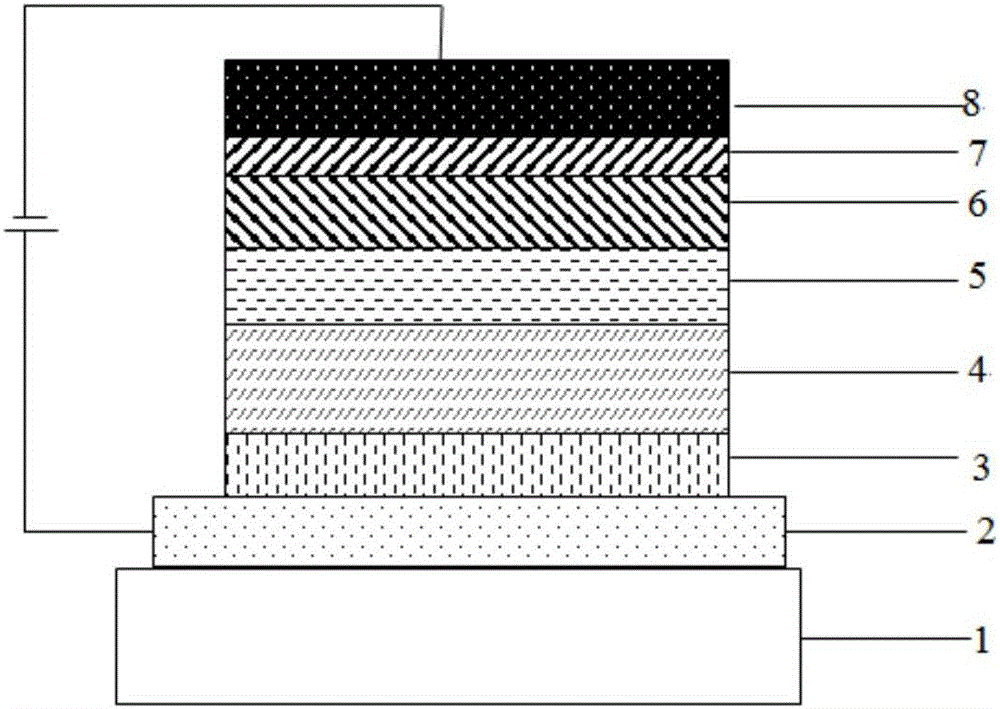

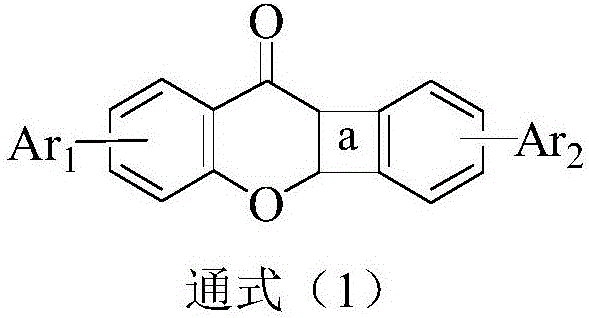

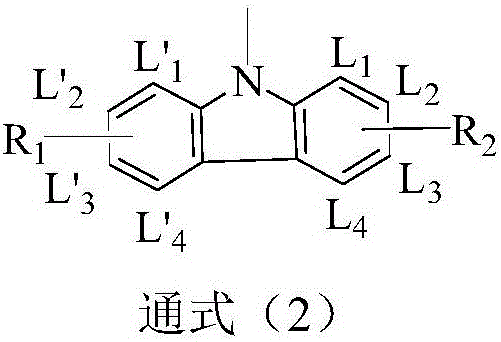

Compound taking heteroatom-containing benzfluorenone as core and application of compound to organic electroluminescence device

A technology of benzofluorenone and compounds, applied in the application field of organic electroluminescent devices, can solve problems such as performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: the synthesis of compound 4:

[0078]

[0079] Dissolve 0.1mol raw material A1 and 0.12mol intermediate G1 in 150mL anhydrous toluene, add 0.005mol Pd after deoxygenation 2 (dba) 3 and 0.15mol tri-tert-butylphosphine, and reacted at 110°C for 24 hours under an inert atmosphere. During the reaction, the reaction process was constantly monitored by TLC. After the raw materials were completely reacted, cooled and filtered, the filtrate was rotary evaporated to remove the solvent, and the crude product was filtered. Silica gel column, the intermediate target product was obtained, the HPLC purity was 99.1%, and the yield was 75.7%;

[0080] Elemental analysis structure (molecular formula C 42 h 30 N 2 o 2 ): theoretical value C,84.82; H,5.08; N,4.71; test value: C,84.85; H,5.07; N,4.71;

[0081] MS m / z: 595.98[M+H] + , theoretical value: 595.71.

Embodiment 2

[0082] Embodiment 2: the synthesis of compound 13:

[0083]

[0084] Dissolve 0.1mol raw material A1 and 0.12mol intermediate G2 in 150mL anhydrous toluene, add 0.005mol Pd after deoxygenation 2 (dba) 3 and 0.15mol tri-tert-butylphosphine, and reacted at 110°C for 24 hours under an inert atmosphere. During the reaction, the reaction process was constantly monitored by TLC. After the raw materials were completely reacted, cooled and filtered, the filtrate was rotary evaporated to remove the solvent, and the crude product was filtered. Silica gel column, the intermediate target product was obtained, the HPLC purity was 99.4%, and the yield was 73.4%;

[0085] Elemental analysis structure (molecular formula C 42 h 30 N 2 o 2 ): theoretical value C,84.82; H,5.08; N,4.71; test value: C,84.84; H,5.07; N,4.70;

[0086] MS m / z: 595.87[M+H] + , theoretical value: 595.71.

Embodiment 3

[0087] Embodiment 3: the synthesis of compound 30:

[0088]

[0089] Dissolve 0.1mol raw material A1 and 0.12mol intermediate G3 in 150mL anhydrous toluene, add 0.005mol Pd after deoxygenation 2 (dba) 3 and 0.15mol tri-tert-butylphosphine, and reacted at 110°C for 24 hours under an inert atmosphere. During the reaction, the reaction process was constantly monitored by TLC. After the raw materials were completely reacted, cooled and filtered, the filtrate was rotary evaporated to remove the solvent, and the crude product was filtered. Silica gel column, the intermediate target product was obtained, the HPLC purity was 99.3%, and the yield was 77.2%;

[0090] Elemental analysis structure (molecular formula C 39 h 24 N 2 o 3 ): theoretical value C,82.38; H,4.25; N,4.93; test value: C,82.40; H,4.25; N,4.92;

[0091] MS m / z: 569.94[M+H] + , theoretical value: 569.63.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com