Variable speed pumped storage unit water pump working condition self-start control device and method thereof

A pumped storage and unit technology, applied in the control of electromechanical transmission, motor generator control, electronic commutation motor control, etc., can solve the problems of complex starting process, shock hazards of the unit and power grid, and high price, and achieve good efficiency. Stickiness and estimation accuracy, overcoming the problem of inaccurate orientation, and improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

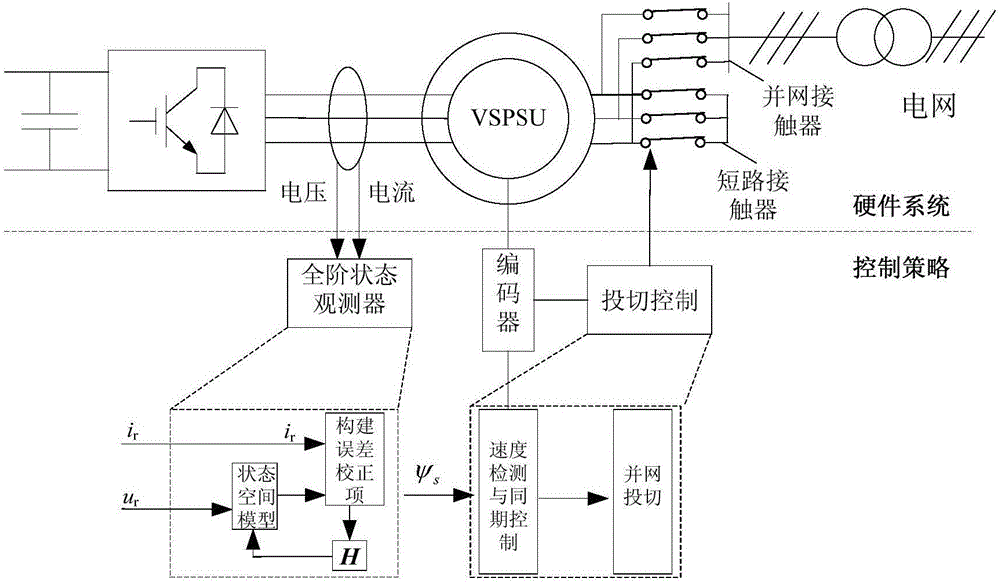

[0039] The invention provides a self-starting control device for pump working conditions of a pumped-storage variable-speed unit, which includes an encoder connected to the pumped-storage variable-speed unit, and connected to the stator of the pumped-storage variable-speed unit for short-circuiting the pumped-storage variable speed The short-circuit contactor of the stator of the unit, and the grid-connected contactor connected to the pumped-storage variable-speed unit and used to control the synchronization of the pumped-storage variable-speed unit;

[0040] Further, the encoder is used to detect the rotor speed of the variable-speed unit and to operate the grid-connected synchronization control of the variable-speed unit.

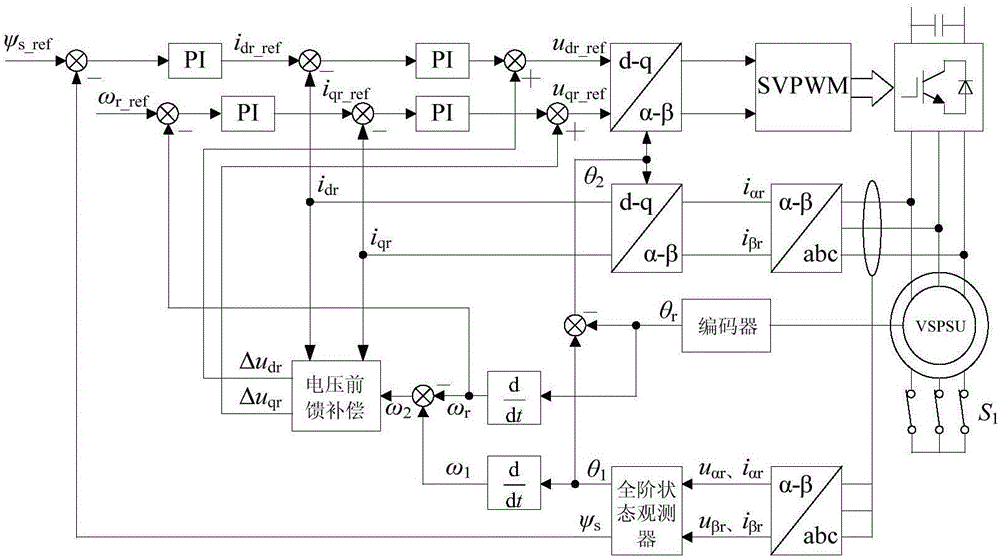

[0041] A self-starting control method for pump working conditions of a pumped-storage variable speed unit, the method includes the following steps:

[0042] Step 1: Stator short-circuit double closed-loop control; short-circuit the stator through a short-circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com