Preparation method of nanometer cu2o/ag/tio2-iron modified zeolite composite photocatalyst

A composite light and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve problems such as difficult separation, improve efficiency and have good application prospects , the effect of large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

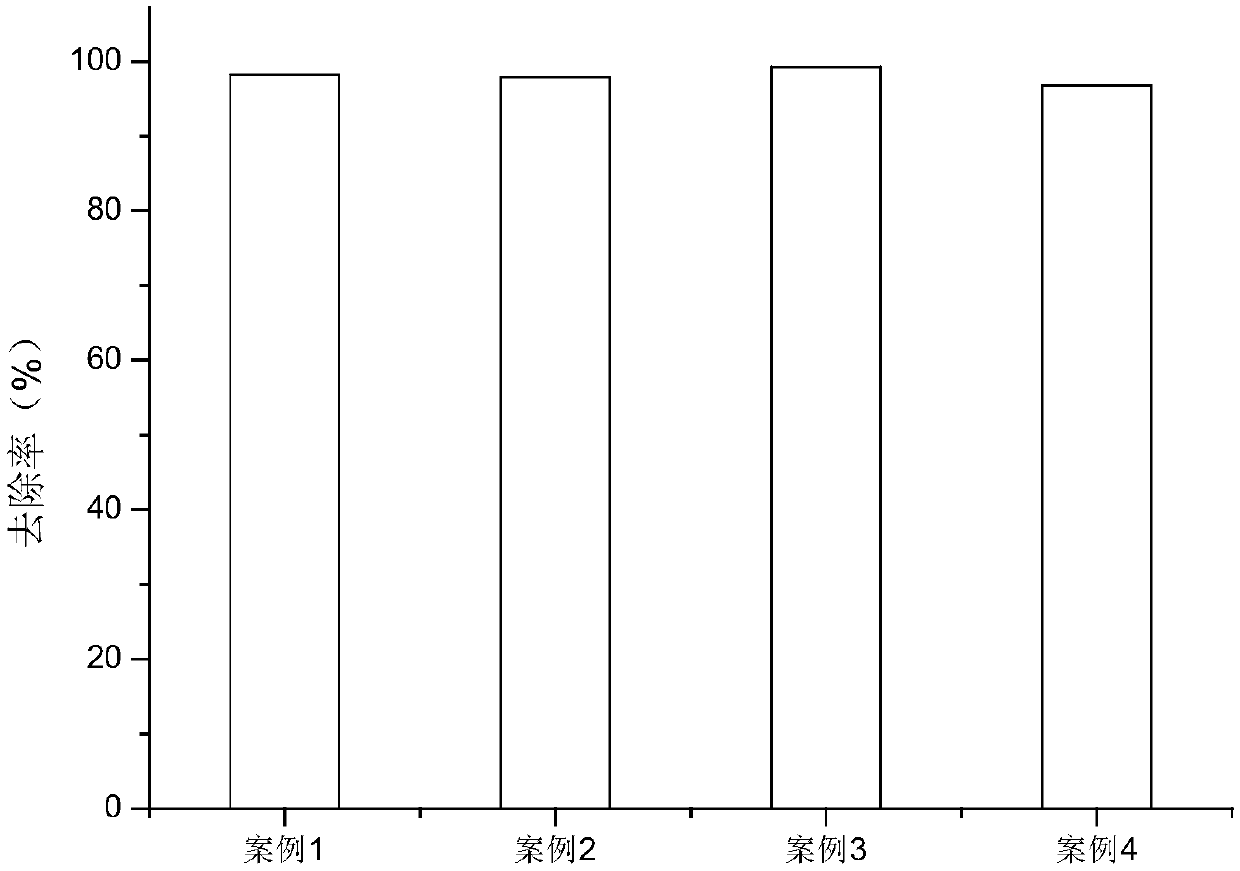

Examples

Embodiment 1

[0025] Nano-Cu in this embodiment 2 O / Ag / TiO 2 -The preparation method of iron-modified zeolite composite photocatalyst, specifically comprises the following steps:

[0026] (1) Disperse 5 g of artificial zeolite A in 50 mL of 10 mol / L NaOH solution, and stir at 100 ° C for 1 hour to form a zeolite precursor;

[0027] (2) Preparation of nano Cu 2 O, Ag and TiO 2 Mix the aqueous solution, and then fully mix with the zeolite precursor to prepare a mixed gel;

[0028] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0029] (4) The intermediate is fully mixed with 50 mL of 4mol / L ferric chloride solution, after separation, washing and drying, and then calcined at high temperature to obtain the described nano-Cu 2 O / Ag / TiO 2 - Iron-modified zeolite composite photocatalyst.

[0030] In step (1), the amount of zeolite added in the alkali solution is: 0.0...

Embodiment 2

[0036] Nano-Cu in this embodiment 2 O / Ag / TiO 2 -The preparation method of iron-modified zeolite composite photocatalyst, specifically comprises the following steps:

[0037] (1) Disperse 10 g of artificial zeolite X in 100 mL of 12 mol / L NaOH solution, and stir at 120 ° C for 3 hours to form a zeolite precursor;

[0038] (2) Preparation of nano Cu 2 O, Ag and TiO 2 Mix the aqueous solution, and then fully mix with the zeolite precursor to prepare a mixed gel;

[0039] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0040] (4) The intermediate is fully mixed with 100mL of 5mol / L ferric nitrate solution, separated, washed and dried, and then calcined at high temperature to obtain the nano-Cu 2 O / Ag / TiO 2 - Iron-modified zeolite composite photocatalyst.

[0041] In step (1), the amount of zeolite added in the alkali solution is: 0.008g of zeolite is...

Embodiment 3

[0046]Nano-Cu in this embodiment 2 O / Ag / TiO 2 -The preparation method of iron-modified zeolite composite photocatalyst, specifically comprises the following steps:

[0047] (1) Add the silicon source and the aluminum source into the alkali solution, mix thoroughly, and form a zeolite precursor under a certain temperature condition;

[0048] (2) Nano-Cu 2 O, Ag and TiO 2 Add to the zeolite precursor and mix thoroughly to make a mixed gel;

[0049] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0050] (4) The intermediate is fully mixed with the iron salt solution, separated, washed and dried, and then calcined at a high temperature to obtain the nano-Cu 2 O / Ag / TiO 2 - Iron-modified zeolite composite photocatalyst.

[0051] In step (1), the molar ratio of silicon source, aluminum source and alkali solution is 1:2:200. The silicon source is silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com