Printing head heating device and heating method of 3D (Three-dimensional) printer based on eddy-current effect

A technology of 3D printers and heating devices, applied in the direction of processing heating elements, manufacturing auxiliary devices, 3D object support structures, etc., can solve the problems of low heating efficiency, incomplete melting, uneven heating, etc., and achieve easy control of heating temperature and increase High printing accuracy and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

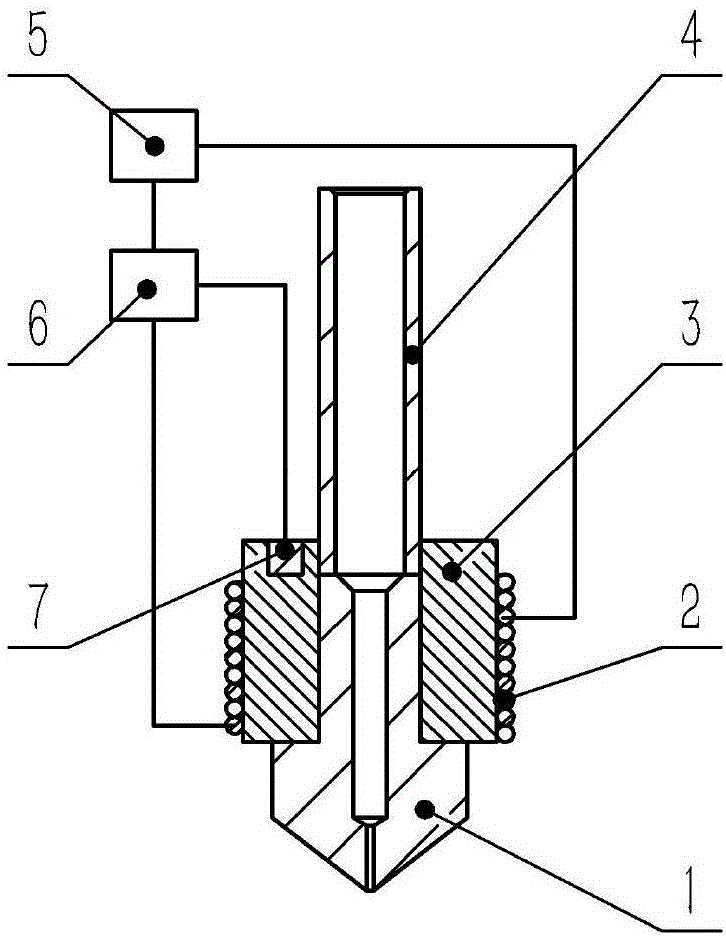

[0026] See attached figure 1 , the print head heating device of the 3D printer of the present invention comprises a nozzle (1), a coil (2), a heating block (3), a throat (4), a power supply (5), a temperature control system (6), a temperature sensor (7).

[0027] The coil (2) is wound outside the heating block (3), the temperature measuring sensor (7) is placed in the temperature measuring hole of the heating block (3) and connected to the temperature control system (6) with a wire, and the upper end of the nozzle (1) is connected to Installed inside the heating block (3) (for example, can be connected by common methods in the field such as threads), the throat pipe (4) is installed on the upper part of the heating block (3) for connecting the print head and the movement mechanism; It enters the nozzle (1) through the throat (4).

[0028] The power supply (5), temperature control system (6) and coil (2) are connected in series, and the power supply (5) is preferably alternat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com