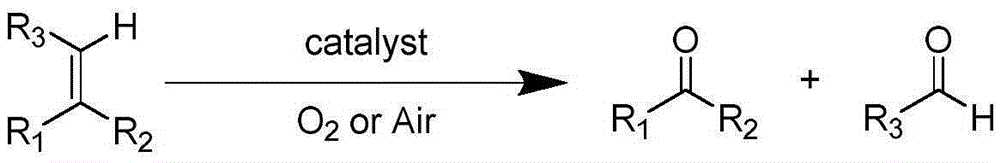

Method for preparing aldehyde ketone by catalyzing carbon-carbon double-bond oxidative cleavage

A technology of oxidative cleavage and carbon double bonds, applied in the field of chemical engineering, can solve problems such as low selectivity of by-products, waste discharge, and environmental pollution of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

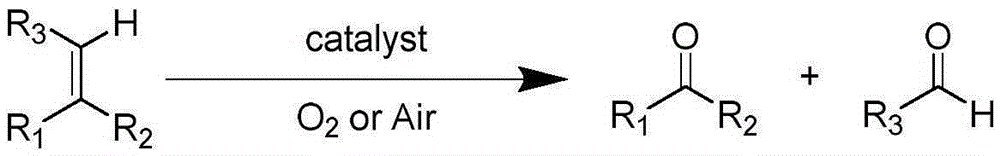

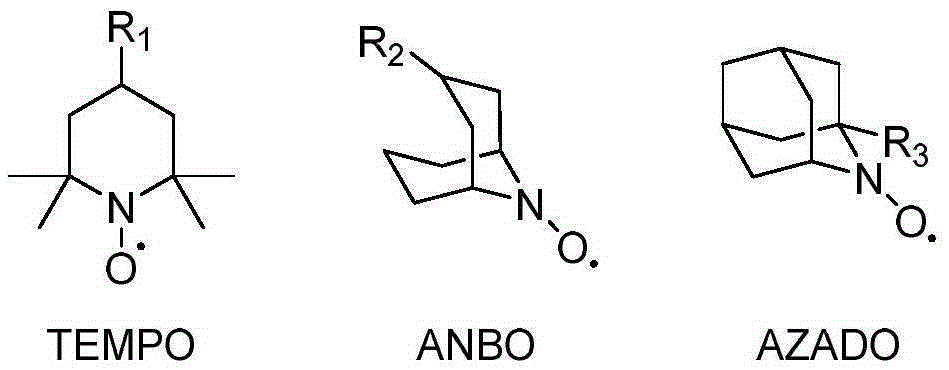

Embodiment 1

[0014] Add 0.05mmol of ABNO, 0.05mmol of FeCl3, 0.5mmol of α-methylstyrene, and 1mL of acetonitrile into a Schlenk bottle as a solvent, oxygen bulbs as an oxygen source, and stir and react at 60°C for 12h to obtain the target The product, the chromatographic yield is 90%.

Embodiment 2

[0016] Add 0.05mmol of ABNO, 0.05mmol of FeCl3, 0.5mmol of 4-methyl-α-methylstyrene, and 1mL of acetonitrile into a Schlenk bottle as a solvent, oxygen bulbs as an oxygen source, and stir the reaction at 60°C for 12h , the target product can be obtained with a chromatographic yield of 89%.

Embodiment 3

[0018] Add 0.05mmol of ABNO, 0.05mmol of FeCl3, 0.5mmol of 4-methoxy-α-methylstyrene, and 1mL of acetonitrile into a Schlenk bottle as a solvent, oxygen bulbs as an oxygen source, and stir the reaction at 60°C After 12 hours, the target product can be obtained with a chromatographic yield of 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com