Energy-saving and environment-friendly waste gas treating hot water heater and treatment method thereof

A technology for hot water heaters and waste gas treatment, applied in water heaters, fluid heaters, combustion methods, etc., can solve the problems of increasing equipment procurement costs and daily operating costs, consuming energy to produce heat, and insufficient gas incineration, etc. Achieve the effect of reducing manpower, fast heating speed and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

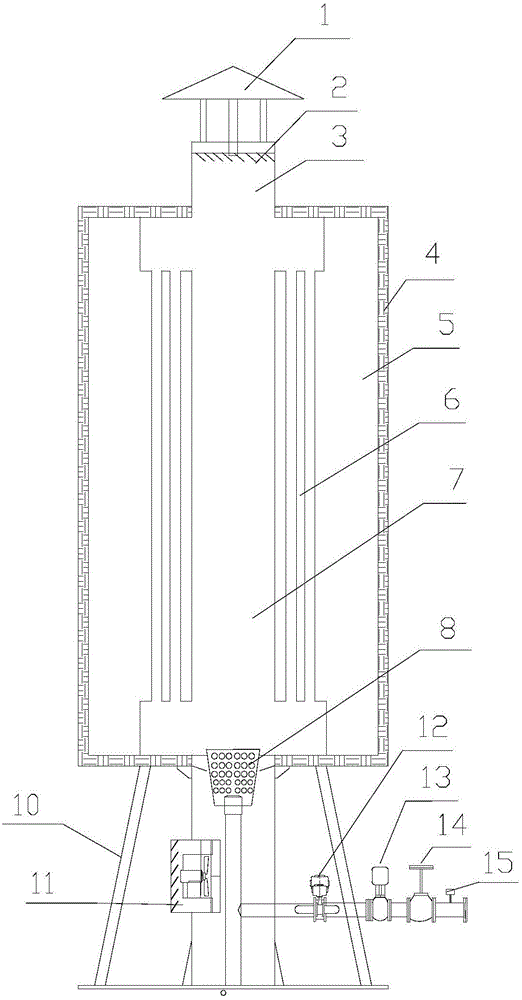

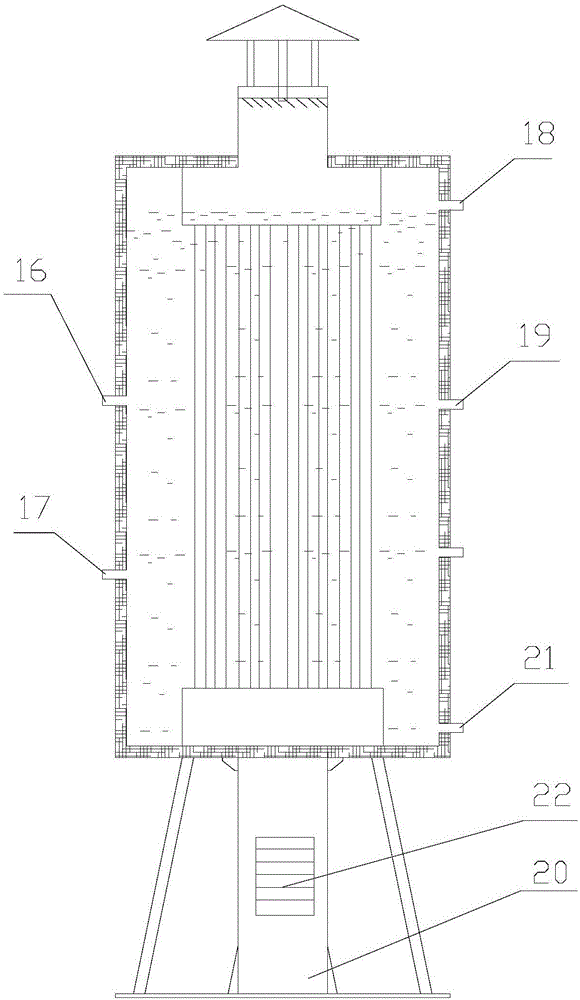

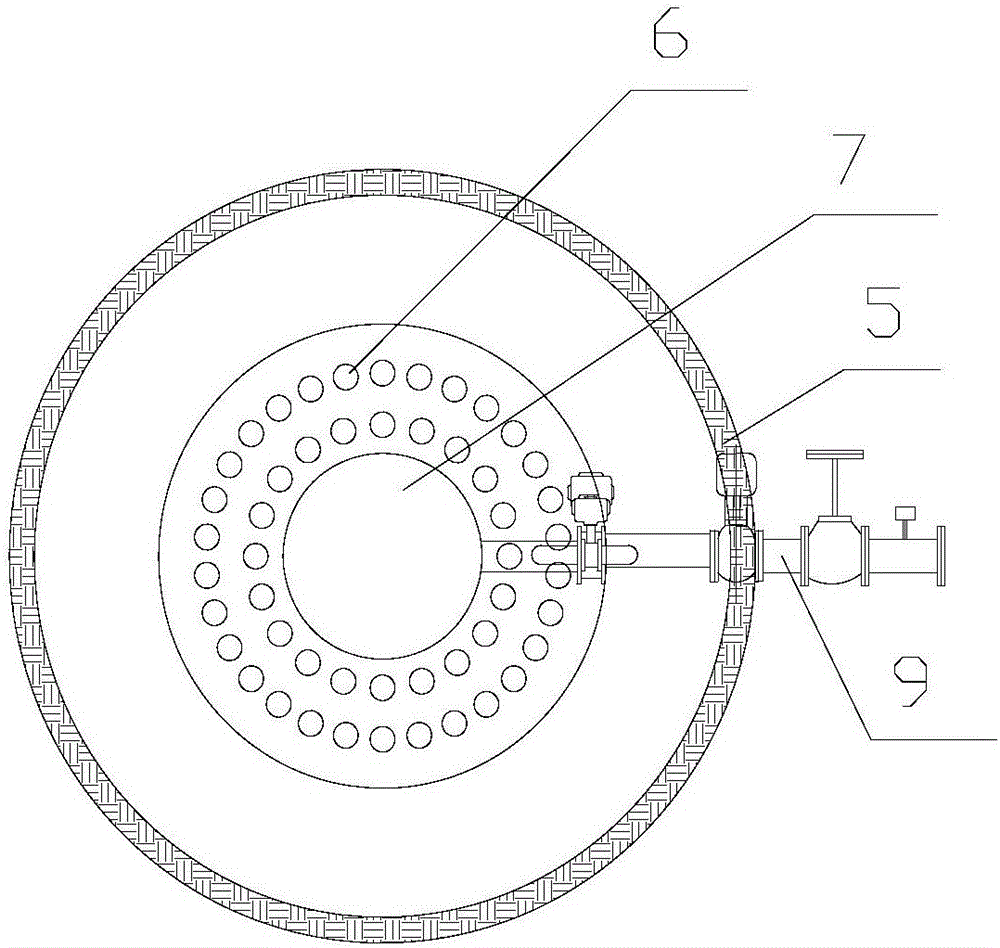

[0023] Such as Figure 1 to Figure 4 As shown, an energy-saving and environment-friendly waste gas treatment hot water heater provided by the present invention includes an air inlet chamber 20, an incineration chamber 7, a heating chamber 5, a smoke exhaust chamber and an electric control cabinet; the air inlet chamber 20 and the incineration chamber 7 In communication, the incineration chamber 7 is installed inside the heating chamber 5 .

[0024] The air inlet chamber 20 is fixed on the lower end surface of the heating chamber 5, and the lower end surface of the heating chamber 5 is also fixed with a bracket 10 arranged around the air inlet chamber 20; the smoke exhaust chamber is fixed on the upper end surface of the heating chamber 5; The air chamber 20 is provided with an incinerator 8 and an axial fan 11, the incinerator 8 is connected to the air supply pipeline 9, and the axial flow fan 11 is fixedly installed on the shutter 22 of the air intake chamber 20; the air supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com