Weapon system composed of multi-section gun tube and fluid-driven spinning projectile and method

A weapon system, a multi-stage technology, applied in barrels, weapon types, offensive equipment, etc., can solve problems such as complex shelling methods, affecting the accuracy of bullet cores, and complex connection methods of bullet holders and bullet cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

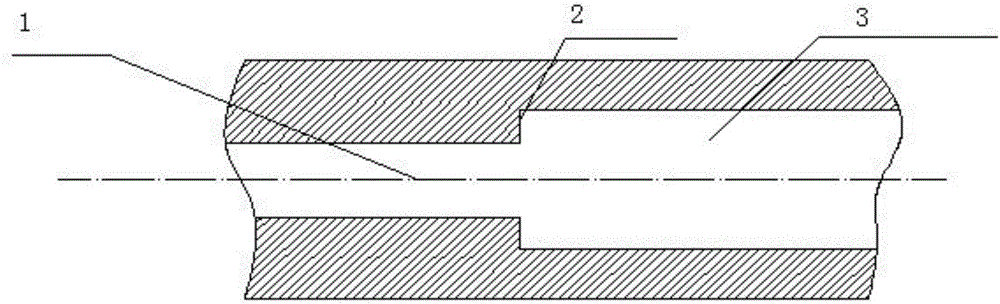

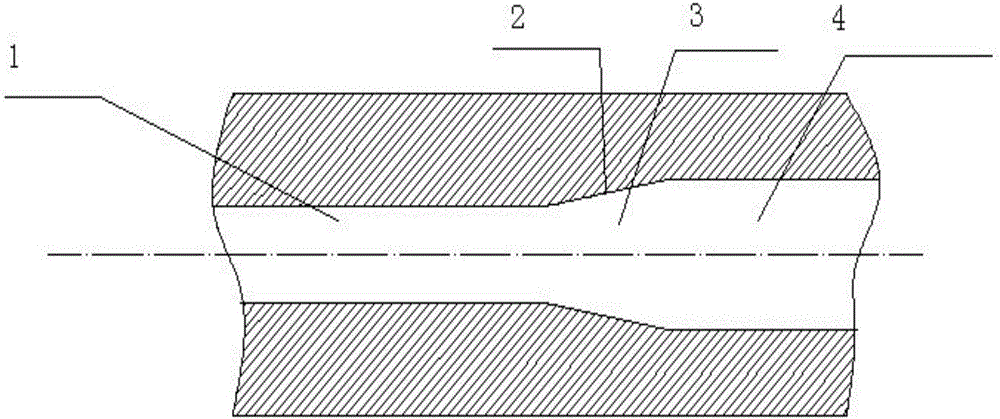

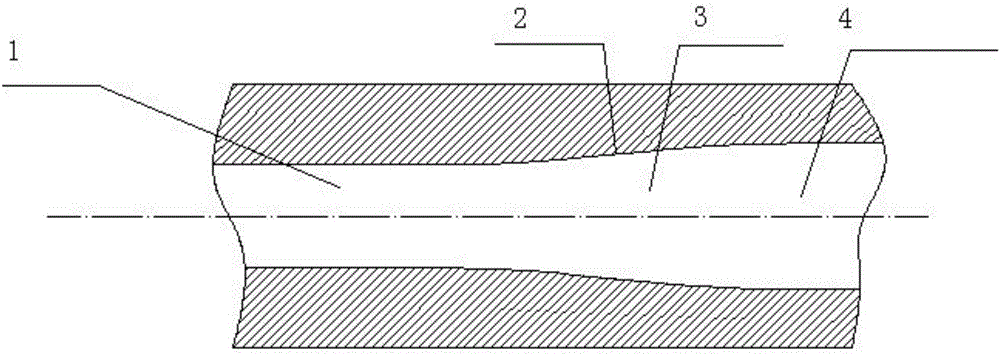

[0095] 1) Smoothbore precursor section + smoothbore transition section;

[0096] 2) Smoothbore precursor section + smoothbore twist section;

[0097] 3) Smoothbore precursor section + smoothbore transition section + smoothbore twisting section;

[0098] 4) Rifling precursor section + rifle transition section;

[0099] 5) Rifle precursor section + rifle clearance fit section;

[0100] 6) The front section of the rifle + the transition section of the rifle + the clearance fit section of the rifle.

[0101] Simultaneously, in each scheme, also can follow a necking section again after the precursor section, that is, the barrel diameter shrinks, and then expands again.

[0102] For the smoothbore barrel, when passing through the precursor section, the projectile seals the propellant gas so as to accelerate the precursor of the projectile; when passing through the twisting section, the propellant gas flows through the volute groove or volute on the projectile or bullet holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com