Lean processing, manufacturing and production technology process sand table based on simulation plane model

A production process and aircraft model technology, applied in the direction of total factory control, total factory control, program control, etc., can solve problems such as low assembly efficiency, chaotic production layout, waste of human resources, etc., and achieve balanced production and management awareness , Guarantee product quality and reduce the number of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

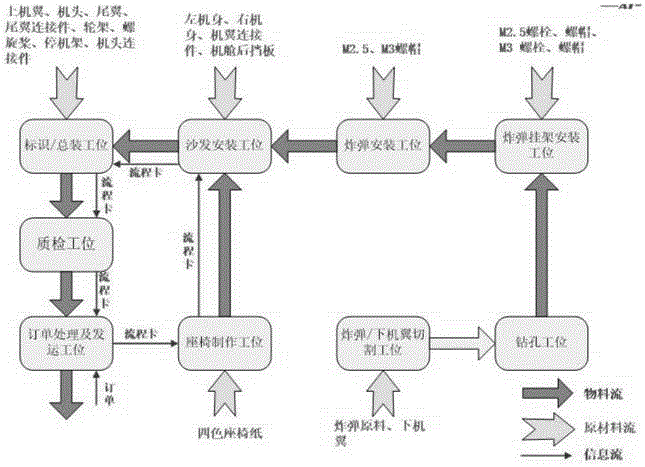

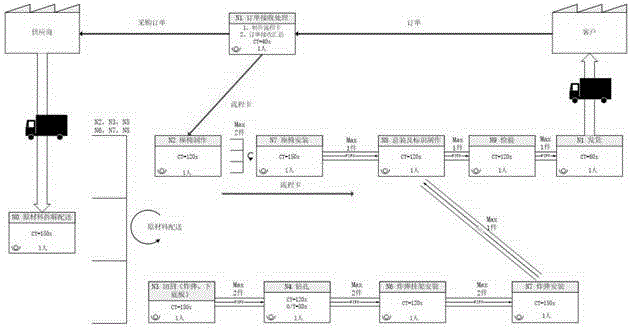

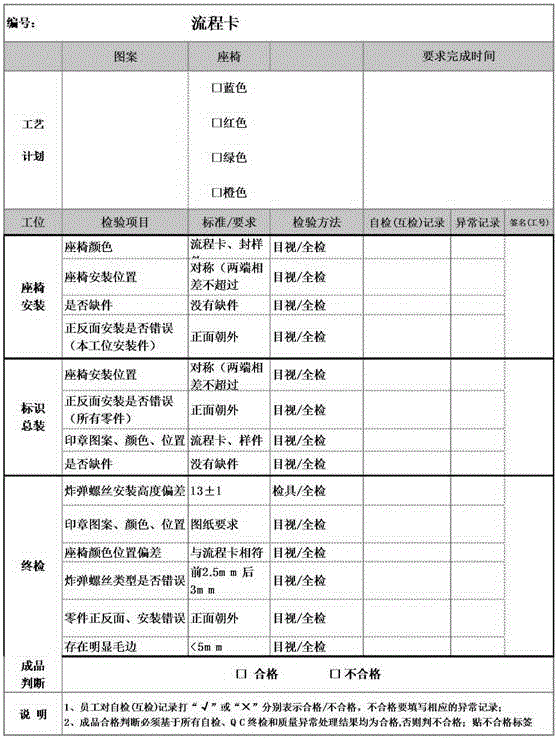

[0032] Please see attached figure 1 , a lean manufacturing production process sand table based on a simulated aircraft model. In the trial production stage, students assemble according to the aircraft assembly flow chart. The specific assembly process of the aircraft includes:

[0033] Step 1: Drilling and cutting of the lower wing plate of the aircraft model, and error checking;

[0034] Step 2: Install the bomb hanger to the lower wing;

[0035] Step 3: Bomb cutting, drilling, installation and dimension error check;

[0036] Step 4: Install the left and right fuselages of the aircraft model;

[0037] Step 5: Fabrication and installation of aircraft model seats;

[0038] Step 6: The upper wing of the aircraft model is stamped and fastened to the lower wing connector;

[0039] Step 7: Install the aircraft model rack plate;

[0040] Step 8: Assembly and installation of aircraft model propeller plates;

[0041] Step 9: Assembly of aircraft model empennage panels and instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com