Anti-adhesion and slipping agent master batch and preparation method thereof

A slip agent and anti-blocking agent technology, which is applied in the field of anti-opening slip agent masterbatch and its preparation, can solve the problems of easy crystal point, irregular particle shape, easy water absorption, etc., and achieve low friction coefficient, excellent anti-opening performance, The effect of low risk of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

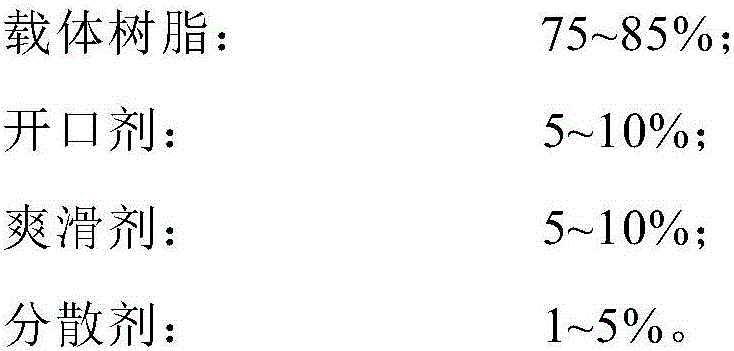

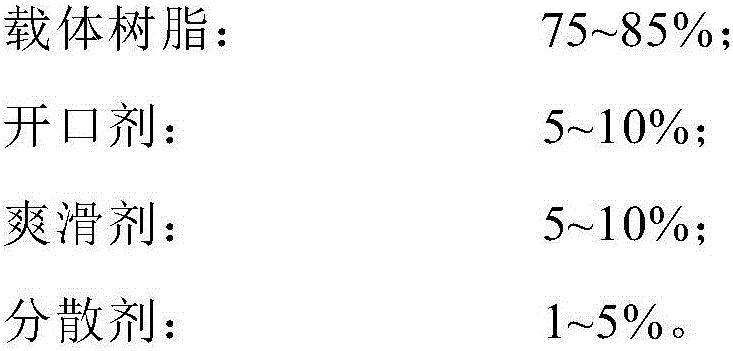

Method used

Image

Examples

Embodiment 1

[0022] A high-efficiency open-smooth masterbatch, its components are proportioned by mass percentage: 88% of linear low-density polyethylene with a melting index of 2g / 10min, 5% of spherical silica-alumina, 5% of erucamide, and number-average molecular weight 2% for 3000 Polyethylene Wax.

[0023] The preparation method comprises the following steps: adding linear low-density polyethylene, spherical silica alumina, erucamide, and polyethylene wax into a high-speed mixer and stirring at a low speed for 5 minutes, sending the mixture into a twin-screw extruder for melting and blending, and passing The shearing and mixing of the screw make the filler uniformly dispersed in the carrier resin, and then extrude, cool, dry, pelletize and pack to obtain the product of the invention. The temperature distribution of the twin-screw extruder is: from the feed section to the head: 90°C, 150°C, 170°C, 175°C, 180°C, 180°C, 170°C and 170°C, and the head temperature is 170°C °C; the feeding s...

Embodiment 2

[0025] A high-efficiency open-smooth masterbatch, its components are proportioned by mass percentage: 83% of linear low-density polyethylene with a melting index of 7g / 10min, 6% of spherical silica-alumina, 8% of erucamide, and number-average molecular weight 3000 Polyethylene Wax 3%.

[0026] The preparation method comprises the following steps: adding linear low-density polyethylene, spherical silica alumina, erucamide, and polyethylene wax into a high-speed mixer and stirring at a low speed for 5 minutes, sending the mixture into a twin-screw extruder for melting and blending, and passing The shearing and mixing of the screw make the filler uniformly dispersed in the carrier resin, and then extrude, cool, dry, pelletize and pack to obtain the product of the invention. The temperature distribution of the twin-screw extruder is: from the feed section to the head: 80°C, 140°C, 160°C, 165°C, 170°C, 170°C, 160°C and 160°C, and the head temperature is 160°C ℃; the feeding screw ...

Embodiment 3

[0028] A high-efficiency open-smooth masterbatch, its components are proportioned by mass percentage: 83% of linear low-density polyethylene with a melt index of 20g / 10min, 5% of spherical silica-alumina, 10% of oleic acid amide, and number-average molecular weight 2% for 3000 Polyethylene Wax.

[0029] The preparation method comprises the following steps: adding linear low-density polyethylene, spherical silica-alumina, oleic acid amide, and polyethylene wax into a high-speed mixer and stirring at a low speed for 5 minutes, sending the mixture into a twin-screw extruder for melting and blending, passing The shearing and mixing of the screw make the filler uniformly dispersed in the carrier resin, and then extrude, cool, dry, pelletize and pack to obtain the product of the invention. The temperature distribution of the twin-screw extruder is: from the feed section to the head: 80°C, 130°C, 150°C, 155°C, 160°C, 160°C, 150°C and 150°C, and the head temperature is 150°C ℃; the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Financial index | aaaaa | aaaaa |

| Financial index | aaaaa | aaaaa |

| Financial index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com