Wet electric closed-loop control electricity saving method

A closed-loop control and power supply technology, applied in power supply technology, electrostatic separation, external electrostatic separator, etc., can solve the problem of high power consumption of wet electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

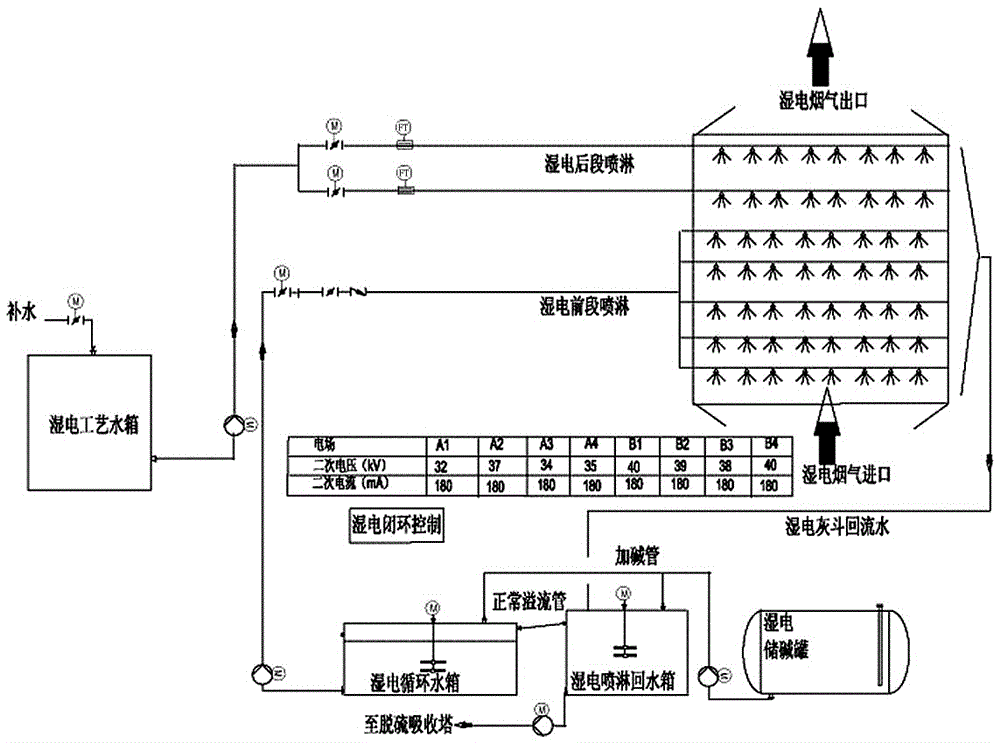

[0023] Example: such as figure 1 Shown is a schematic diagram of the wet power system. This figure shows that a row of wet electric fields is installed, and A1, A2, A3, A4, B1, B2, B3, and B4 are the four electric fields of the A and B channels respectively. There are also coal-fired generator sets installed with two rows of 8 electric fields or one row of 4 electric fields. The closed-loop control of various electric field parameters of wet electricity by using chimney smoke concentration in the present invention is applicable in various situations, and it is only necessary to introduce signals into each electric field power source for control at the same time. Click the "wet electricity closed-loop control" button to enter the wet electricity closed-loop control setting module.

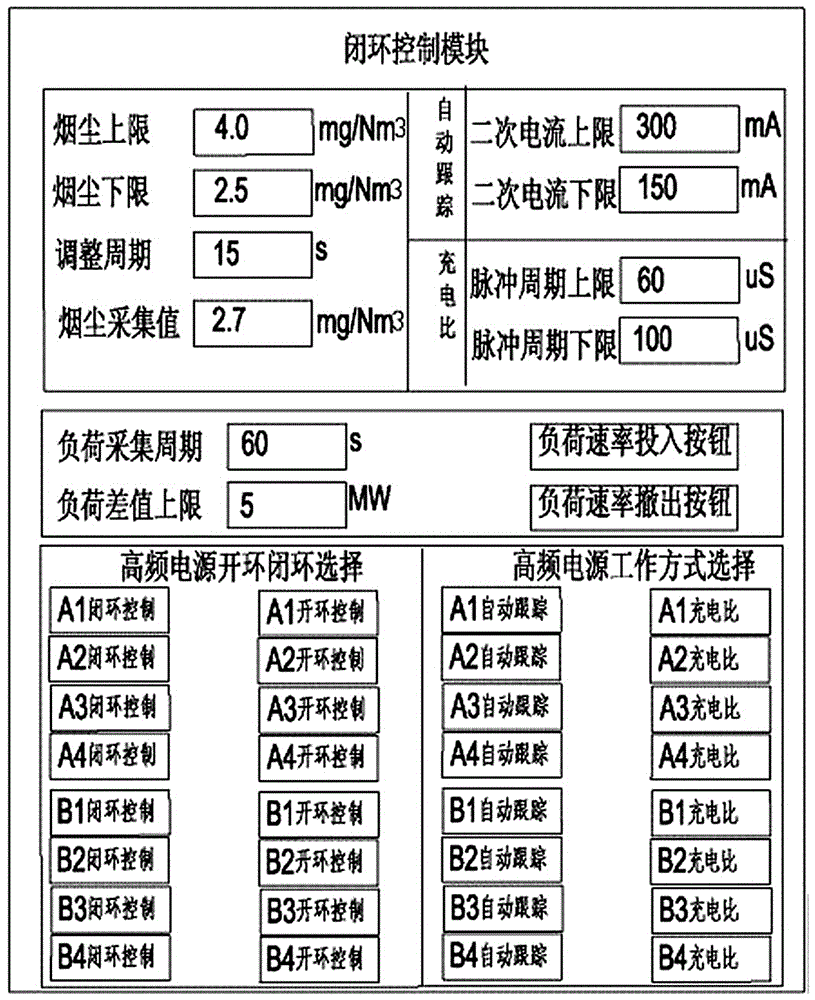

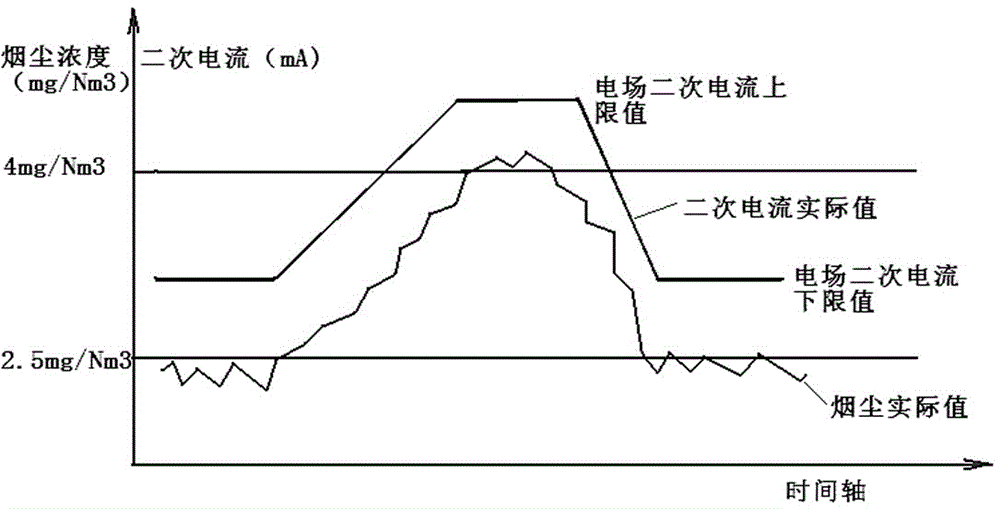

[0024] Such as Figure 2-3 As shown, it is a schematic diagram of the "wet electricity closed-loop control setting" module and the closed-loop automatic control curve. Set the upper and lower lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com