A kind of semiconductor light-emitting diode and its manufacturing method

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, nano-optics, electrical components, etc., can solve the problems of decreased brightness, difficulty in controlling the opening angle and shape, and the influence of the luminous efficiency of light-emitting diodes, so as to improve the luminous efficiency and improve the quantum The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

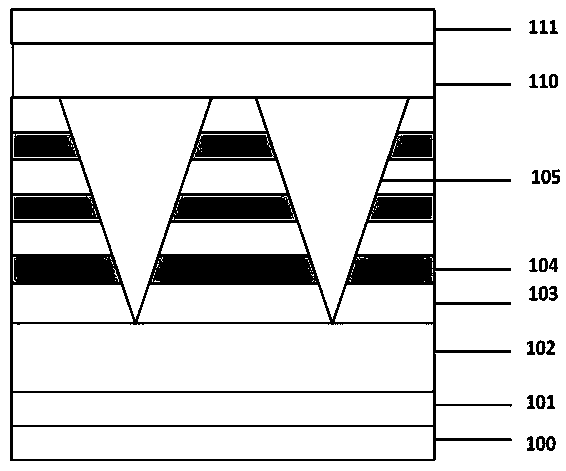

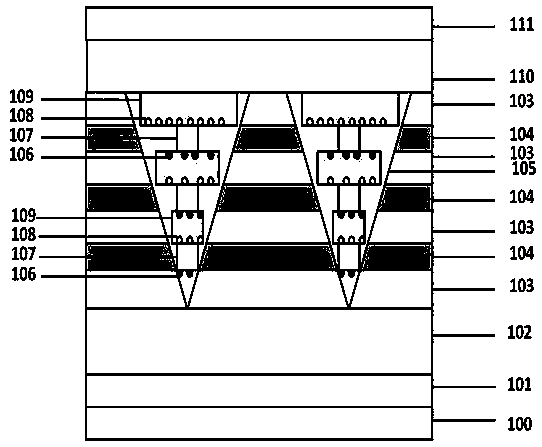

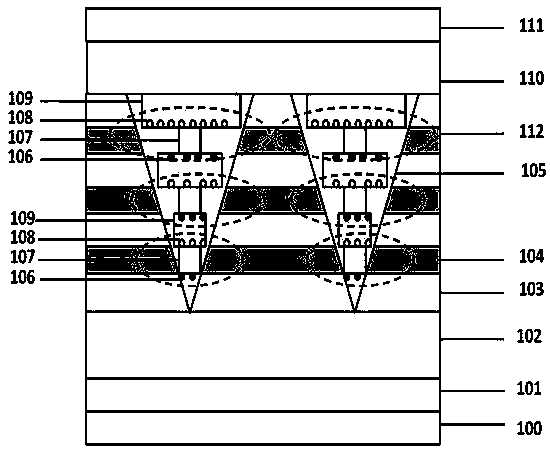

[0026] like Figure 2~3 As shown, it shows a specific embodiment of the present invention. As shown in the figure, a semiconductor light emitting diode disclosed in the present invention, a semiconductor light emitting diode, includes a substrate 100, a buffer layer 101, a first conductivity type first Semiconductor layer 102, an active layer with multiple quantum wells of V-shaped pits, multi-period Al quantum dots 106, AlN nanocolumns 109, Ga quantum dots 108, GaN nanocolumns 109, and a second semiconductor layer 110 of the second conductivity type and a contact layer 111 of the second conductivity type;

[0027] The V-shaped pit positions corresponding to the lower surface, center, and upper surface of the well layer 104 of the quantum well of the active layer have Al quantum dots, AlN nanocolumns, and Ga quantum dots respectively, and the barrier layer 103 of the quantum well of the active layer corresponds to V-shaped pits. There are GaN nanocolumns at the pit position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com