Automatic analyzing device and sample analyzing method

An automatic analysis device and sample analysis technology, applied in the direction of measuring devices, analysis materials, chemical instruments and methods, etc., can solve the problems of difficult manufacturing, fixed incubation time, large disc or divergent track size, etc., to achieve saving Effects of natural resources and social resources, streamlining the system structure and control process, and reducing the burden on the subjects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

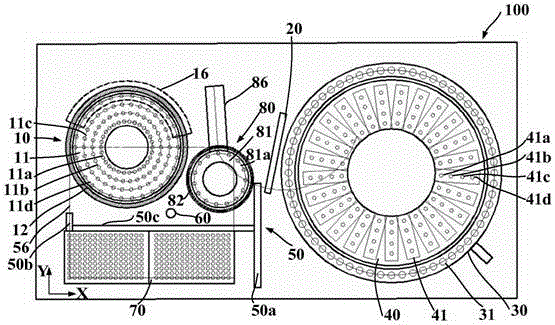

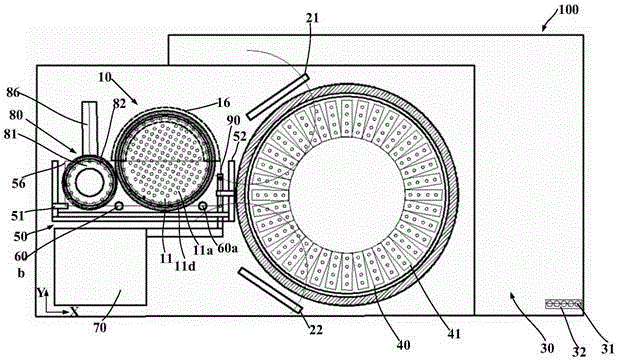

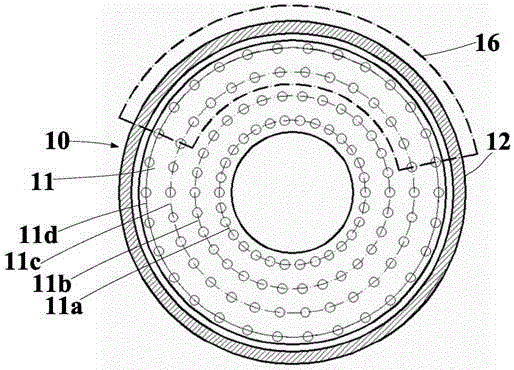

[0030]An automatic analysis device of the present invention, comprising: a filling unit for filling samples or / and reagents into the reaction vessel, a reaction unit for incubating and cleaning and separating the reactants in the reaction vessel, and a measuring unit for measuring the reaction signal in the reaction vessel , the transfer unit is used to transfer the reaction vessel between different positions, the reaction unit includes a rotating device, the reaction container position is set on the rotating device, and is used to carry the reaction container; the measuring unit includes a measuring disc, A reaction vessel position is set for carrying the reaction vessel; at least one reaction vessel position on the rotating device and at least one reaction vessel position on the measuring disc are within the horizontal movement r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com