A kind of synthesis technique of organic synthesis intermediate cyclohexanone ethylene glycol ketal

A cyclohexanone ethylene glycol ketal and organic synthesis technology, applied in organic chemistry, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of severe equipment corrosion, low product purity, and many side reactions, etc. Achieve the effects of easy access, good yield, and reduced side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

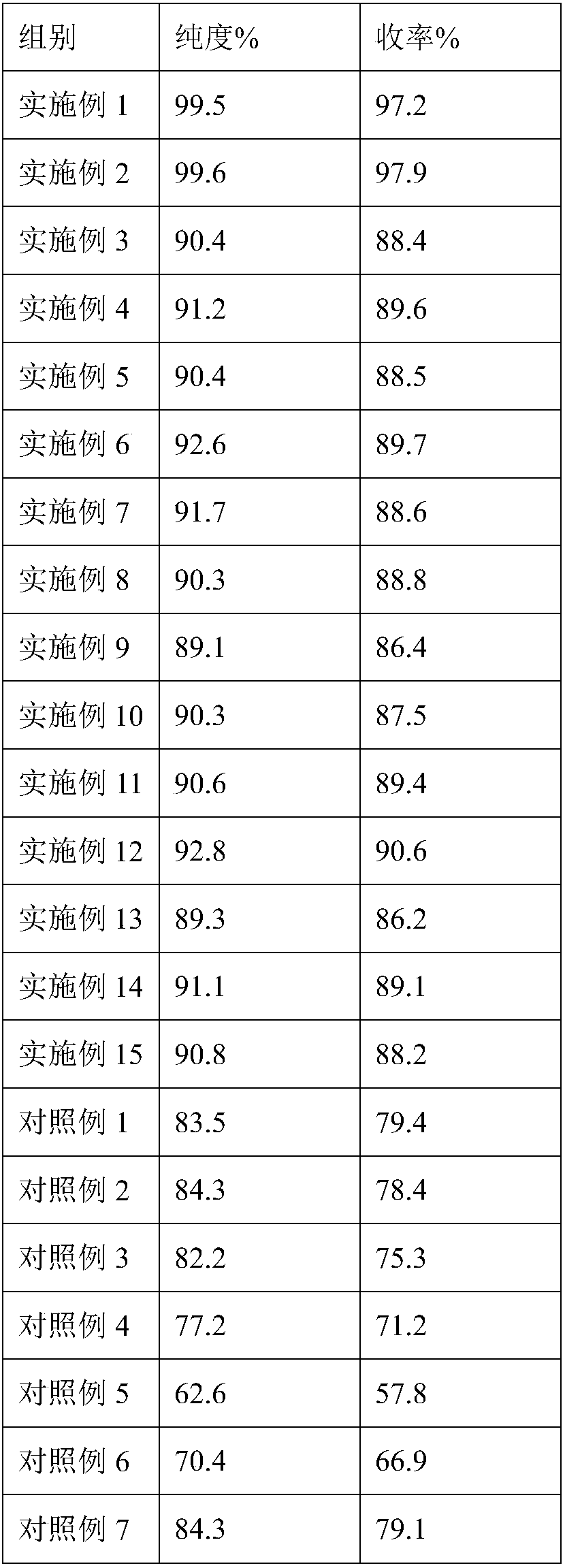

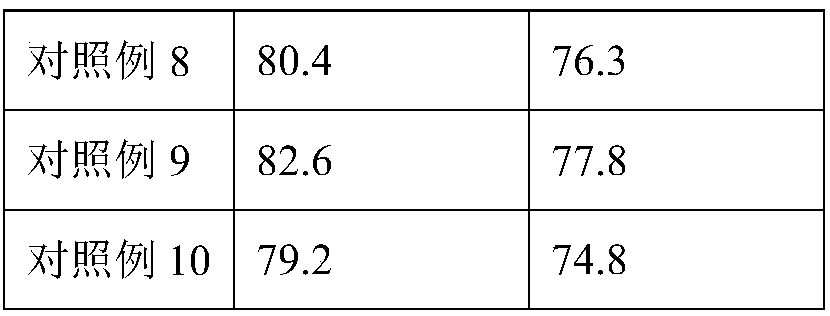

Examples

Embodiment 1

[0021] The preparation of solid acid catalyst is as follows:

[0022] Step 1. First, 10g of Al2O3 is ultrasonically treated at 120°C for 3 hours in a nitrogen atmosphere;

[0023] Step 2, then mix the treated Al2O3 with 65% H2SO4 solution according to the ratio of solid to liquid mass ratio of 1:12, and reflux and stir for 8 hours;

[0024] Step 3. After reflux and stirring, then stand still for 5 hours, centrifuge, and dry to constant weight at 110°C to obtain Al2O3 as a catalyst active carrier;

[0025] Step 4. Mix the active Al2O3 and 0.5mol / L Fe2(SO4)3 solution at a mass ratio of 1:8, and reflux and stir for 5 hours;

[0026] Step 5, vacuum filtration and separation, the separated solid was mixed with Fe2(SO4)3 solution of the same concentration and volume, and refluxed and stirred for 5 hours under the same conditions, centrifuged and dried at 110°C to constant weight;

[0027] Step 6, using the impregnation method, impregnating the catalyst initially prepared in the pr...

Embodiment 2

[0036] Prepare cyclohexanone, ethylene glycol, and cerium-modified nanoscale composite Fe2(SO4)3 / Al2O3 solid acid catalyst with a mass ratio of 30:32:0.5. Cyclohexanone 30g, ethylene glycol 32g, cerium-modified nano-composite Fe2(SO4)3 / Al2O3 solid acid catalyst 0.5g, water agent cyclohexane 25ml. The operation steps are the same as in Example 1.

Embodiment 3

[0038] Prepare cyclohexanone, ethylene glycol, and cerium-modified nanoscale composite Fe2(SO4)3 / Al2O3 solid acid catalyst with a mass ratio of 40:38:0.5. Cyclohexanone 40g, ethylene glycol 38g, cerium-modified nanoscale composite Fe2(SO4)3 / Al2O3 solid acid catalyst 0.5g. Other raw materials, operation steps are the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com