Plate twisting formation device and method

A technology for a plate and a fastening device, applied in the field of plate processing, can solve the problems of many factors affecting the bending angle, difficult to precisely control the bending angle, and high cost, and achieve the effects of improving labor efficiency, saving costs and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

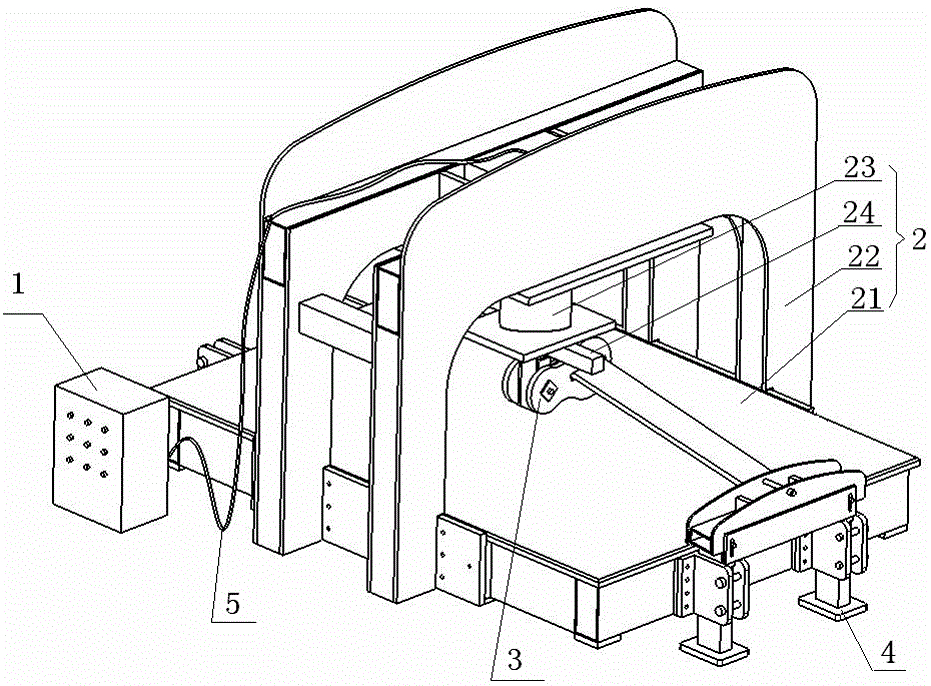

[0022] Embodiment 1 Plate distortion forming device

[0023] refer to figure 1 , the forming device of the present invention includes: a hydraulic base station 1, a gantry press 2 connected to the hydraulic base station 1, a twisting device 3 arranged on the gantry press 2, and a fastening device 4 for fixing a plate; wherein, the The gantry press 2 includes a platform 21, a U-shaped gantry 22 arranged on the platform, a hydraulic cylinder 23 arranged on the U-shaped gantry 22 and connected to the hydraulic base station 1 through a hydraulic pipeline 5, and one end of the hydraulic cylinder 23 is provided There is a clip 24 engaged with the twisting device 3 .

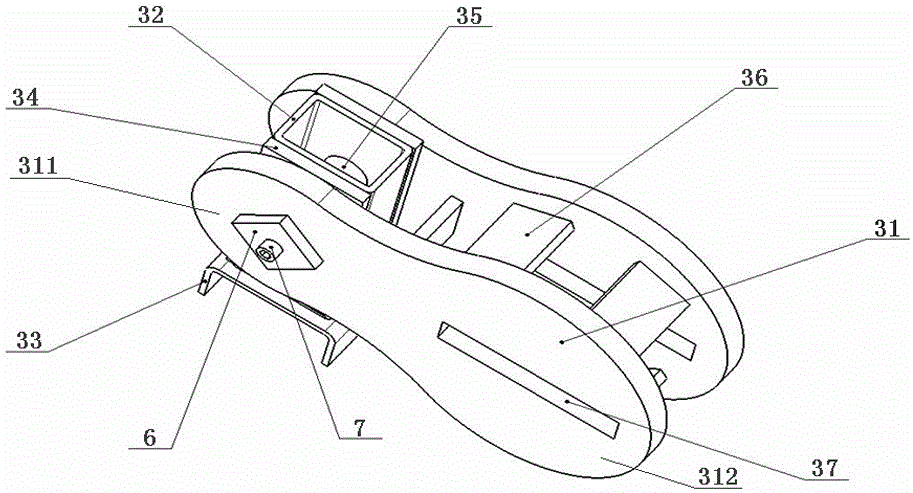

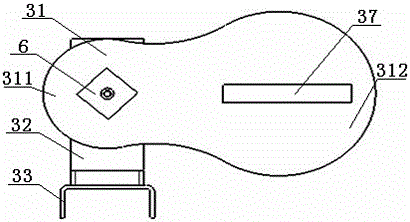

[0024] refer to figure 2 , image 3 , the torsion device 3 includes two torsion plates 31 symmetrically arranged, the two torsion plates are insole type, the torsion plate 31 includes a small ellipse connecting end 311 and a large ellipse torsion end 312, the small ellipse of the two torsion plates A standpipe 32 ...

Embodiment 2

[0027] Embodiment 2 Use the sheet material twisting forming device described in Example 1 to carry out a 500mm long sheet material

[0028] Rows are twisted into shape.

[0029] 1. Adjust the twisting device 3 so that the feeding port 37 on the twisting device 3 and the connecting shaft 35 are on the same horizontal line (such as image 3 shown); then insert one end of the plate to be formed with a length of 500 mm into the feed ports 37 of the two twisted plates, so that the plate is most suitable for 50 mm exposed at the end of the twisting device, which saves the cost of the plate and does not affect the twisting forming; The other end of the plate is fixed on the platform 21 using a fastening device 4;

[0030] 2. Connect the jig 24 on the gantry press 2 with the concave plate 33 on the twisting device 3, start the hydraulic base station 1, and make the hydraulic cylinder 23 move downward. The pressure generated by the hydraulic cylinder 23 when it moves up and down is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com