Integrated hat making technology, and hat made through technology

A production process and technology for hats, applied to hats, hat products, head coverings, etc., can solve the problems of high production cost, waste of production materials, and single appearance, so as to reduce production cost, improve production speed, and improve appearance. Image change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The manufacturing process of the integrally formed hat comprises the following steps:

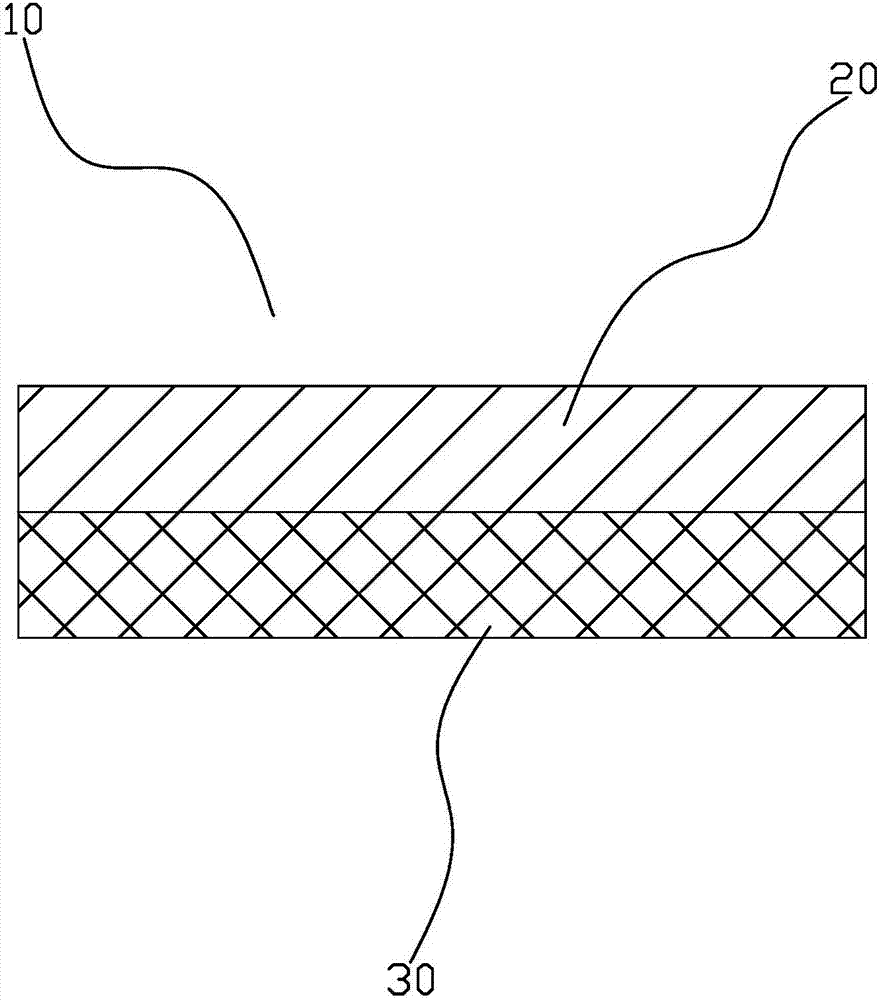

[0038]1) Make cloth A10 and a shaping mold, the face cloth B20 is selected as cotton material, and the lining C is selected as a woven piece made of shaped yarn, firstly, an adhesive is applied on the face cloth B20 and / or the lining C30 , and then lightly paste the face cloth B20 on the inner cloth C30 and lightly press the two, and bond the two to form the cloth A10 through the adhesive on the face cloth B20 and / or the inner cloth C30. Here, preferably Generally, when extruding the surface cloth B20 and the inner C30 tightly together, the temperature is 10-110°C, the extrusion pressure is 0.3-0.6MPa, and the time is 5-90 seconds. In addition, a hat matching the shape of the hat is made The stereotyped mold, the shape of the stereotyped mold can be changed freely, specifically can be determined according to the shape of the hat that needs to be made;

[0039] 2) Cutting, cutting th...

Embodiment 2

[0044] The manufacturing process of the integrally formed hat comprises the following steps:

[0045] 1) Make cloth A10 and a shaping mold. The face cloth B20 is selected as wool, and the lining C is selected as a woven piece made of shaped yarn. First, an adhesive is applied on the face cloth B20 and / or the lining C30, Then the surface cloth B20 is lightly pasted on the lining C30 and lightly pressed, and the two are bonded to form the cloth A10 by the adhesive on the surface cloth B20 and / or the lining C30. Here, preferably When extruding the surface cloth B20 and the inner C30 closely together, the temperature is 10-100°C, the extrusion pressure is 0.3-0.5MPa, and the time is 5-100 seconds. In addition, a hat matching the shape of the hat is also made Sizing mold, the shape of the said sizing mold can be changed freely, specifically can be determined according to the shape of the hat that needs to be made;

[0046] 2) Cutting, cutting the fabric A10 obtained in step 1) int...

Embodiment 3

[0051] The manufacturing process of the integrally formed hat comprises the following steps:

[0052] 1) Make cloth A10 and a shaping mold, the face cloth B20 is selected as fiber, and the lining C is selected as a woven sheet made of shaped yarn, firstly, an adhesive is applied on the face cloth B20 and / or the lining C30, Then the surface cloth B20 is lightly pasted on the lining C30 and lightly pressed, and the two are bonded to form the cloth A10 by the adhesive on the surface cloth B20 and / or the lining C30. Here, preferably , when extruding the surface cloth B20 and the inner C30 close together, the temperature is 40-180°C, the extrusion pressure is 0.3-0.7MPa, and the time is 10-80 seconds. In addition, a hat matching the shape of the hat is also made. Sizing mold, the shape of the said sizing mold can be changed freely, specifically can be determined according to the shape of the hat that needs to be made;

[0053] 2) Cutting, cutting the fabric A10 obtained in step 1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com