A homogeneous heat treatment process for aluminum alloys used in aviation

A technology of homogenization heat treatment and homogenization treatment, applied in the field of high-strength aluminum alloy heat treatment, can solve problems such as affecting production efficiency and slow heating speed, and achieve the effects of improving productivity, reducing total time, and improving homogenization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

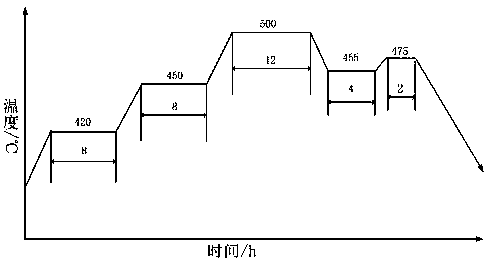

Embodiment example 1

[0045] The aluminum alloy casting ingot for aviation has good effect after homogenization treatment at 420℃×8h+450℃×8h+475℃×12h. Compared with the as-cast structure, the coarse eutectic structure at the grain boundary basically disappears, and only a small amount of structure It is no longer continuous, disconnected, granular or short-line, and the grain boundary is no longer obvious. After energy spectrum analysis, the energy spectrum analysis results are shown in Table 2. Zn element diffusion is completed, and the grain boundary no longer contains Zn element. The granular and short-line elements are mainly Al, Cu, and Mg, and there is no more brittle T phase, mainly composed of S phase and θ phase.

[0046] Table 2 Energy spectrum analysis results of homogenized three-stage heat treatment process

[0047] Element

Embodiment example 2

[0049] The aluminum alloy casting ingot for aviation has good effect after homogenization treatment at 420℃×7h+450℃×7h+475℃×11h. Compared with the as-cast structure, the coarse eutectic structure at the grain boundary basically disappears, and only a small amount of structure It is no longer continuous, disconnected, granular or short-line, and the grain boundary is no longer obvious. After energy spectrum analysis, the results of energy spectrum analysis are shown in Table 3. The Zn element has basically diffused, and the content is extremely low. The grain boundary is granular and short-line The main elements are Al, Cu, Mg, no more brittle T phase, mainly composed of S phase and θ phase.

[0050] Table 3 Energy spectrum analysis results of homogenized three-stage heat treatment process

[0051] Element

Embodiment 3

[0053] The aluminum alloy ingot for aviation use is homogenized at 420℃×6h+450℃×6h+475℃×10h, and the effect is good. Compared with the as-cast structure, the coarse eutectic structure at the grain boundary basically disappears, and only a small amount of structure It is no longer continuous, disconnected, granular or short-line, and the grain boundary is no longer obvious. After energy spectrum analysis, the energy spectrum analysis results are shown in Table 3. Zn element diffusion is completed, and the grain boundary no longer contains Zn element. The granular and short-line elements are mainly Al, Cu, and Mg, and there is no more brittle T phase, mainly composed of S phase and θ phase.

[0054] Table 4 Homogenized three-stage heat treatment process energy spectrum analysis results

[0055] Element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com