A kind of nano-palladium-based catalyst and its preparation and application

A catalyst, nano-palladium technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of lack of two-way catalysts, and achieve the effect of high industrial practical application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1. Preparation of Pd / NMC catalyst:

[0026] Put 3.25g ZrOCl in a 1L beaker at 35℃ 2 ·8H 2 O and 20.0 g P123 were dissolved in a solution of 130 mL 37% HCl and 650 mL water. Add 42.50g of ethyl orthosilicate and stir for 24h. Then, let it stand for 24 hours at 100°C. The precipitate was filtered, washed with a small amount of ethanol, and dried overnight at room temperature. Dry in an oven at 60°C for 12 hours. The temperature was raised to 550°C at a rate of 2°C / min and calcined in air for 4 hours to remove the P123 surfactant to obtain Zr-SBA-15. Mix 15.0 g of xylene, 15.0 g of furan methanol and 0.1 g of oxalic acid for later use. Weigh 14.0g of Zr-SBA-15 template into a 250mL beaker, stir with a glass rod, and add dropwise the polymer solution prepared above. Polymerize in an oven at 60°C for 24 hours and at 90°C for 24 hours to obtain a polyfuran methanol-SBA-15 complex. Raise the above-mentioned polyfuran methanol-SBA-15 compound in ammonia at a heating ...

Embodiment 2

[0027] Example 2. The process of catalyzing the decomposition of potassium formate to produce hydrogen:

[0028] Step 1: First put 20mg of catalyst into the reactor, add a certain concentration of potassium formate solution, and quickly put it into a constant temperature water bath heated to the required temperature, turn on the stirring after the heat balance, and continuously obtain gas.

[0029] Step 2: Quantify the obtained mixed gas through the gas pipe.

Embodiment 3

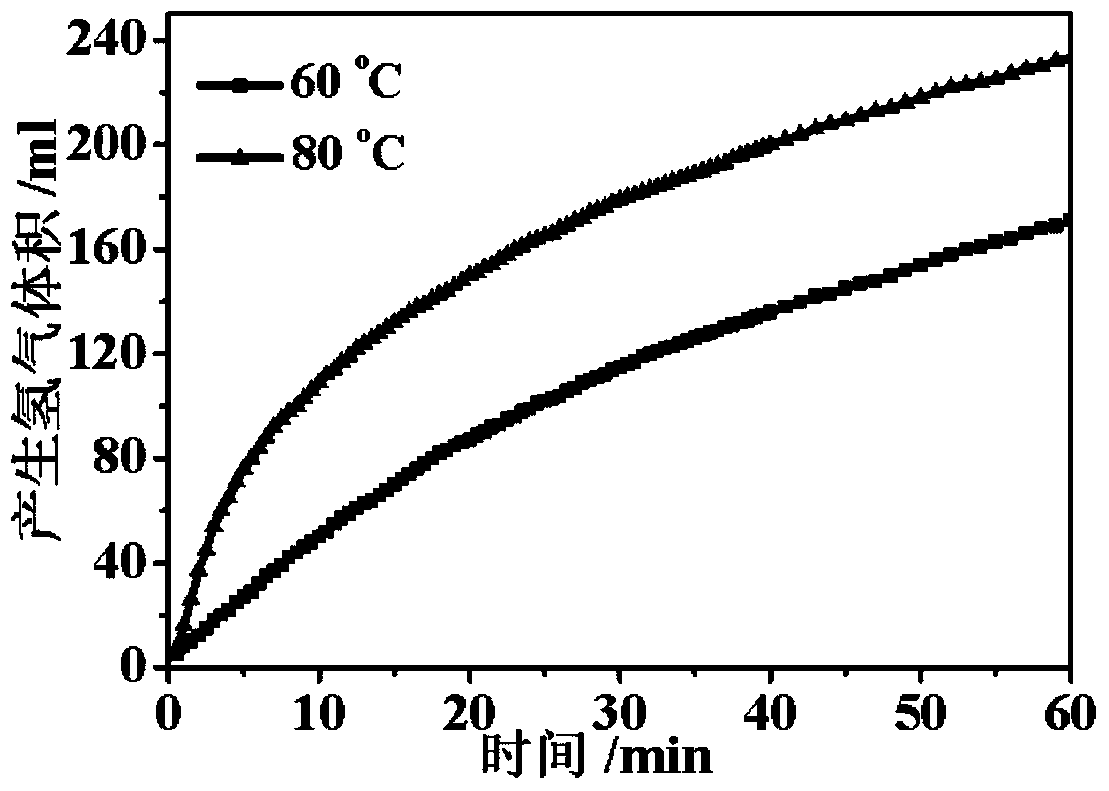

[0030] Example 3. Investigate the performance of Pd / NMC to catalyze the decomposition of potassium formate to produce hydrogen at different reaction temperatures:

[0031] The Pd / NMC catalyst prepared in Example 1 (the mass loading of palladium is 5% and the amount of nitrogen incorporated is 9%) was tested according to Example 2. The formic acid was carried out at 60°C and 80°C respectively. Potassium decomposition reaction, the solution used is 6ml 2mol / L potassium formate aqueous solution, the reaction result is shown figure 1 .

[0032] From figure 1 It can be seen that Pd / NMC can effectively decompose potassium formate aqueous solution at 60℃, and the initial conversion frequency is 1589h -1 . After raising the temperature to 80°C, the catalytic activity is further improved, about twice that at 60°C, and the initial conversion frequency is increased to 3377h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com