A continuous evaporation crystallizer and evaporation system for light solids

A technology for evaporating crystallizers and solids, which is applied in the field of continuous evaporating crystallizers and evaporation systems, can solve the problems of massive deposition of solid calcium propionate, inability to realize large-scale continuous and stable production, etc., and achieves the effect of simple structure and increased concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

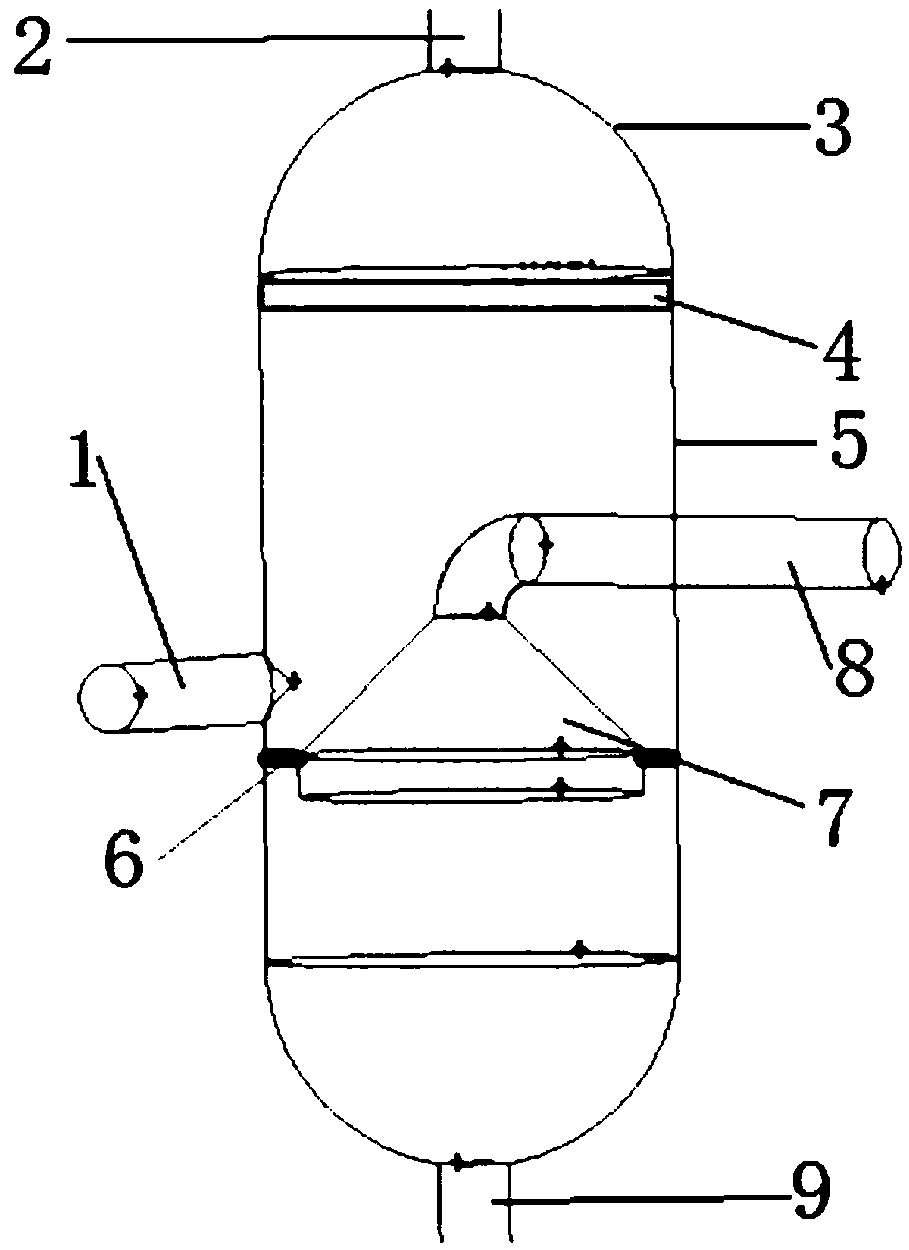

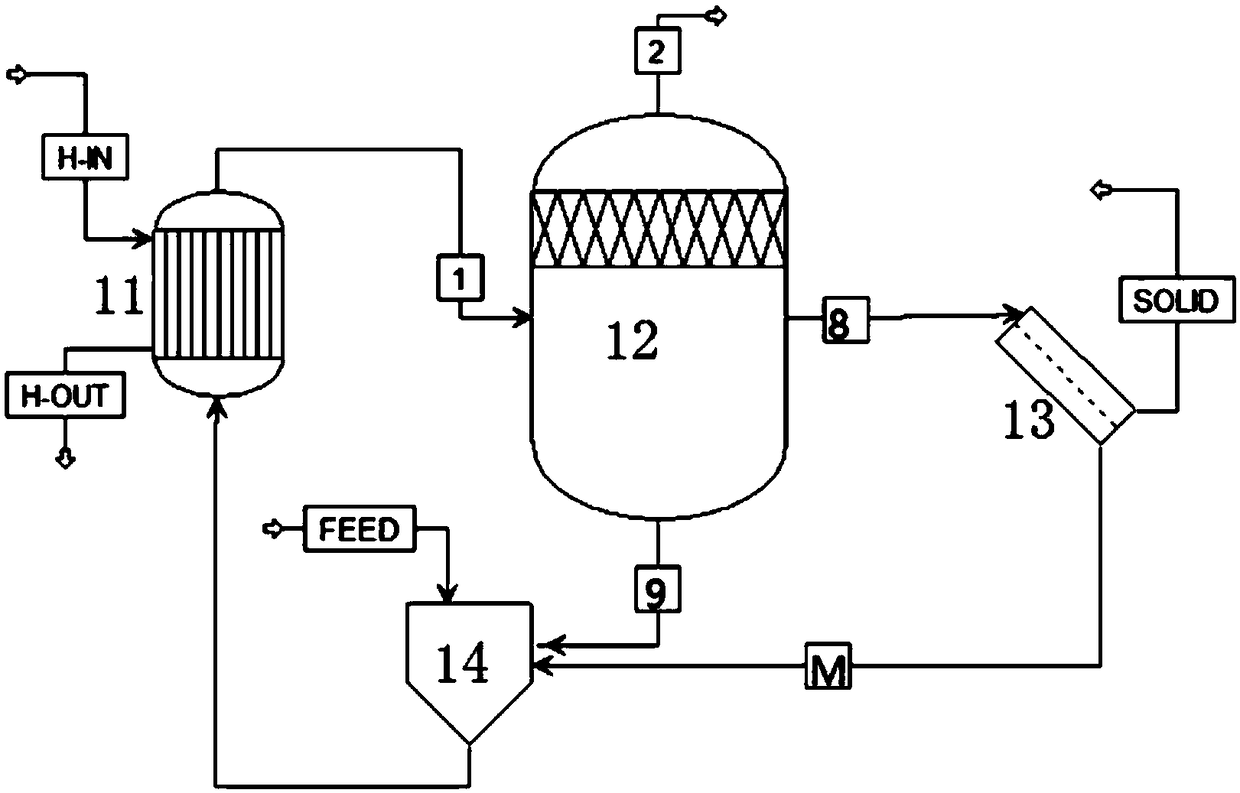

[0023] A continuous evaporation crystallizer for light solids such as figure 1 As shown, it includes a tank body, a feed port 1 arranged on the tank body, a steam outlet 2, a liquid outlet 9, a magma extraction pipe 8, and a demister 4 arranged in the tank body, and the feed port 1 It is arranged in the middle of the tank body, the steam outlet 2 is arranged at the upper end of the tank body 1, the liquid outlet 9 is arranged at the lower end of the tank body 1, and the middle part of the tank body is provided with a flared mouth 7, and the large opening of the flared mouth 7 faces Down, the small opening is upward, and one end of the crystal slurry extraction pipe 8 located in the tank body is connected with the small opening of the horn-shaped flare 7. The space above the flared mouth 7 is a gas-liquid separation zone, and the space below the flared mouth 7 is a liquid-solid separation zone.

[0024] Wherein, the tank body includes a cylinder body 5 and a head 3 connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com