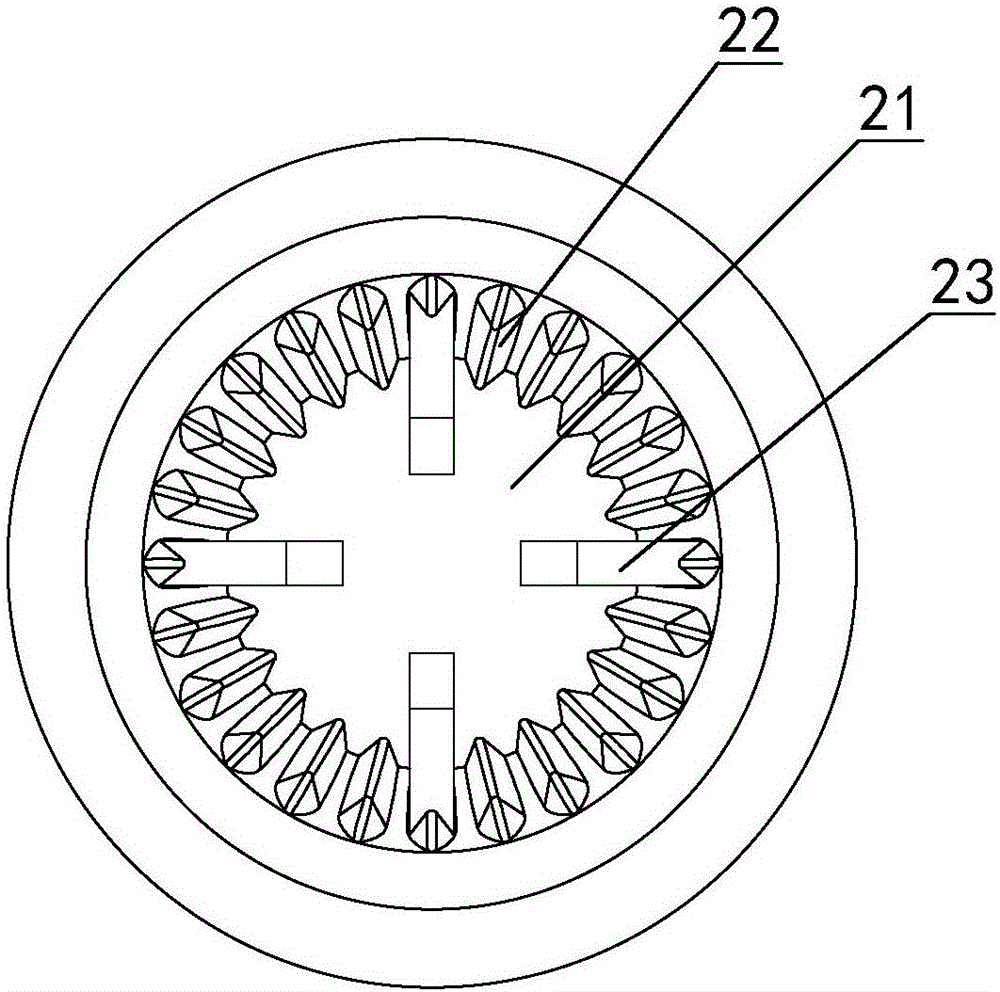

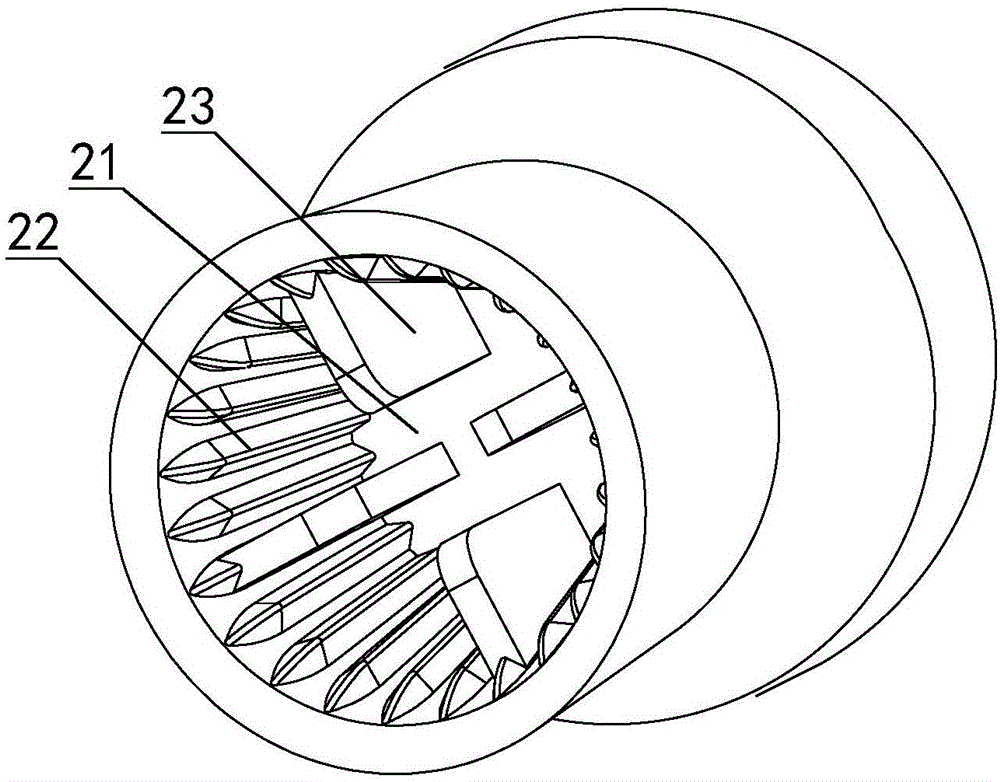

[0061] Example: see attached Figure 4-13 As shown, a tooth guard angle of a tooth polishing machine with a novel polishing cup and capable of repeating forward and reverse rotation includes a polishing cup and a driving assembly, the polishing cup is in transmission connection with the driving assembly, and the driving assembly is connected to the tooth polishing The motor output shaft drive connection of the machine;

[0062] The polishing cup includes a cup body 1 and a base 2. The cup body 1 is fixed to the front end of the base 2, and the back of the base 2 is rotatably arranged in the shell 3 of the mouth guard; the end of the cup body 1 The housing 3 is connected to the mouth guard angle of the dental scaler. The front end of the cup body 1 is the clean end. The interior of the cup body 1 is provided with a cavity 26 which expands toward the front end of the cup body. And the front part of the cavity 26 is open;

[0063] A number of first blades 27 are spirally arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com