Stacked sheet plate containing mechanism of multifunctional plate receiving machine

A multi-functional, spring-loaded technology, applied in the direction of conveyors, object stacking, transportation and packaging, etc., can solve the problems of inability to achieve complete automation, automatic loading and unloading, low degree of mechanization, etc., and achieve simple structure, manual The effect of low cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

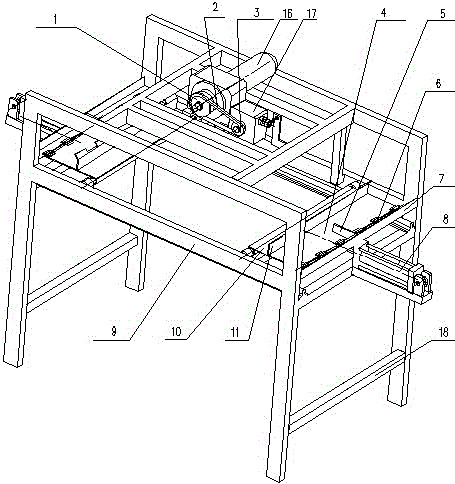

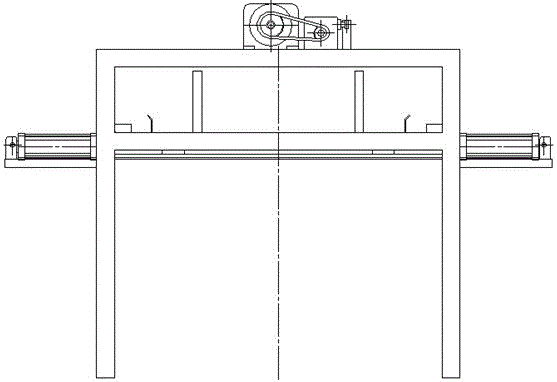

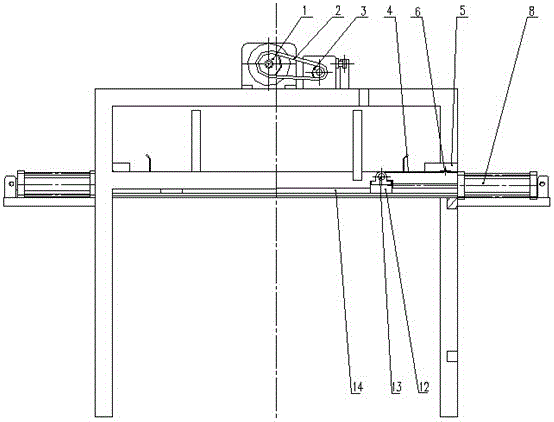

[0016] Embodiment 1, with reference to accompanying drawing, frame (9) is made through modes such as welding, wedge joint, bolt with angle iron, round iron, pipe material plate. The bottom edge of the frame (9) has a reinforcement bar (18). Frame (9) is a framework, is made of side frame (7), supporting plate (14) and reinforcing bar (18). Electromagnetic geared motor (16) and speed governor (17) are installed on the top surface of frame (9). There is motor belt pulley (1) in front of electromagnetic geared motor (16), and reducer belt pulley (3) in front of speed governor (17). ), the drive belt (2) is connected between the reducer pulley (3) and the motor pulley (1) of the electromagnetic deceleration motor (16), and the top of the inner cavity of the frame (9) is for installing the wood chips obtained from the sawing machine The board receiving position, below the parts of the receiving mechanism is the palletizing board mechanism of the present invention. The plate unloa...

Embodiment 2

[0017] Embodiment 2, with reference to Embodiment 1, and with reference to the accompanying drawings, consists of the connecting spring plate (4), the stroke limit block (5), the spring plate loose-leaf (6), the side frame (7), the plate unloading cylinder (8), Frame (9), stacking plate (10), stacking baffle plate (11), bearing seat (12), shaft (13) and guide rail (15) are composed of stacking sheet assembly mechanism installed on the second joint. The board mechanism installation point (20), the second board connection mechanism installation point (20) is located below the first board connection mechanism installation point (19) of the previous process, and the first board connection mechanism installation point (19) is located on the frame (9 ) on both sides of the upper part. Below the first board-connecting mechanism installation point (19) is the second board-connecting mechanism installation point (20) of the stacking sheet assembly mechanism installed. The wooden board...

Embodiment 3

[0018] Embodiment 3, a multi-functional board-connecting machine stacking pallet assembly mechanism, including a motor pulley, a transmission belt, a reducer pulley, a spring board for connecting boards, a travel limit block, a spring board loose-leaf, a side frame, and a board-unloading cylinder , frame, stacking plate, stacking baffle, bearing seat, shaft, pallet, guide rail, electromagnetic geared motor, governor, reinforcing bar, it is characterized in that electromagnetic geared motor (16 ) and the governor (17), the motor pulley (1) of the electromagnetic deceleration motor (16) is connected to the governor (17) through the transmission belt (2), and the unloading cylinder (8) is installed outside the side frame (7), The spring leaf (6) is installed on the inner side of the side frame (7), the travel limiter (5) is installed on the inner side of the side frame (7), and the front of the travel limiter (5) faces the stacking baffle (11), The front of the spring leaf (6) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com