Design method of forging three-dimensional technique

A technology of process design and manufacturing process, applied in the field of 3D process design, it can solve the problems of poor consistency, inconvenient production, non-unique data sources, etc., and achieve the effect of improving yield, shortening cycle and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

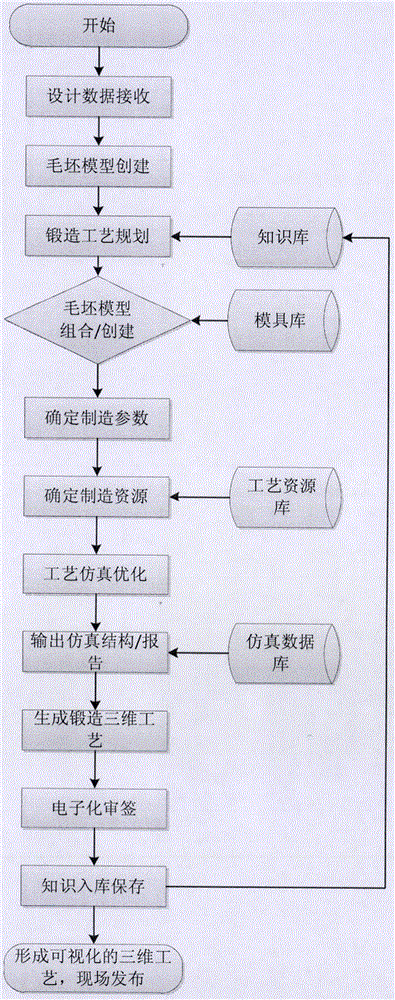

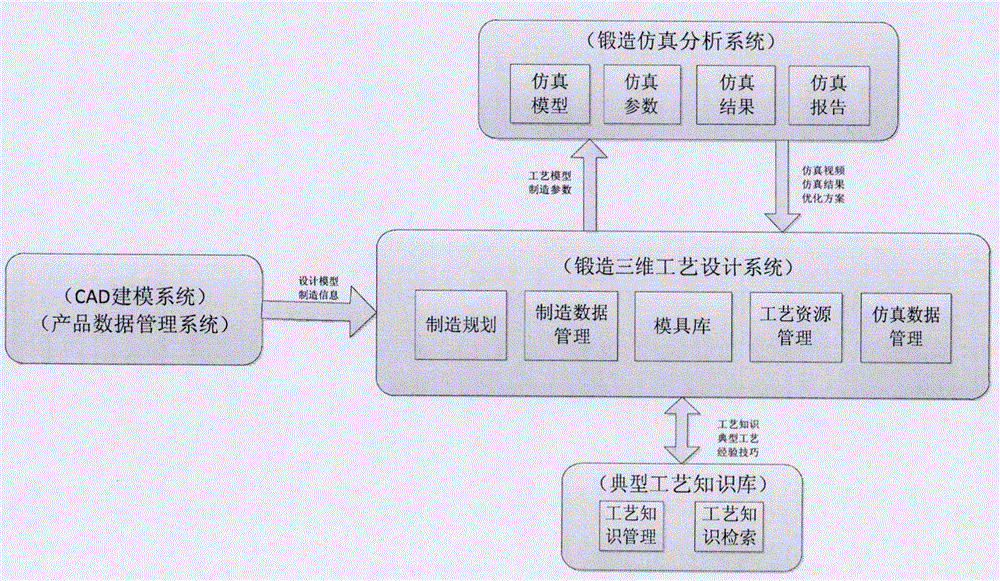

[0014] Such as figure 1 , 2 As shown, the present invention is a forging three-dimensional process design method. On the basis of the manufacturing process management system (MPMS), a set of forging three-dimensional process design system that can possess three-dimensional production capacity is designed, and the system is combined with CAD modeling system, The process simulation analysis system, product data management system and typical knowledge base are integrated. The integrated content includes interface integration, process integration, data integration and knowledge integration between systems. In the integrated forging 3D process design system:

[0015] 1) Receive product data from the design database, including product 3D model, manufacturing information, technical requirements, etc.;

[0016] 2) Open the product design model in the integrated forging 3D process design system, and generate a forging blank model based on the design model combined with manufacturing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com