Latex stirring device of CT carton packer

A technology of machine latex and packaging, applied in the field of latex stirring device of CT box packaging machine, can solve problems such as environmental pollution and latex skinning on the surface, reduce maintenance time, ensure latex dilution and fluidity, and reduce latex knots. The effect of skin phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

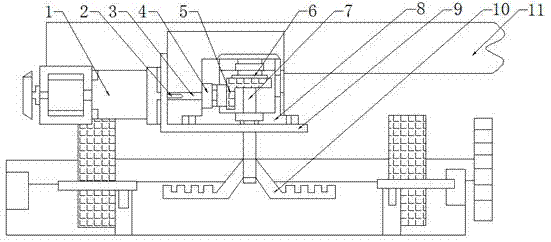

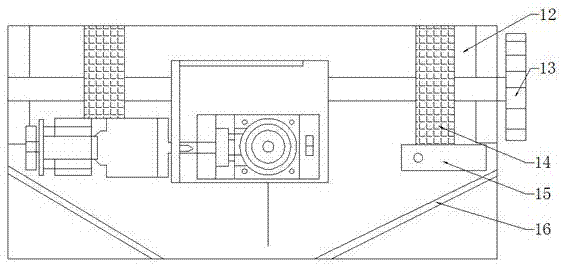

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Such as Figure 1-Figure 2 As shown, it includes a rubber cylinder 12, a gear 13, a rubber roller 14, and a scraper 15. The scraper 15 is provided with a partition 16, and the upper side of the glue tank 12 is provided with an agitator 10, and the upper side of the agitator 10 is provided with a bracket. 9. It is used to install the motor 1 and the box body 8. The box body 8 is arranged on the upper side of the bracket 9. The box body 8 is made of aluminum alloy and fixed on the bracket 9. It is used for the installation, positioning and support of the transmission parts. On the box body 8 The side is provided with a vertical shaft 7, and the vertical shaft 7 is driven by a conical bevel gear to rotate. The upper side of the vertical shaft 7 is provided with a large bevel gear 6, one side of the vertical shaft 7 is provided with a small bevel gear 5, and one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com