A 3D printed personalized cage dental bone graft guide

A 3D printing, cage-like technology, applied in the direction of skull, bone implants, etc., can solve the problem of poor plasticity of bone meal, and achieve the effect of reducing use, improving quality and speed, and reducing the difficulty of clinical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

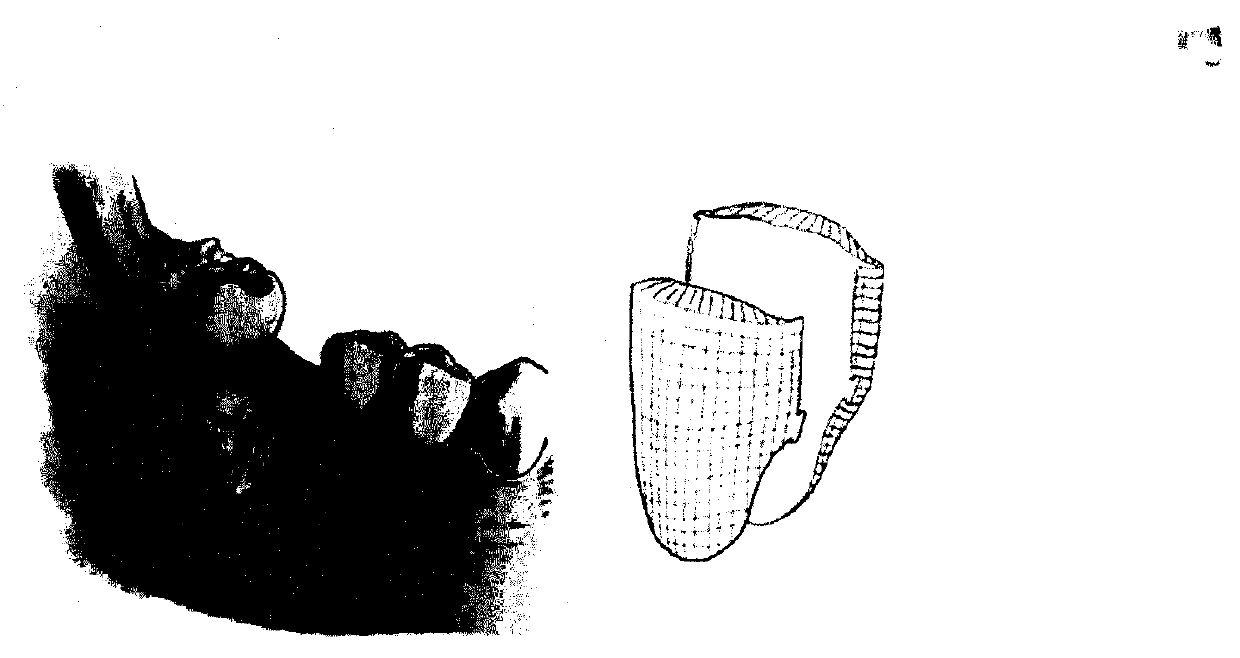

[0018] A 3D printed personalized cage-shaped dental bone graft guide plate, characterized in that: the shape of the bone defect area is reconstructed by three-dimensional modeling, the bone graft guide plate is a cage-like structure, and a part is in contact with the bone defect part of the alveolar bone The cage is used to guide the implantation of bone meal, and the other part is the cage cover that is in contact with the soft tissue to restore the contour of the gums.

[0019] Mandibular first molar bone grafting is taken as an example. The implementation of a 3D printed personalized cage-shaped dental bone grafting guide includes the following steps:

[0020] (1) Firstly, for the bone defect in the mandibular first molar area of the patient, three-dimensional reconstruction is performed based on CT imaging technology, and the size and shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com