Cast iron pipe anti-leakage layer mark detecting and smearing system

A technology of marking detection and anti-leakage layer, used in liquid/vacuum measurement for liquid tightness, jetting device, etc., can solve the problems of great impact on human health, high cost of type board, complicated installation of testing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

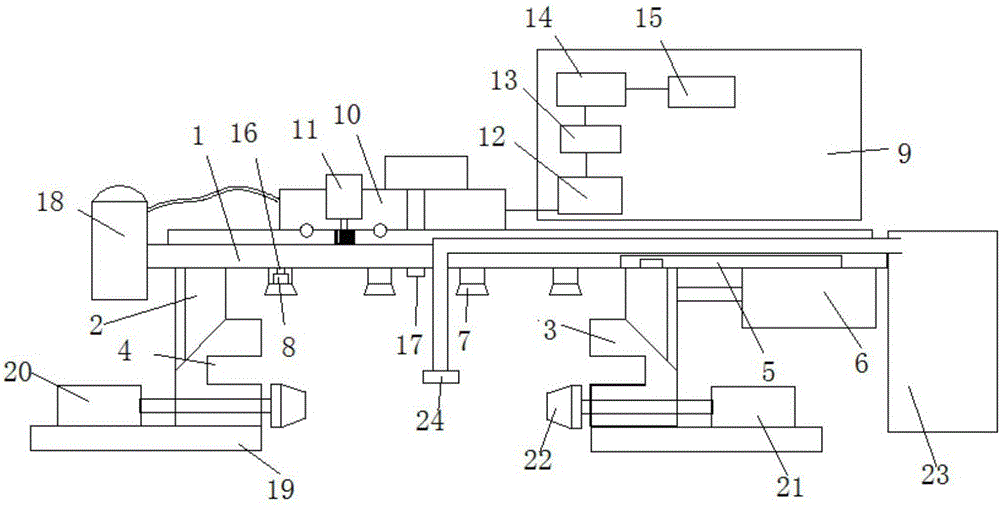

[0010] Referring to the accompanying drawings, a cast iron pipe leak-proof layer marking detection and smearing system includes a beam plate 1, left and right pipe clamps 2, 3, and the lower surface of the beam plate 1 is provided with left and right pipe clamps 2, 3 3. A bottom plate 19 is provided on the side walls of the left and right pipe clamps 2 and 3, a hydraulic cylinder 20 is fixedly installed on the left bottom plate, and a rotating motor 21 is provided on the right pipe clamp. The piston rod 20 and the shaft end of the motor 21 are respectively provided with a top block 22, the right end of the beam plate is provided with an asphalt tank 23, the asphalt tank 23 is connected with a spray pipe 24, the left and right pipe clamps 2, The side wall of 3 is provided with a bayonet 4, the upper end of the right pipe clamp 3 is slidably clamped in the chute 5, the side wall of the right pipe clamp 3 is connected with a cylinder 6, and the cylinder 6 is fixed on the beam. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap