Novel plastic marking machine

A scribing machine and plastic technology, which is applied to sports accessories, ski binding, roads, etc., can solve the problems of inconvenient transportation, transition, failure to meet quality requirements, and burrs in the scribing effect. Guaranteed construction quality and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

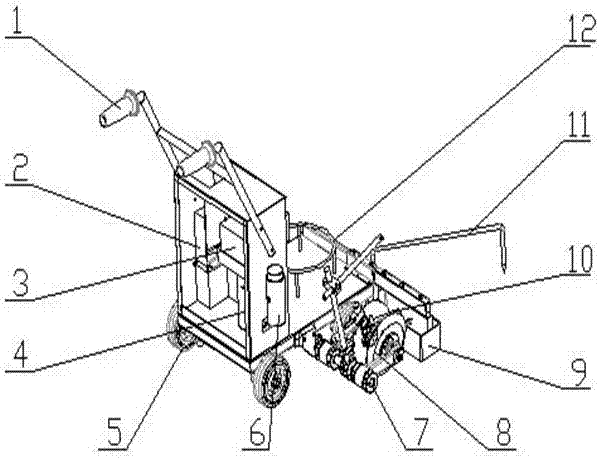

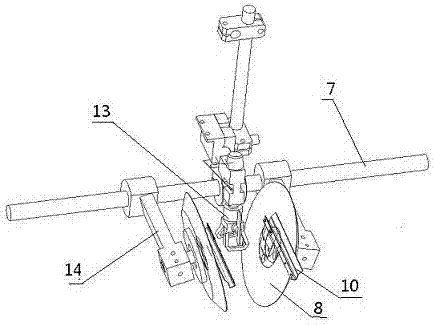

[0015] Accompanying drawing is a kind of specific embodiment of the present invention.

[0016] The novel plastic scribing machine of the present invention includes a vehicle frame, a lithium battery 2 installed behind the vehicle frame, a motor 4, a diaphragm pump 3, a buffer tank 6, and a scribing chuck mechanism, and is characterized in that: the lithium battery 2 The wire is connected to the motor 4, and the motor 4 is driven to connect the diaphragm pump 3, the inlet pipe of the diaphragm pump 3 is connected to the material barrel, the outlet pipe of the diaphragm pump 3 is connected to the buffer tank 6, and the outlet of the buffer tank 6 is connected to the spray gun 13 through a high-pressure pipe; The line paint is sprayed onto the marking chuck mechanism, which includes a fixed shaft 7, a chuck 8, a scraper 10 and a recovery box 9, the fixed shaft 7 is installed on the side of the vehicle frame, and the fixed shaft 7 passes through the swing arm Two opposite chucks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com