Energy-saving pre-treatment type biological purification device for sewage

A sewage biological and purification device technology, applied in biological treatment devices, filtration treatment, water/sewage treatment, etc., can solve problems such as high energy consumption, impact on sewage treatment effects, sewage treatment accidents, etc., and achieve enhanced nitrogen and phosphorus removal effects , Enhance the effect of pretreatment and improve the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

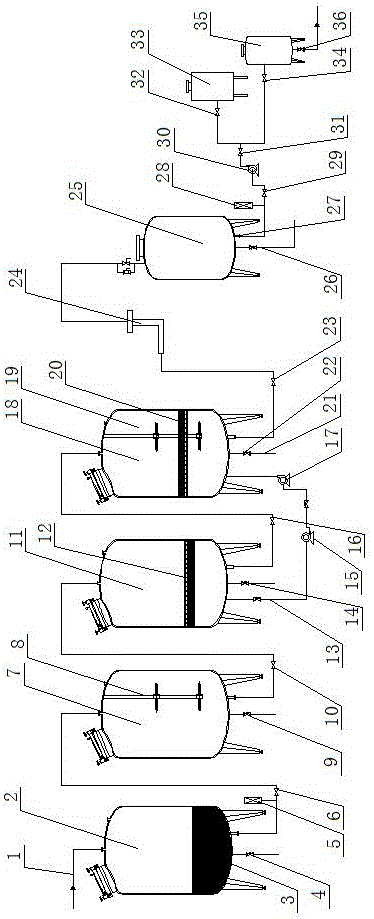

[0019] Such as figure 1 As shown, the energy-saving pretreatment sewage biological purification device includes a hydrolytic acidification biological tank 2, a pre-reaction tank 7, a continuous aeration water tank 11 and a sequence batch biological reaction water tank 18 connected in sequence.

[0020] The water inlet pipe 1 is connected to the upper part of the hydrolytic acidification biological box 2, the biological reaction filler 3 is arranged in the hydrolytic acidification biological box 2, and the first drain valve 4 is connected to the bottom of the hydrolytic acidification biological box 2.

[0021] Connect the first flow meter 5 and the first pneumatic angle seat valve 6 on the pipeline between the hydrolytic acidification biological box 2 and the pre-reaction box 7, connect the submersible mixer 8 in the pre-reaction box 7, and at the bottom of the pre-reaction box 7 Connect the second blowdown valve 9.

[0022] The second pneumatic angle seat valve 10 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com